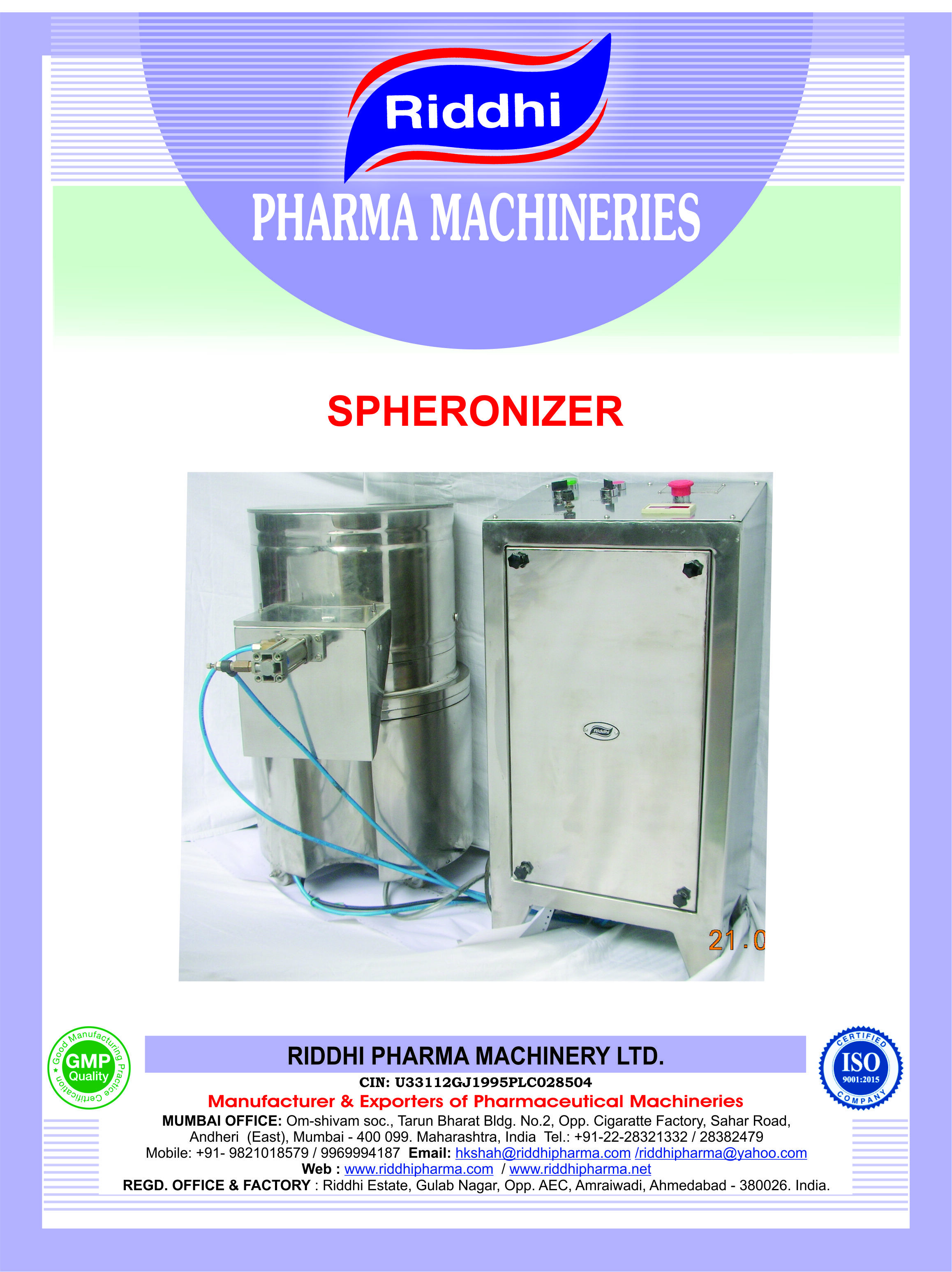

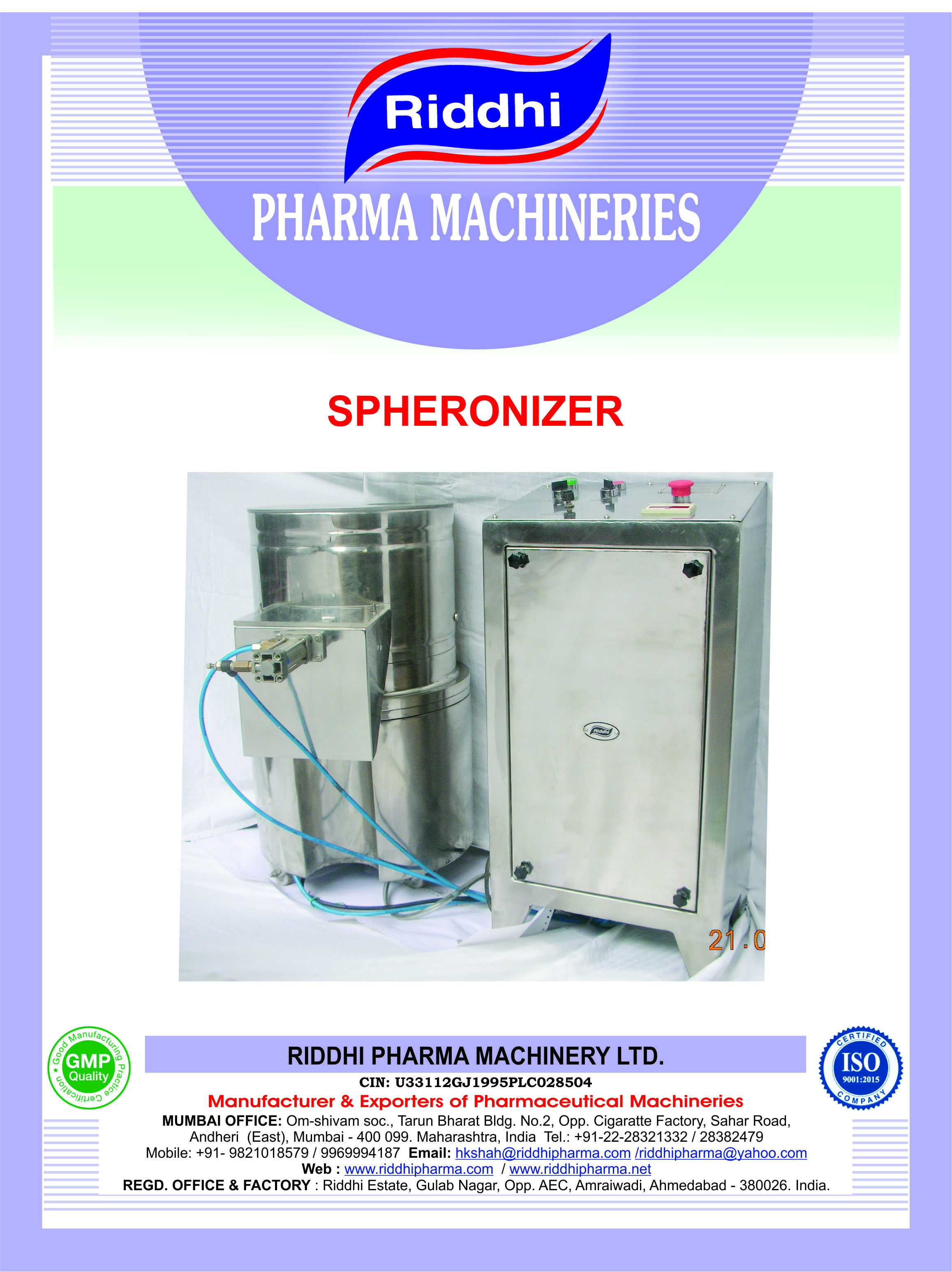

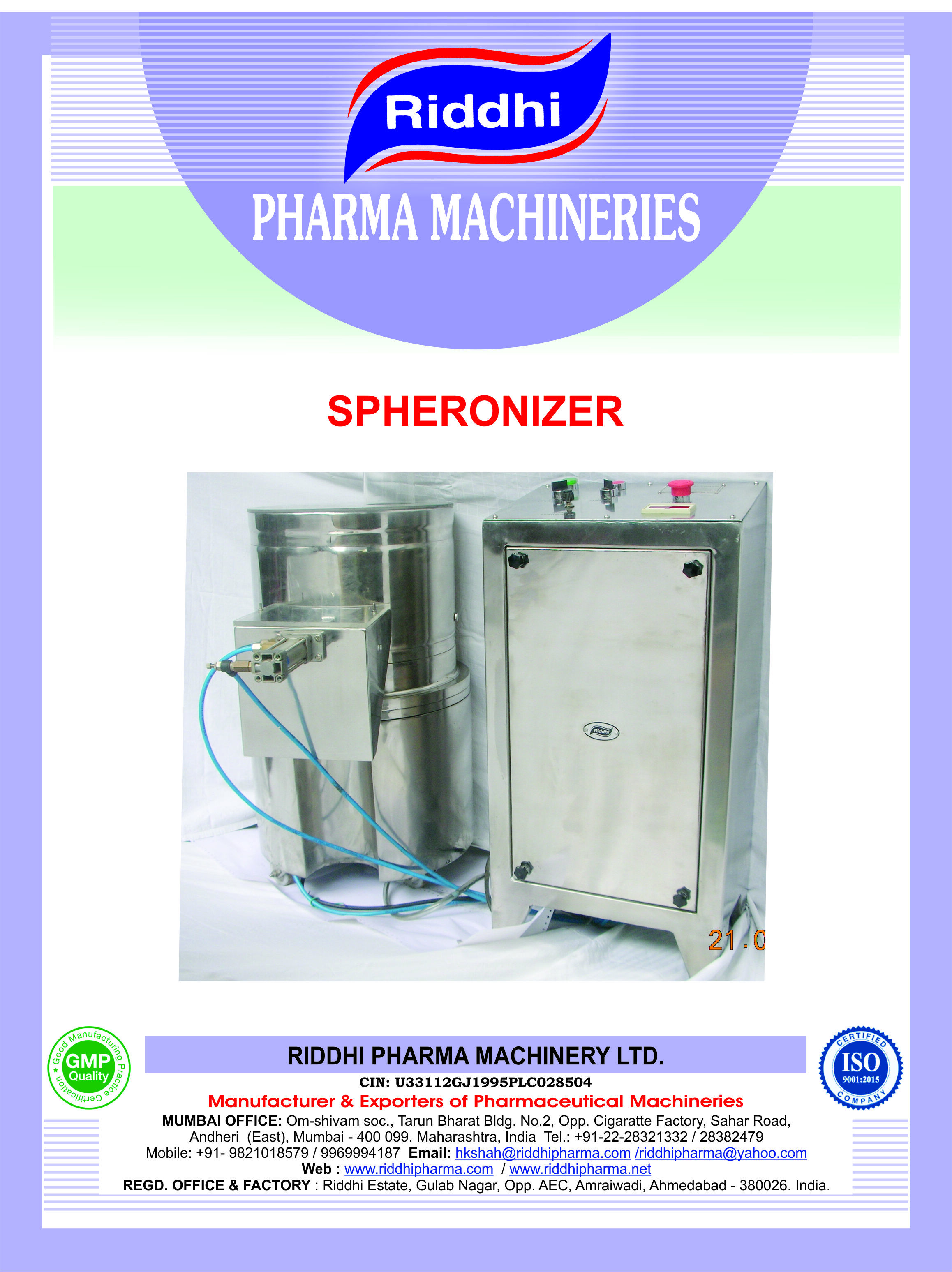

