TABLET DIES AND PUNCHES

Product Details:

- Type TABLET DIES AND PUNCHES

- Material Stainless Steel

- Computerized No

- Control Mode Manual

- Weight (kg) 1.5 Kilograms (kg)

- Dimension (L*W*H) 254 x 254 Millimeter (mm)

- Color silver

- Click to View more

TABLET DIES AND PUNCHES Price And Quantity

- 20 Unit

- 1200.00 INR

TABLET DIES AND PUNCHES Product Specifications

- one year warranty

- 254 x 254 Millimeter (mm)

- 1.5 Kilograms (kg)

- Manual

- silver

- Stainless Steel

- TABLET DIES AND PUNCHES

- No

TABLET DIES AND PUNCHES Trade Information

- MUMBAI JNPT PORT

- 100 Unit Per Month

- 4-6 Week

- SEA WORTHY PACKING

- Australia North America South America Eastern Europe Western Europe Middle East Africa Central America Asia

- All India

Product Description

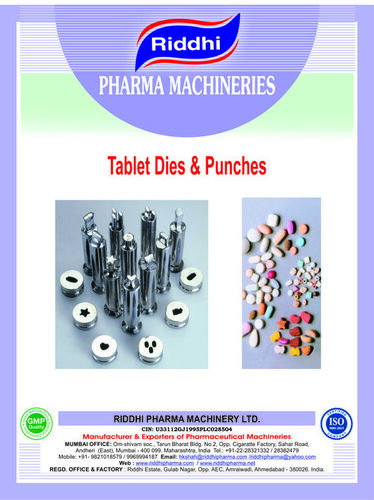

TABLET PUNCHES and DIES

We are one of the pioneer Pharmaceutical Machinery Manufacturers from India, We manufacture Tablet Dies and Punches or Tablet Tooling, they are manufactured under strict Quality Control and all the quality parameters if or ok , then the Dies & Punches are send for Despatch we follow the manufacturing process according to the rule book. Tablet Dies and Punches can manufactured in several shapes and sizes, we manufacture Tablet Dies Punches for D tooling, B tooling, BB tooling Machine.

We offer solution with pharmaceutical industry demands in mind. Our high quality punches and dies support tablet manufacturing on a daily basis. Our high quality and expedited deliveries are well known making us a leader in the industry. We manufacture punches and dies with quality and cost in mind. Our valuable experience and ability to troubleshoot allows us the ability to improve on original designs.

We are confident in our commitment to continually offer our customers the ne west technological advances at a fraction of the expected cost. We pass the sesavings along to our customers with their demands and expectations in mind. Our stringent incoming steel quality control procedures are as strict as most pharmaceutical raw material quality programs. No steel is cut before laboratory analysis to confirm the quality. This assures confidence that we are providing our customers with punches and dies made of finest materials to extend the life of our punches and dies. Our precise tools manufactured by latest CNC technology, CNC & PLC grinding machines. Our well finished Die &punches are finished by German make Lapping machines. Our facilities include the latest "state of the art" production and quality-control equipments, allowing us to meet our customer's highest specifications, while at the same time, assuring quick delivery. We have achieved an international reputation for high-quality performance and reliability.

Used of latest CAD system coupled with our expert design engineers allows both simple and complex designs to be rapidly developed and processed ensuring complete repeatability and accuracy. Fully documented inspection reports are produced at all the steps of manufacturing of the Tolls, which confirm that your order has been inspected and is in accordance with the contract conditions.