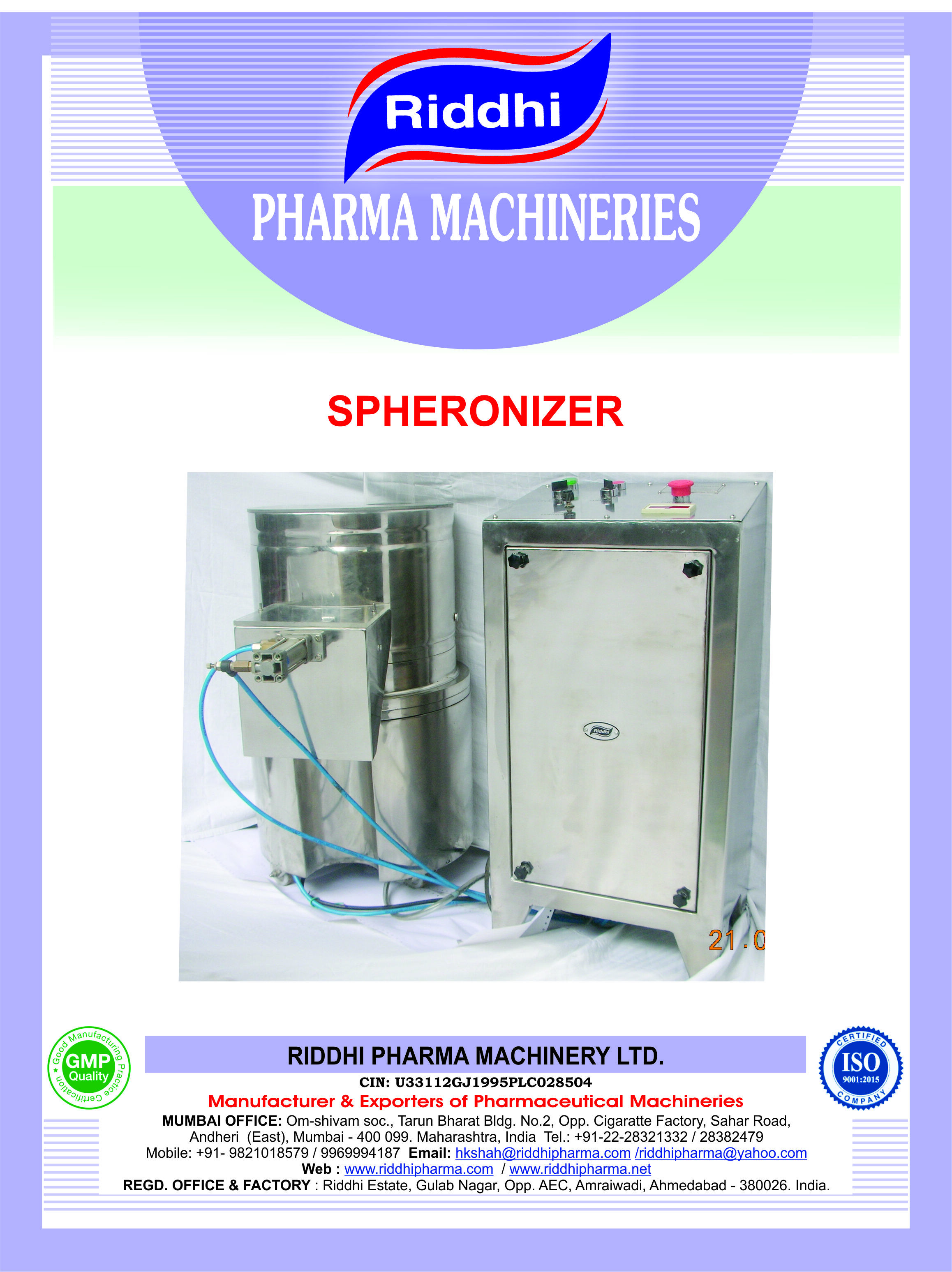

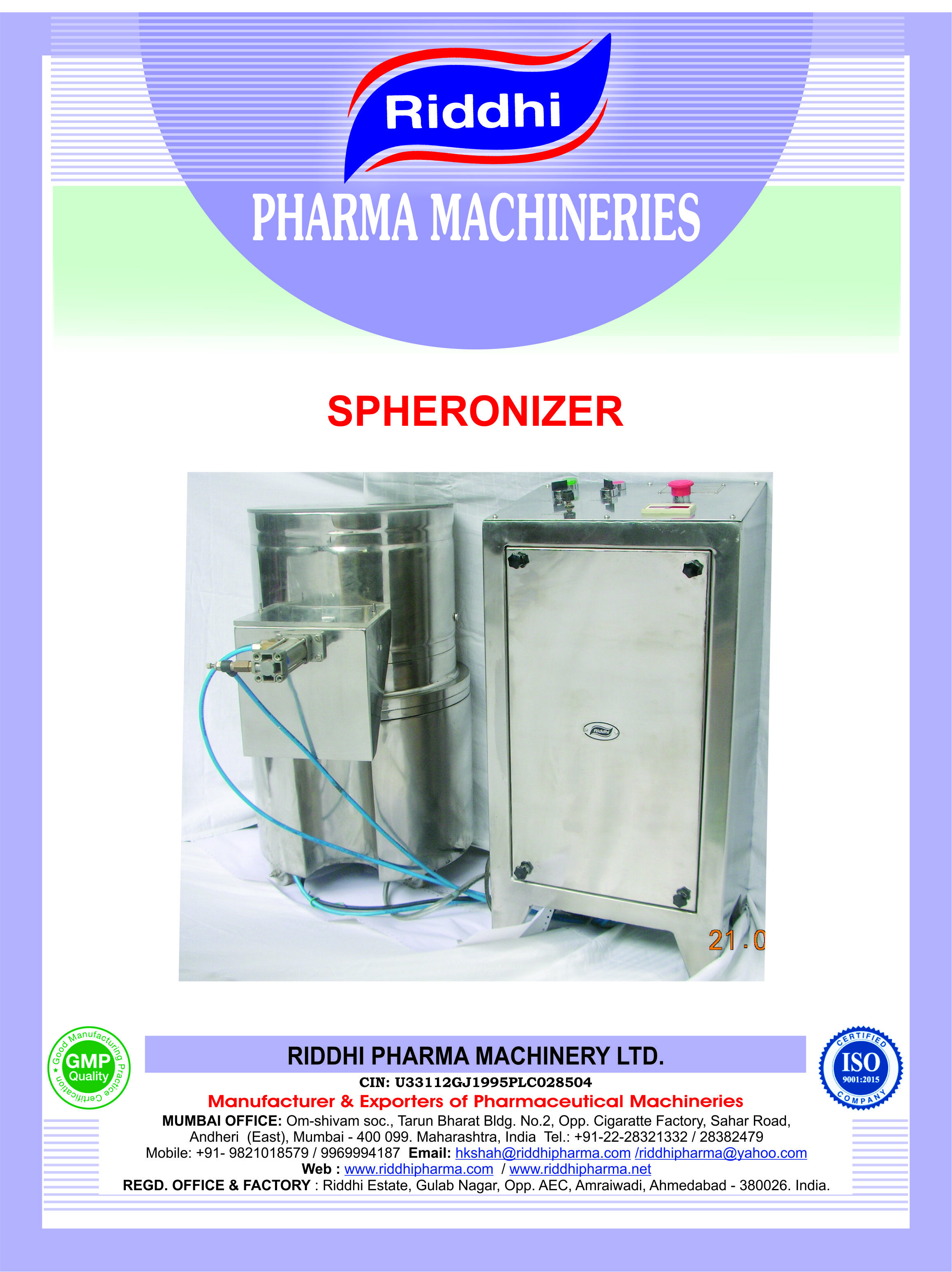

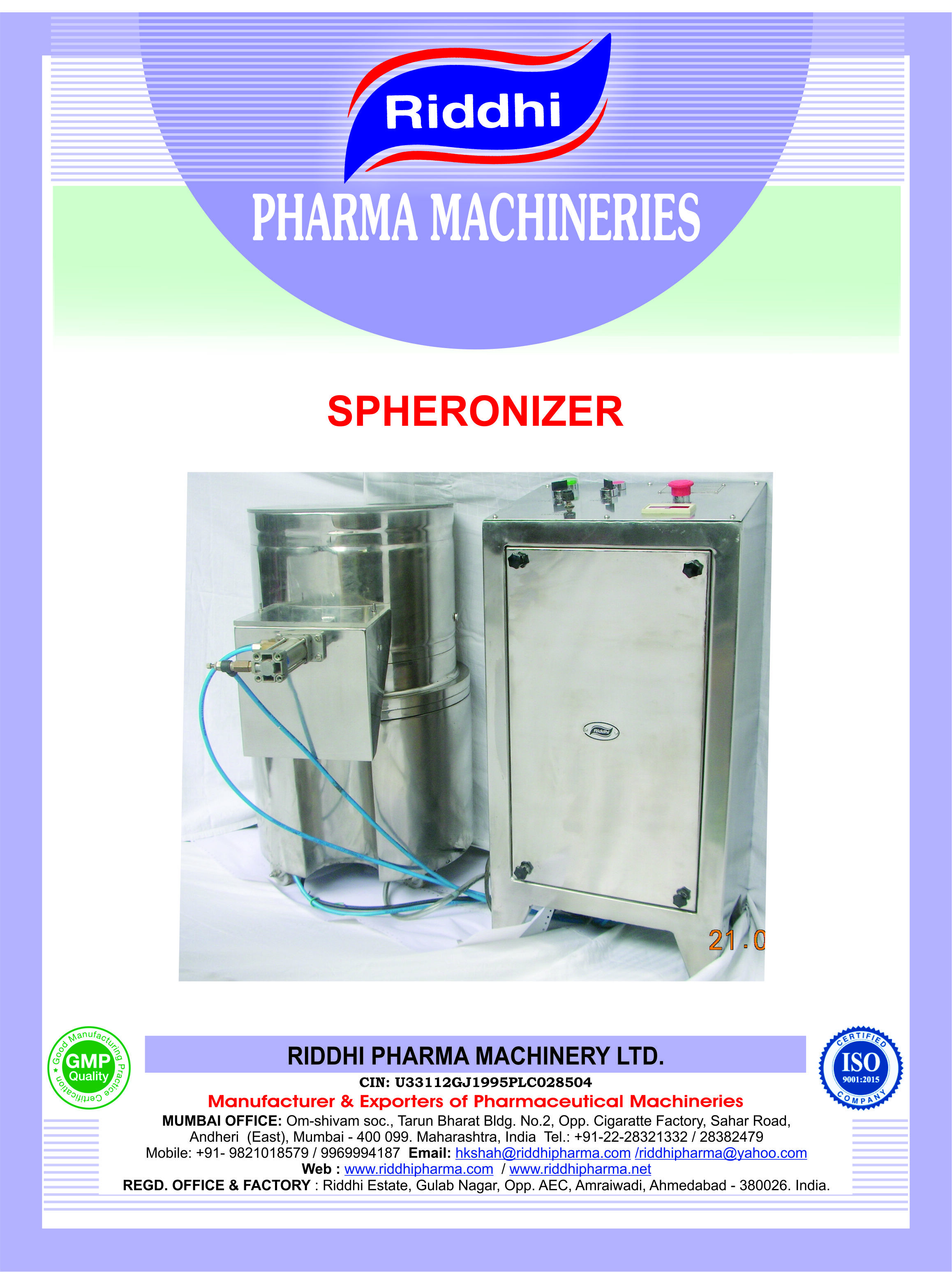

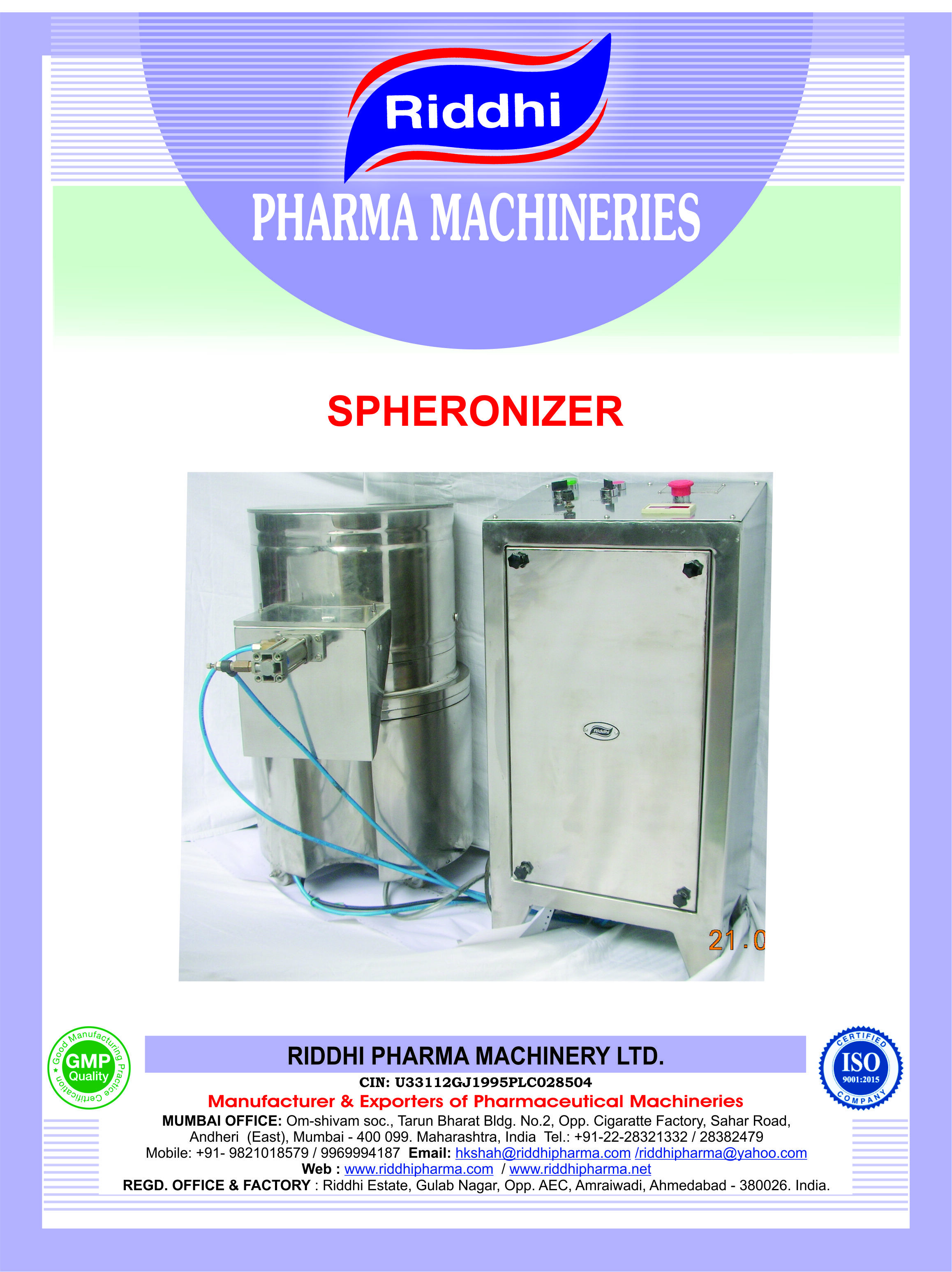

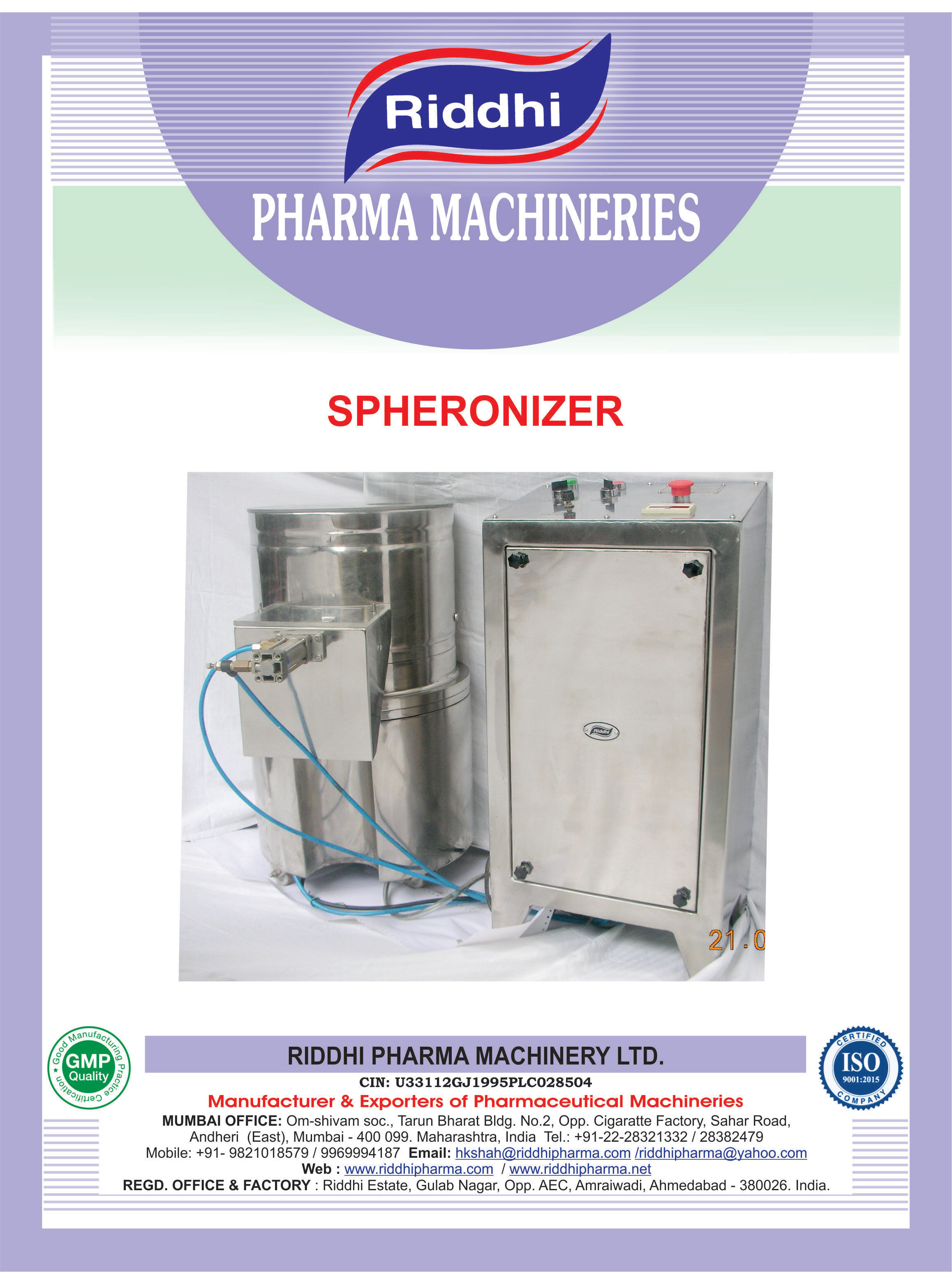

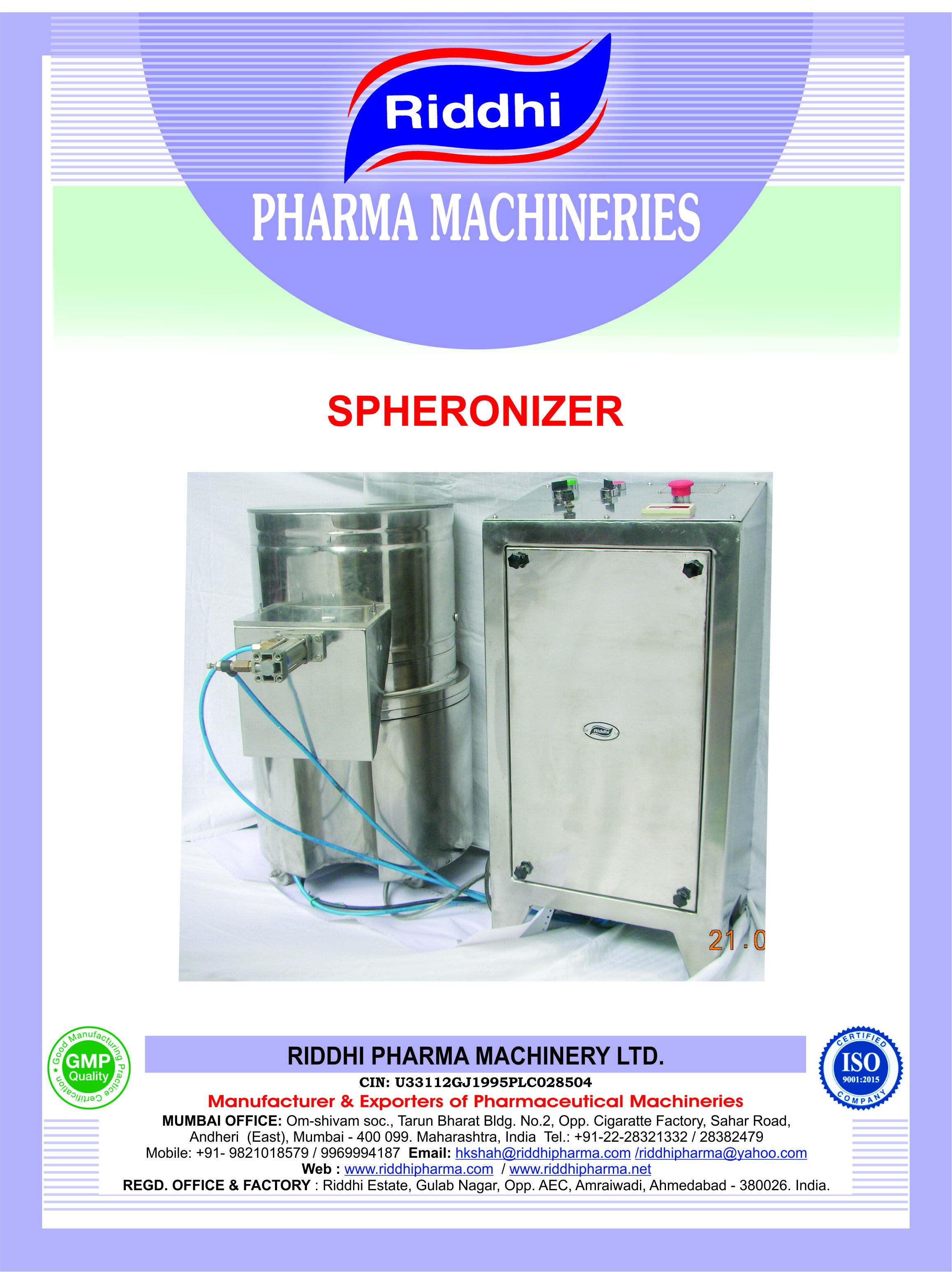

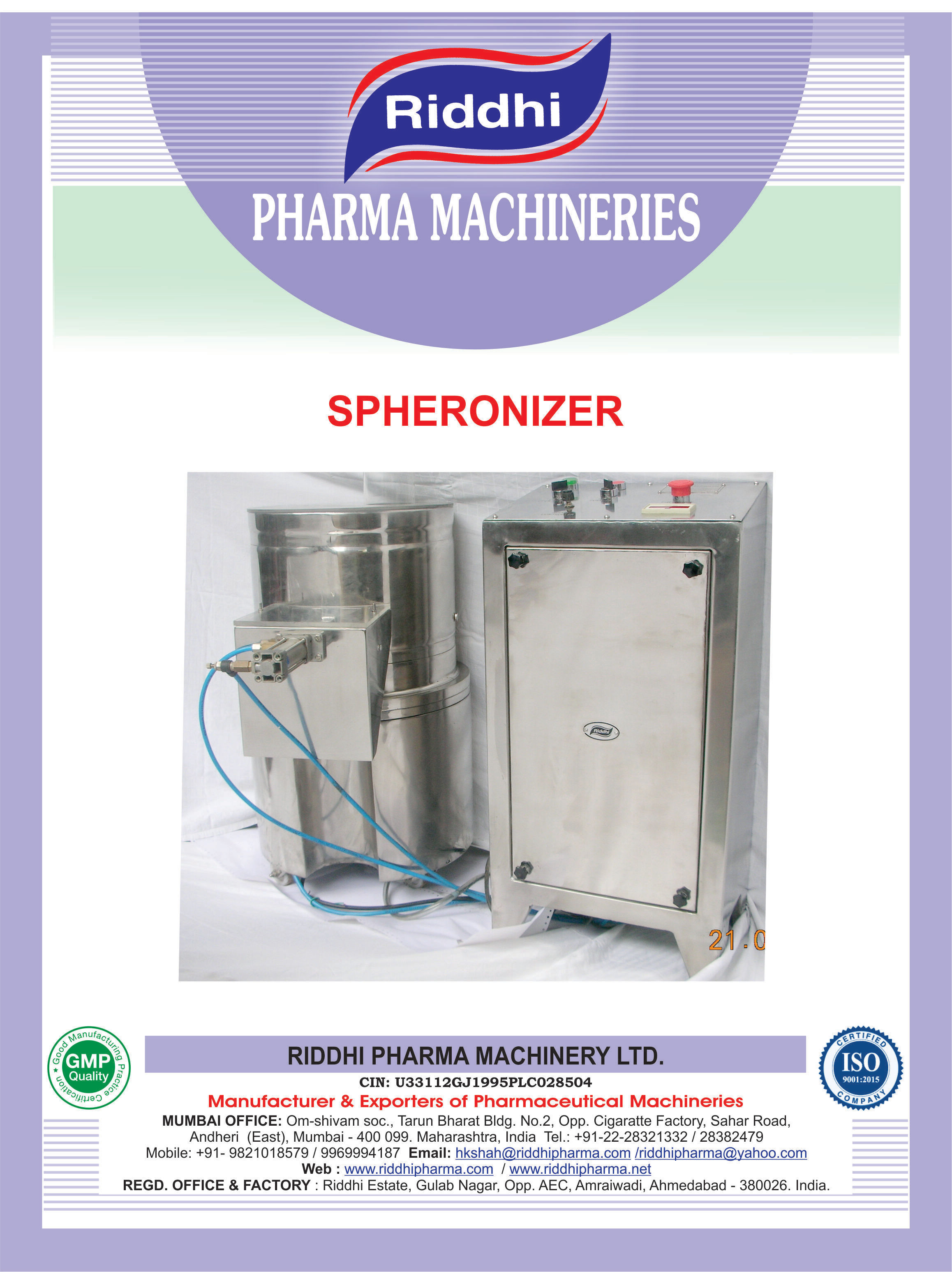

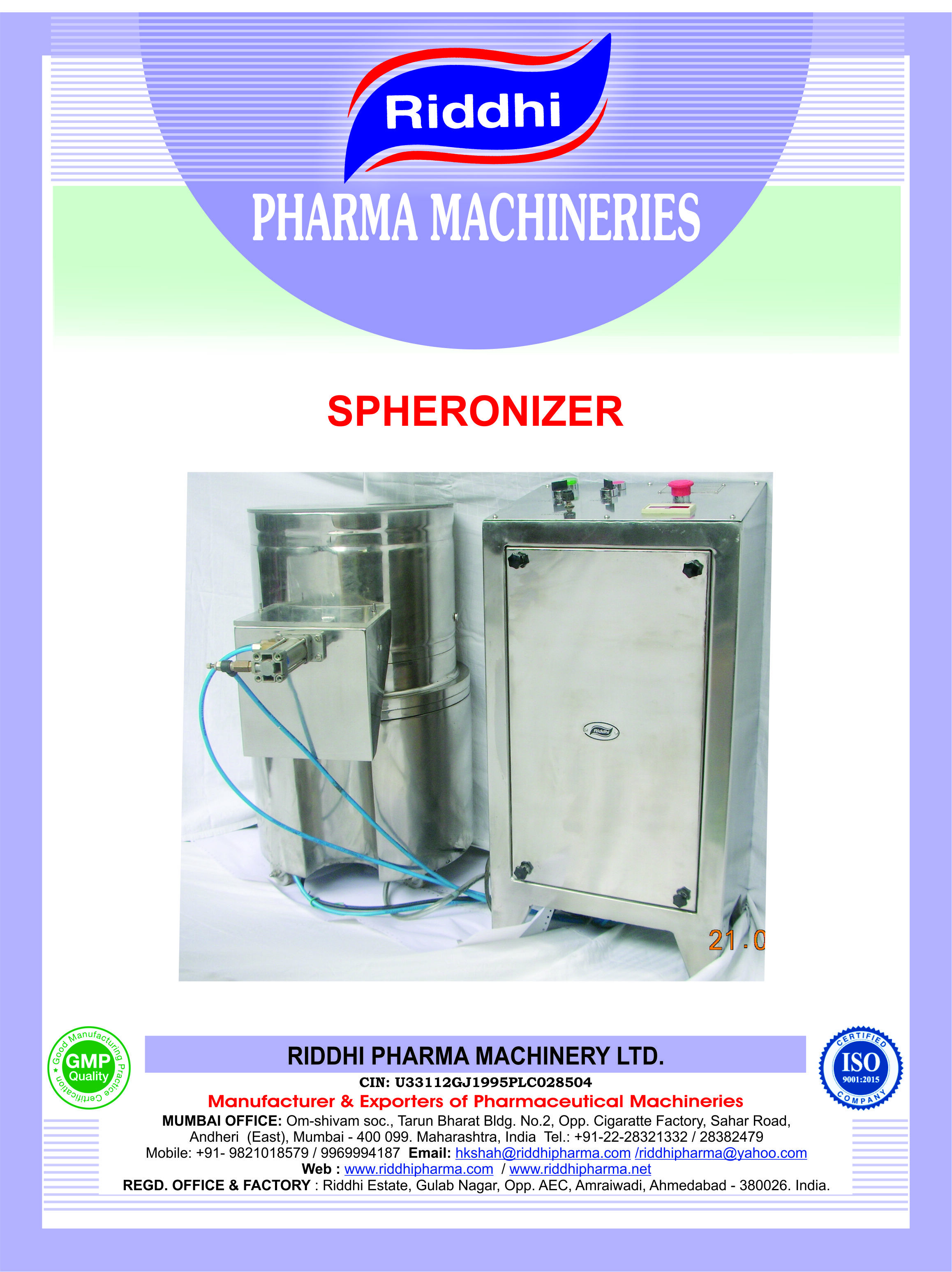

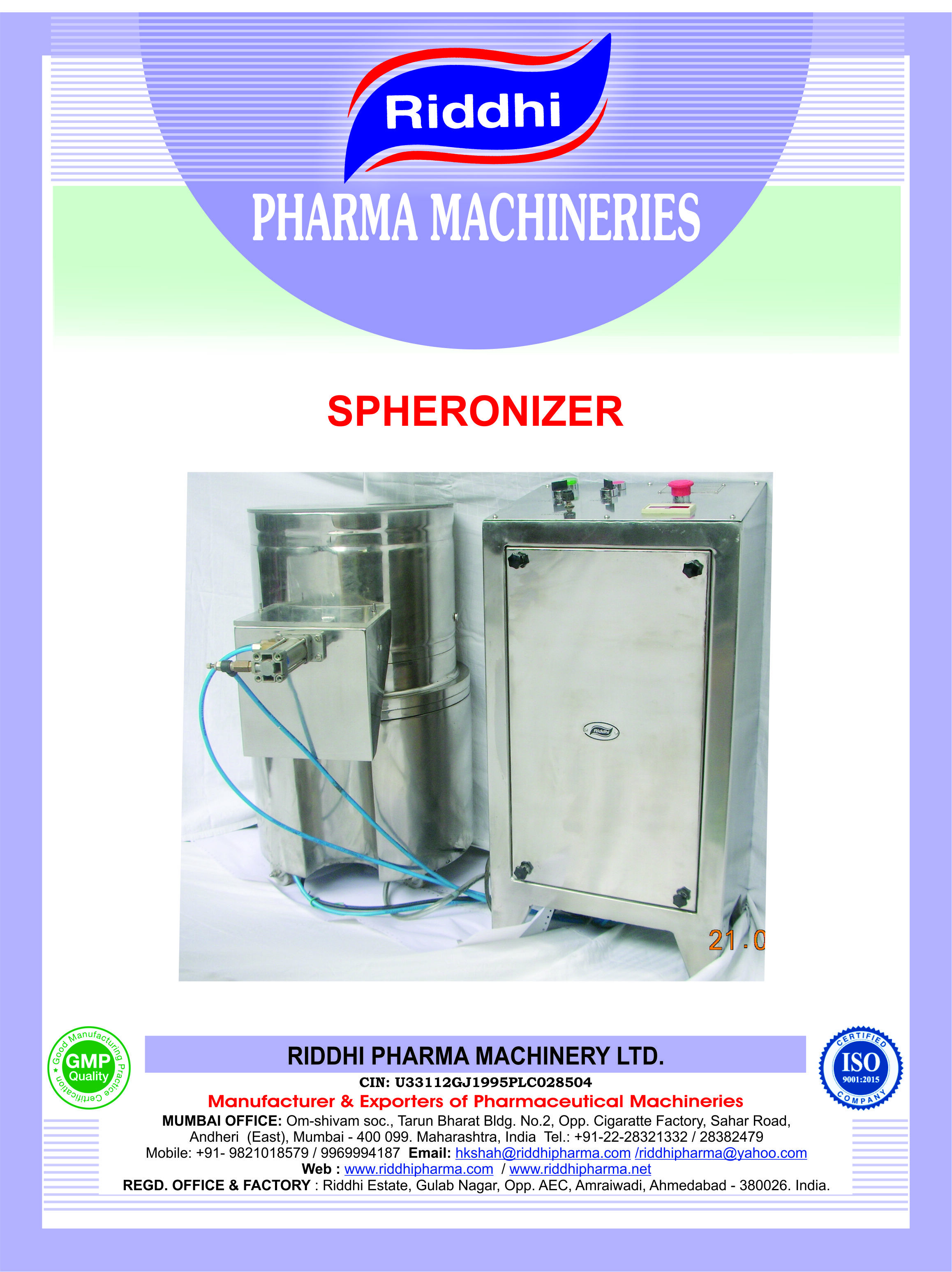

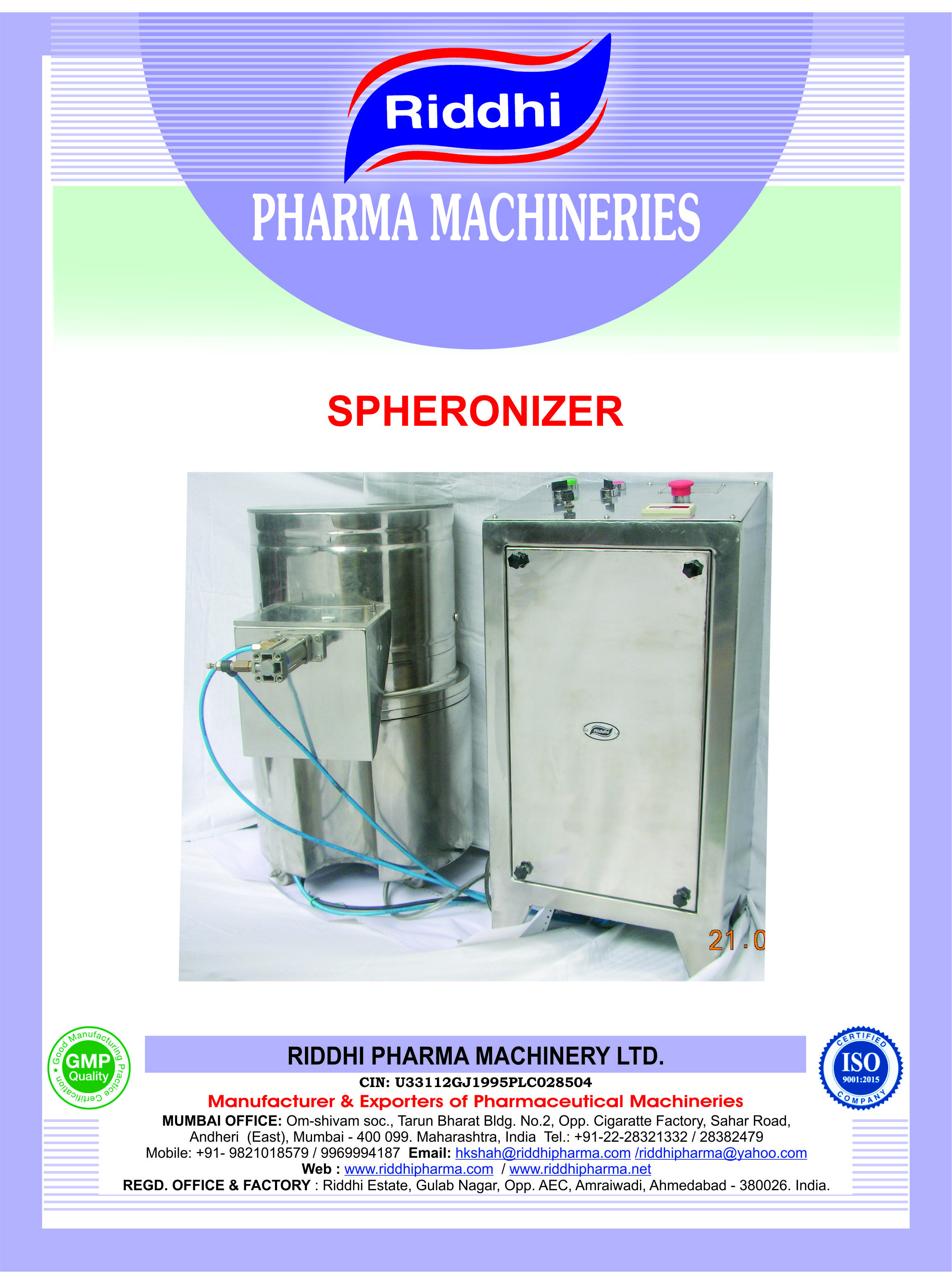

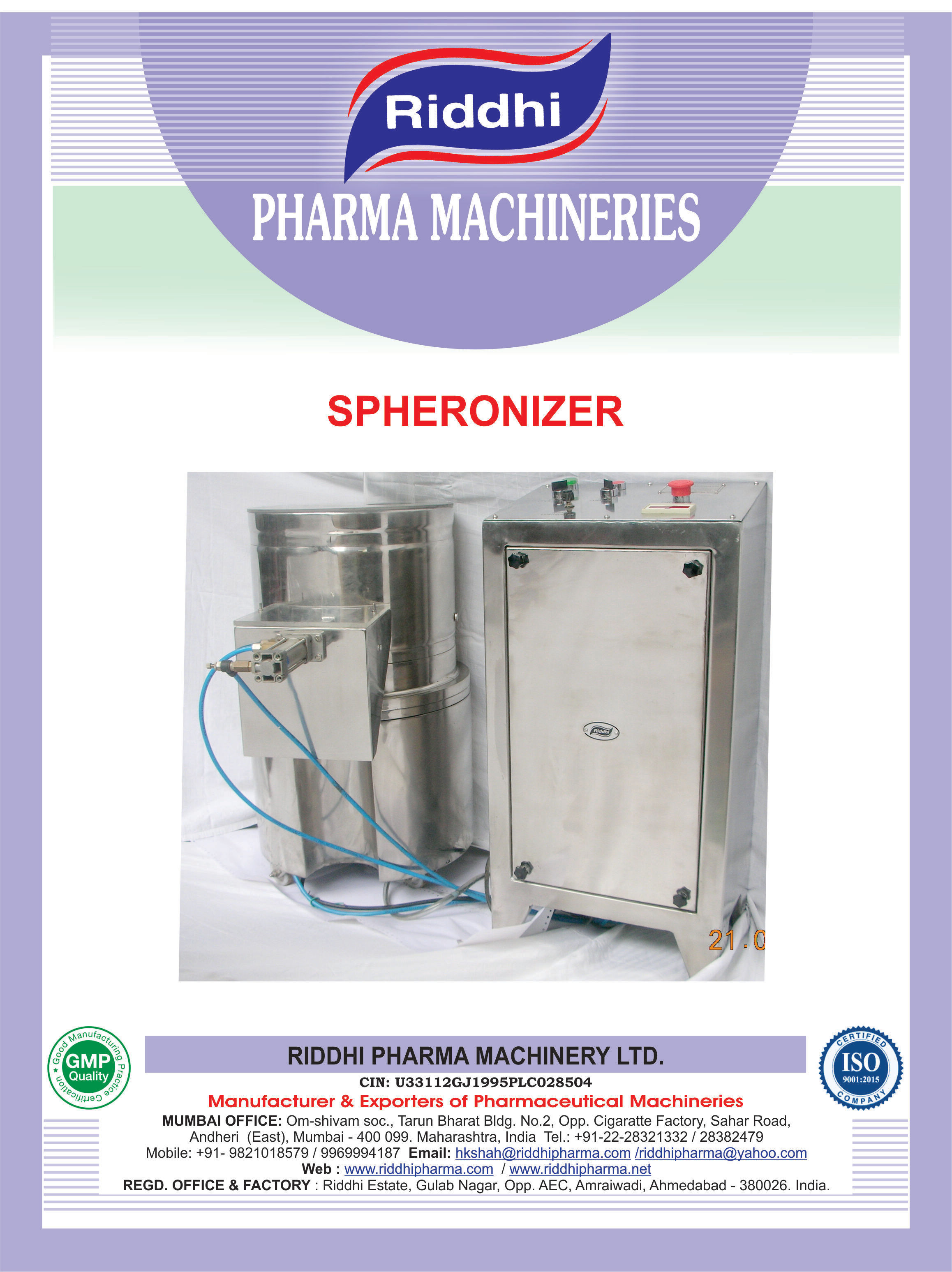

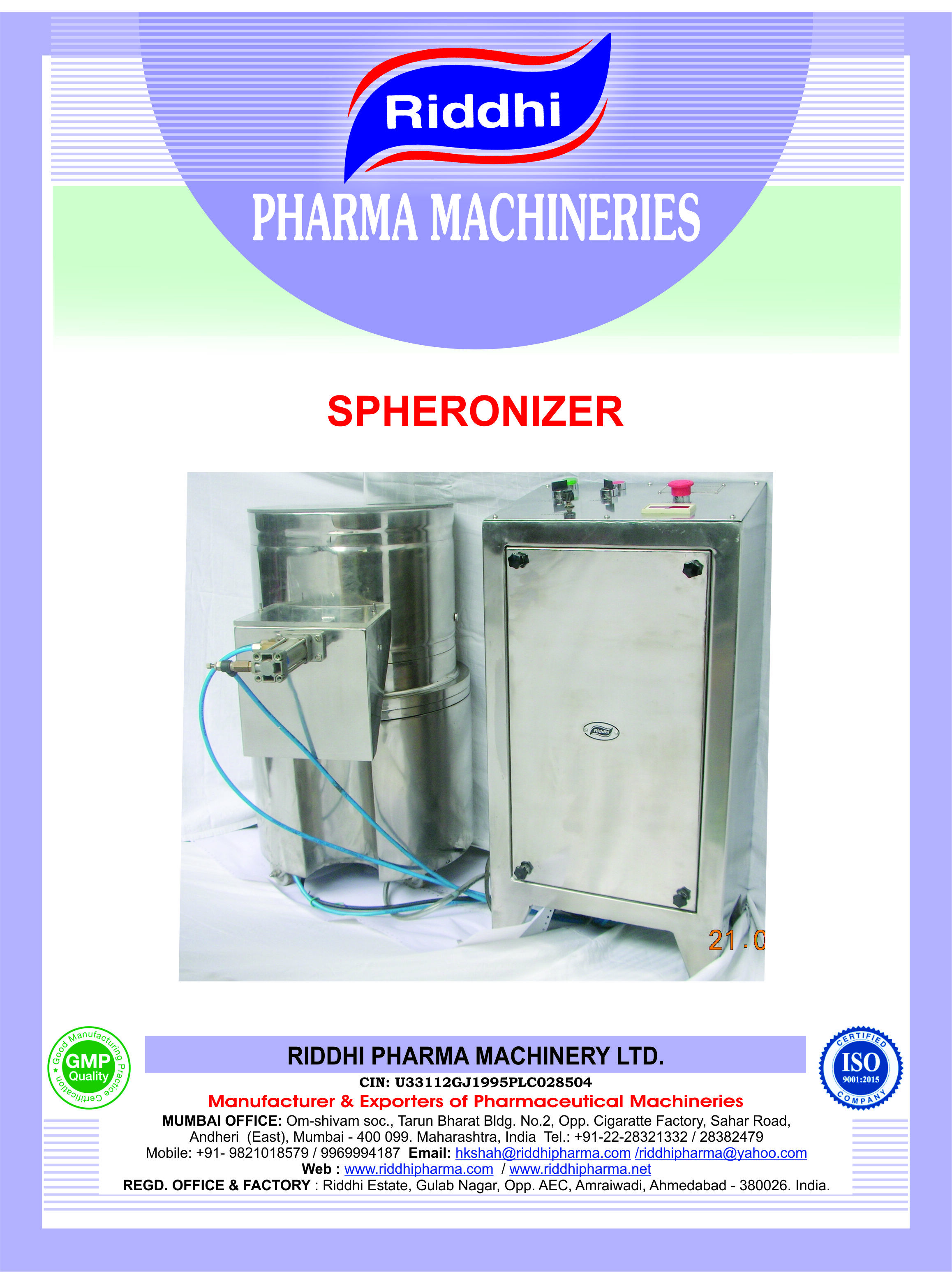

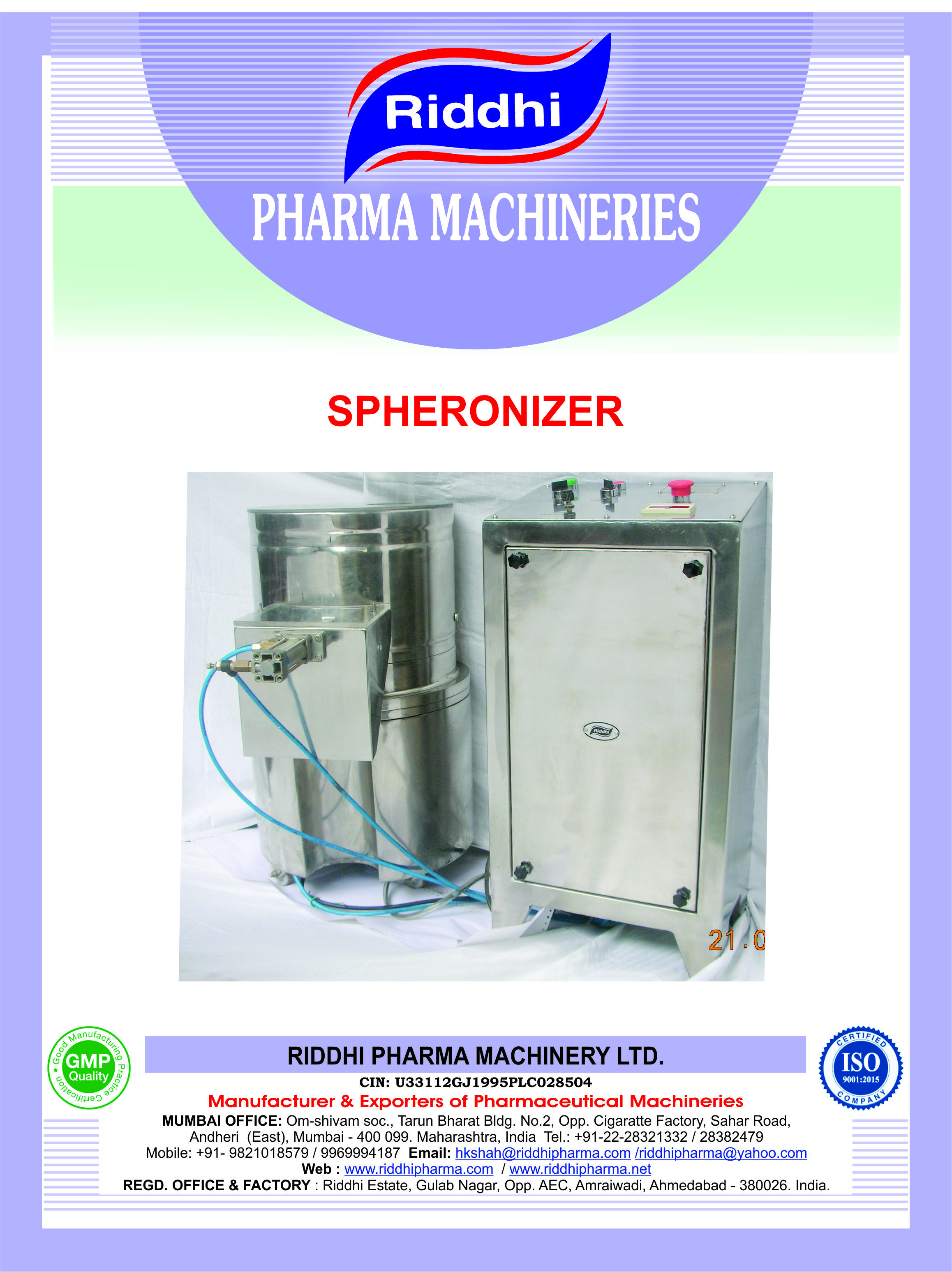

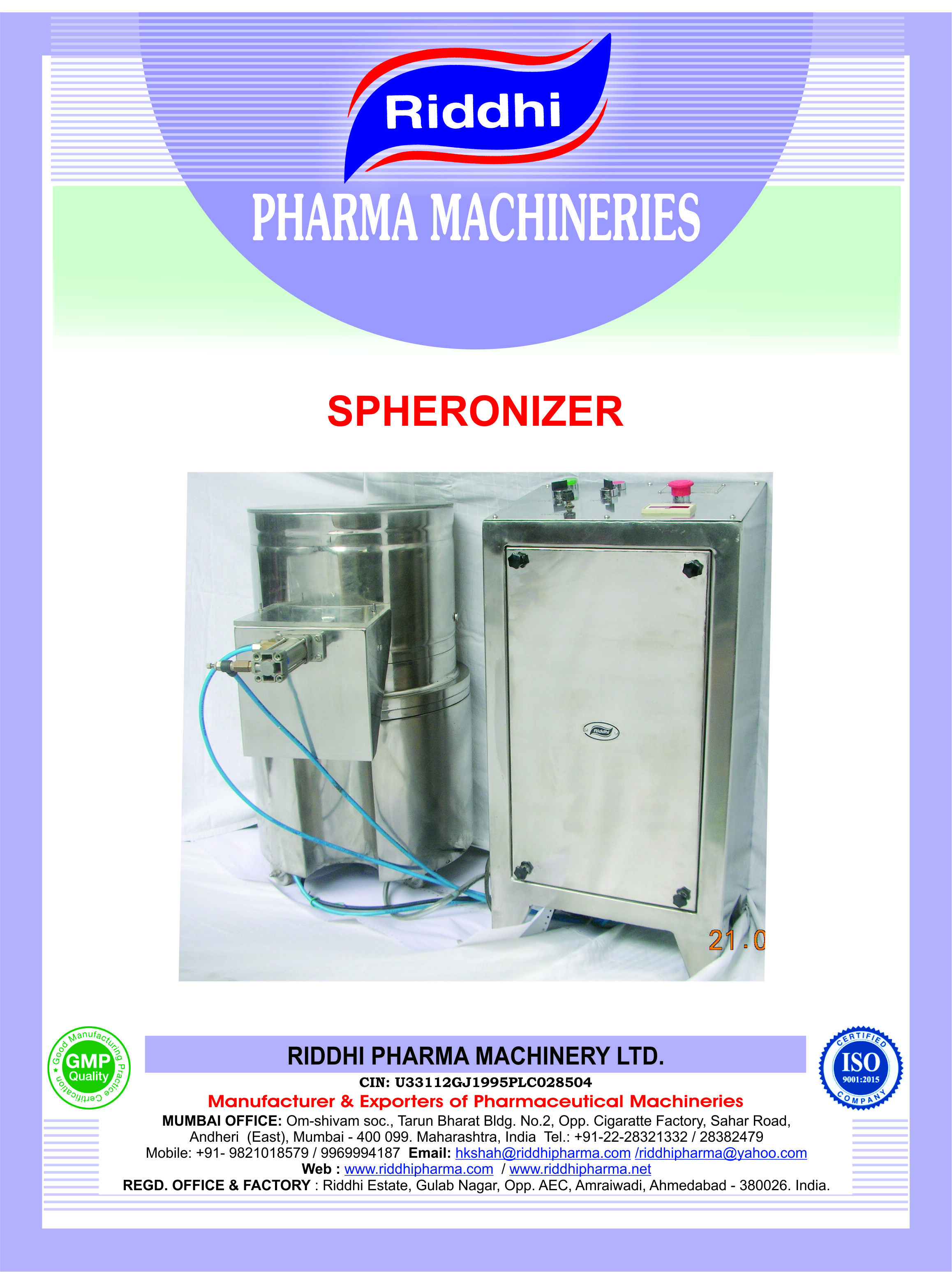

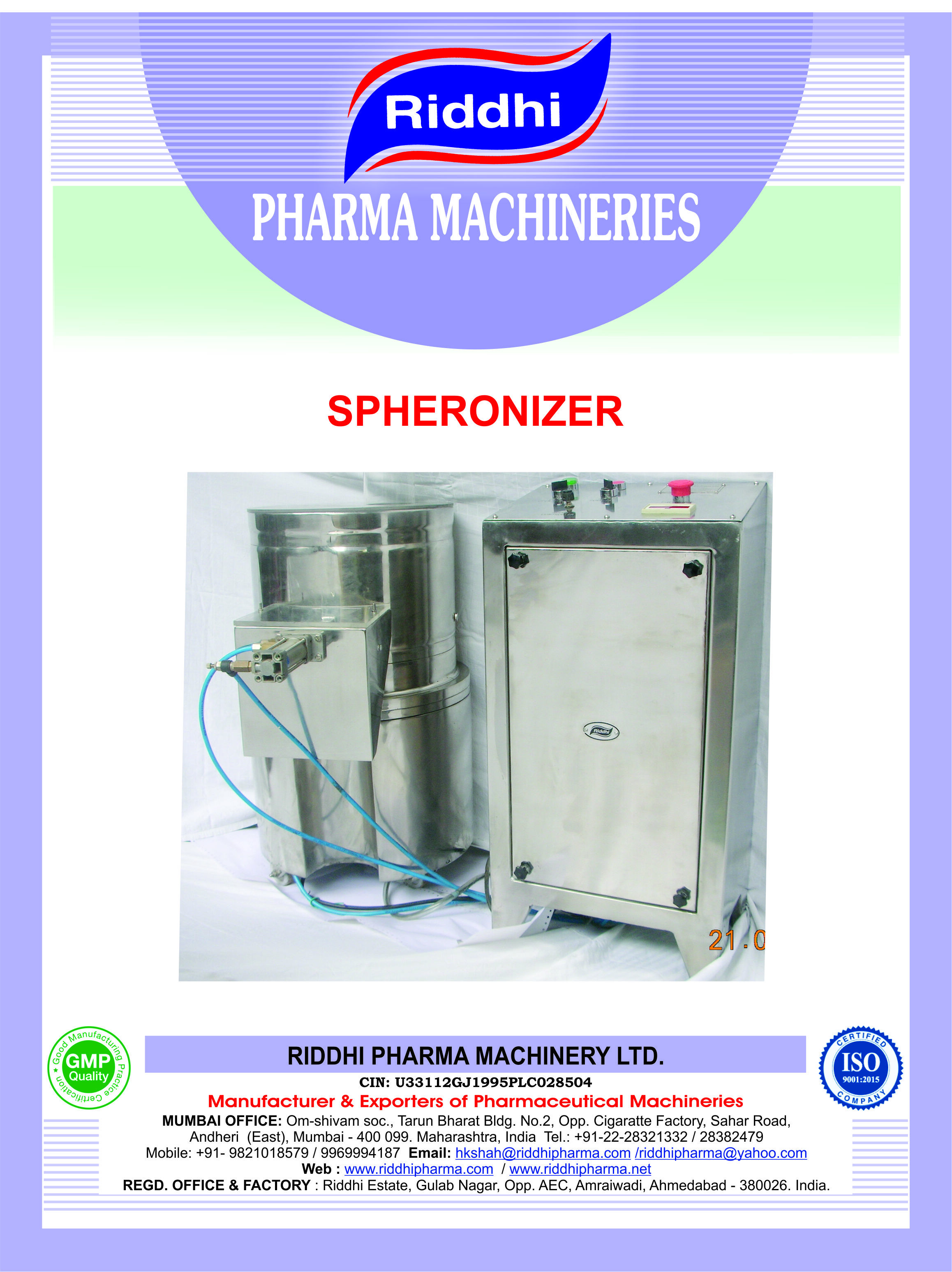

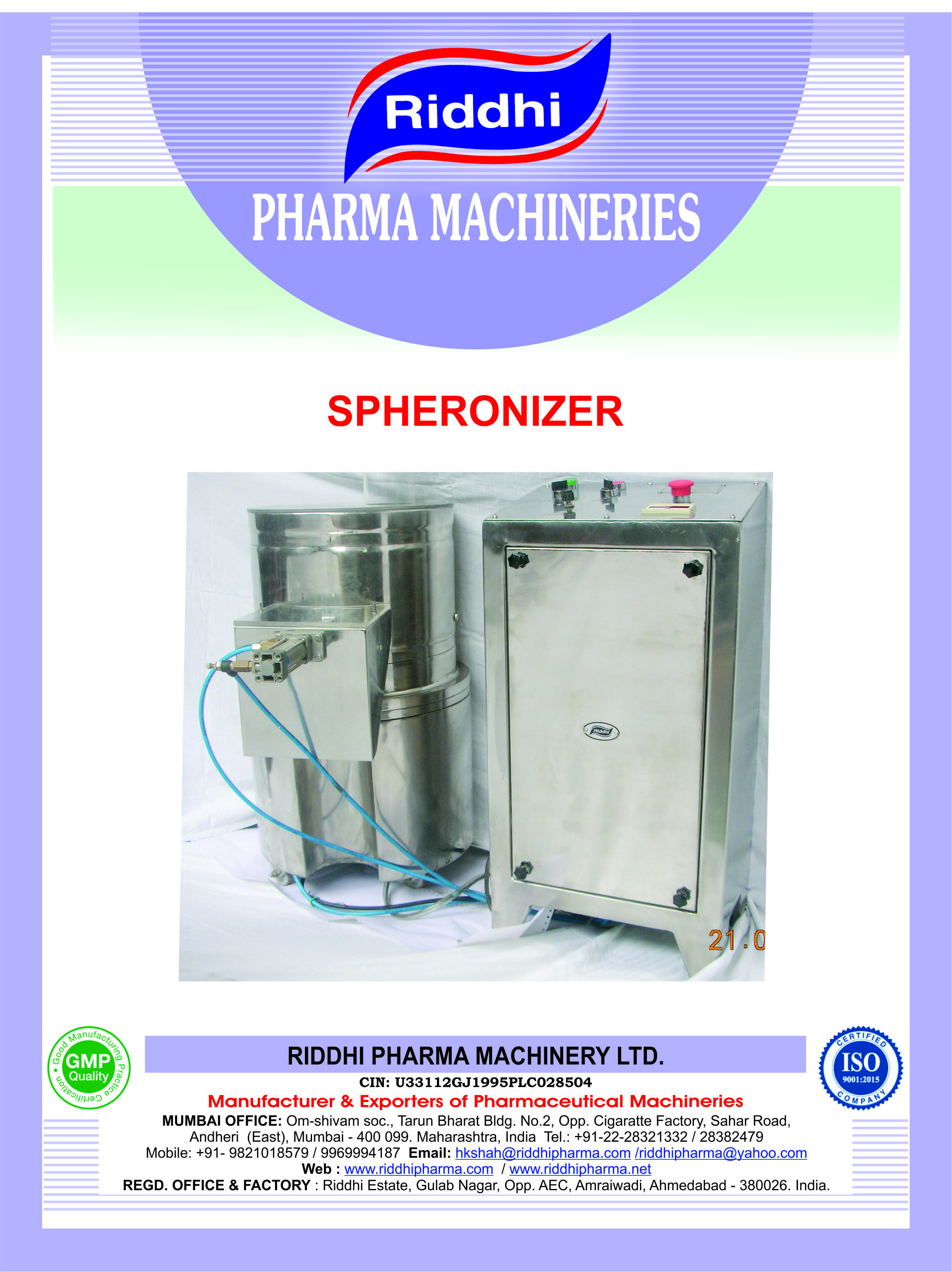

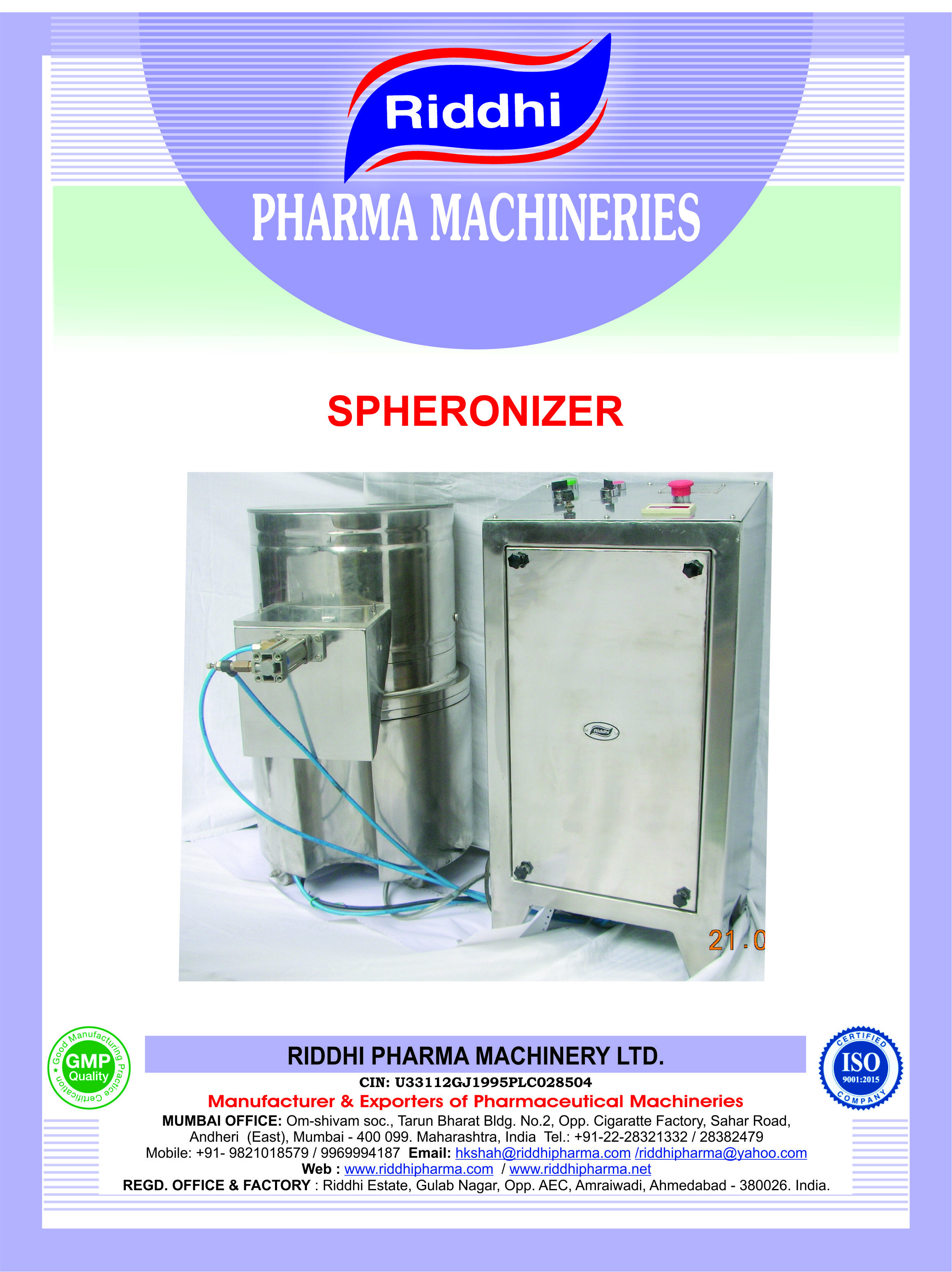

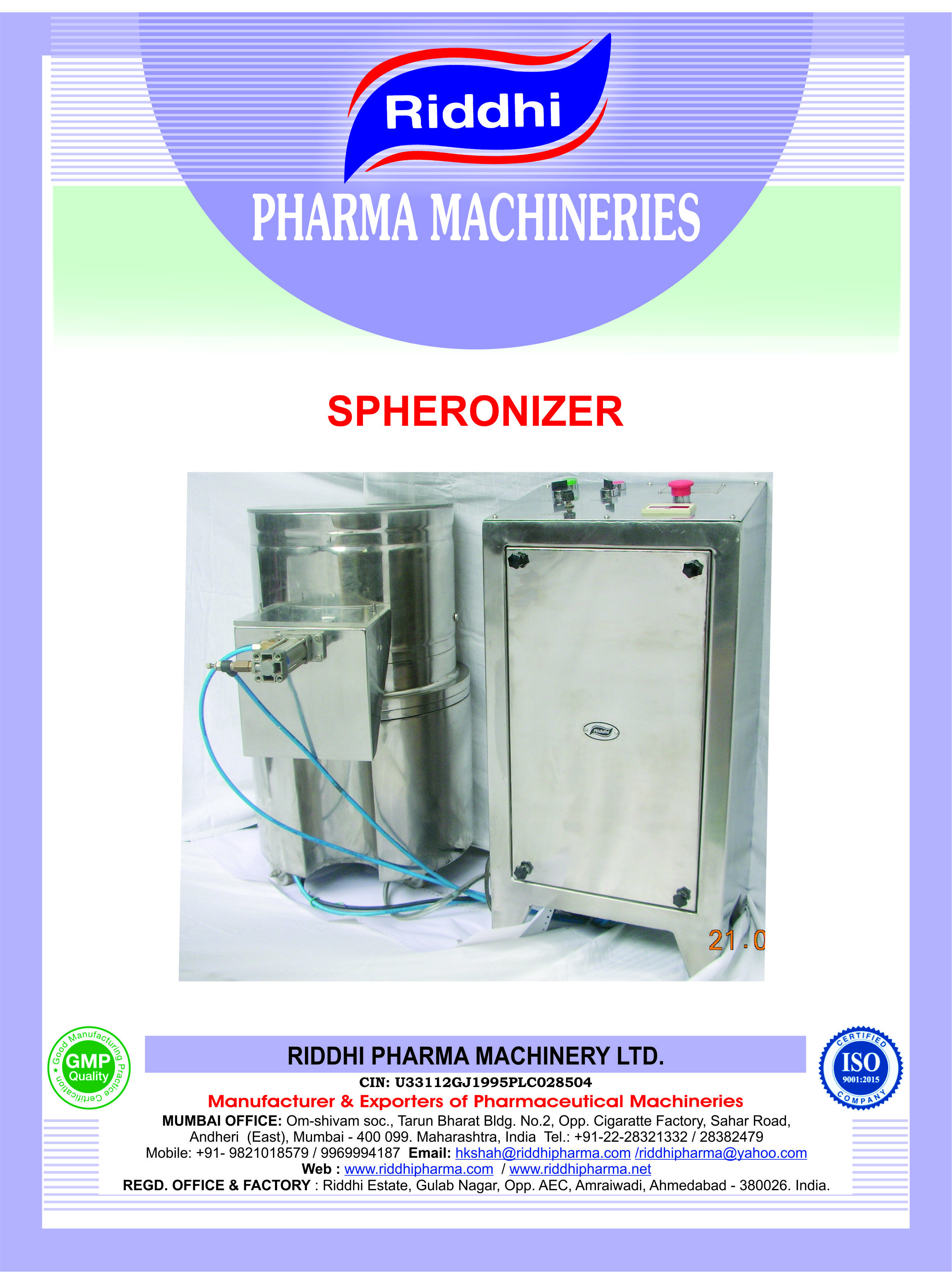

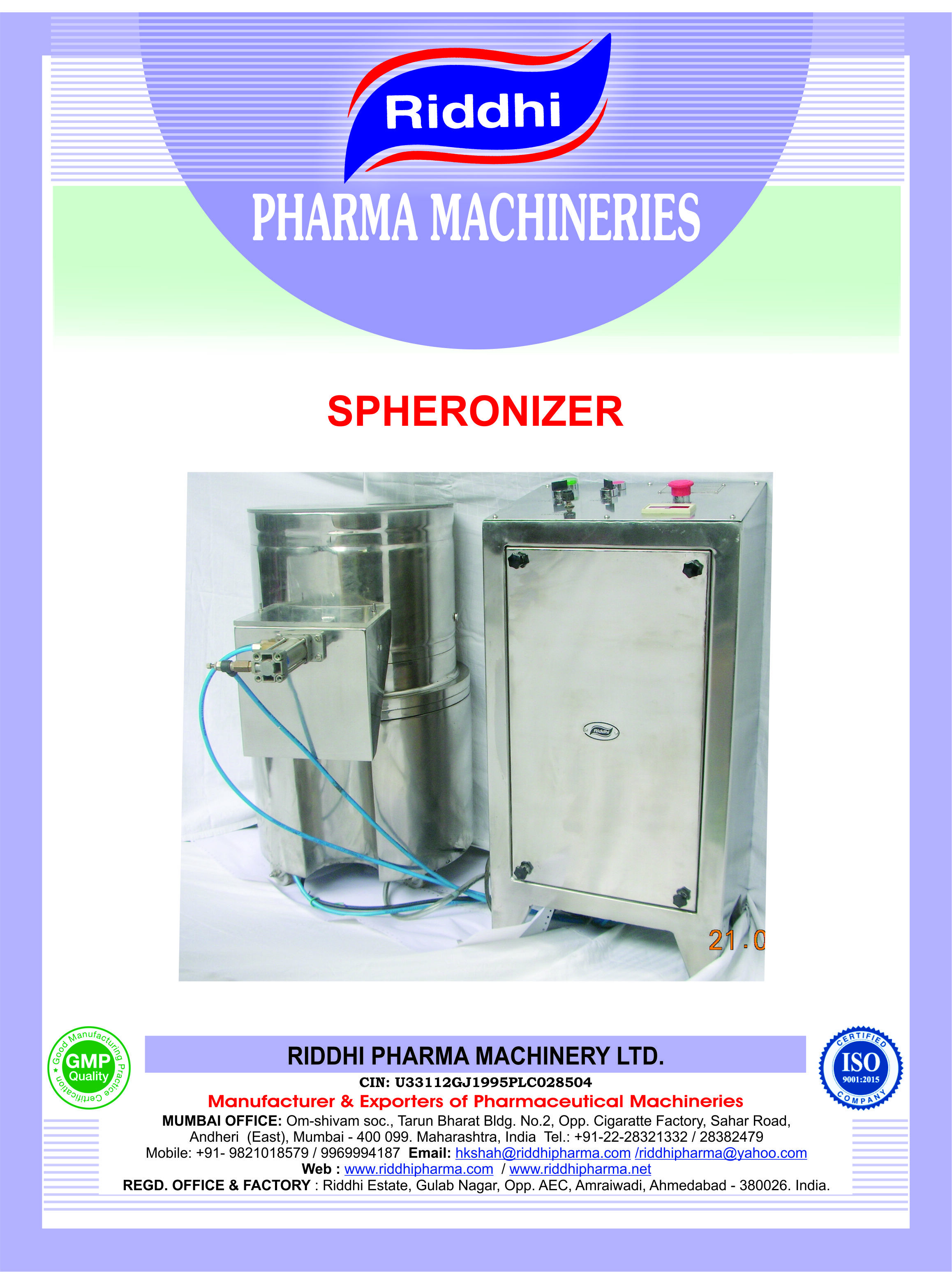

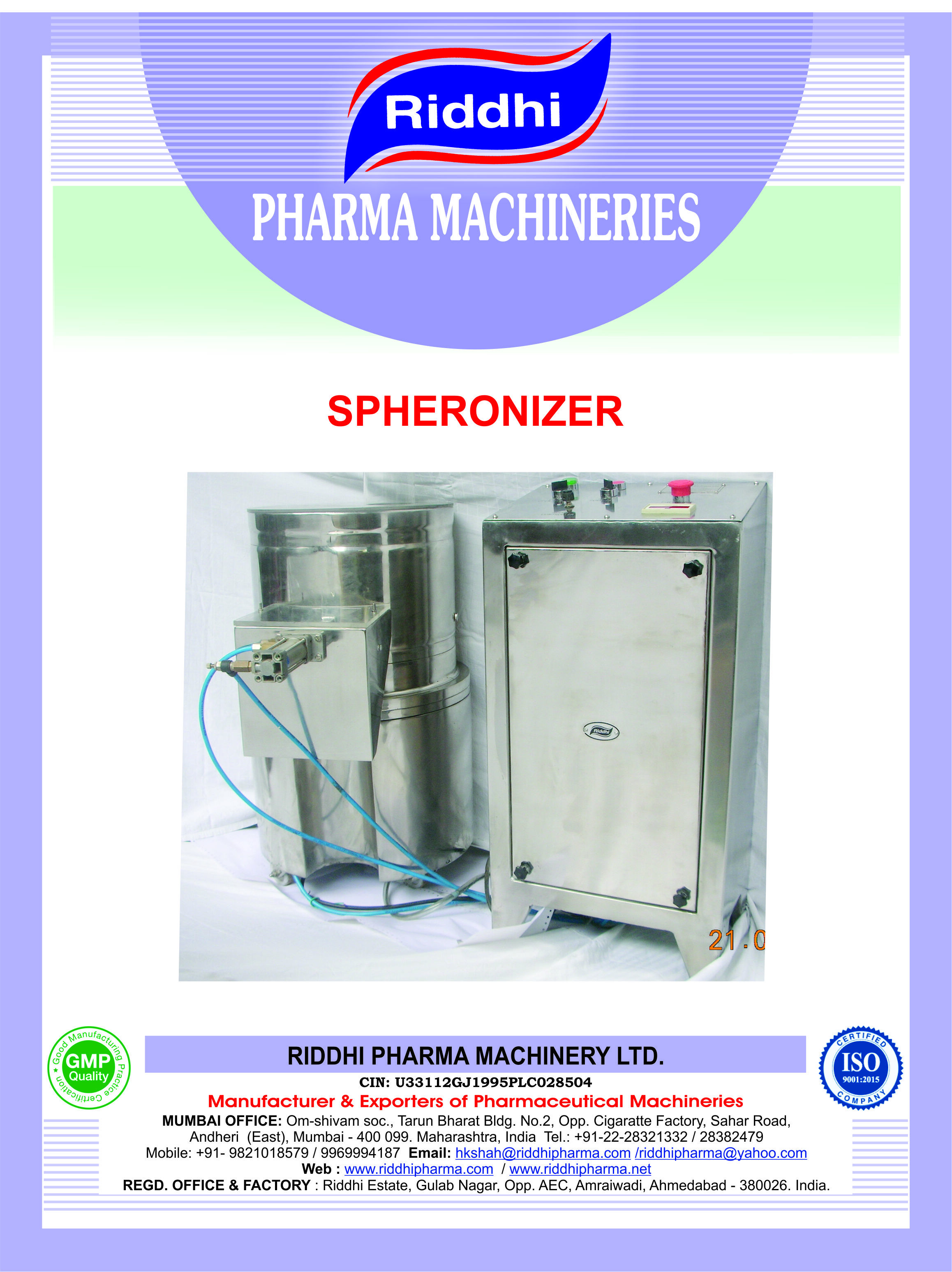

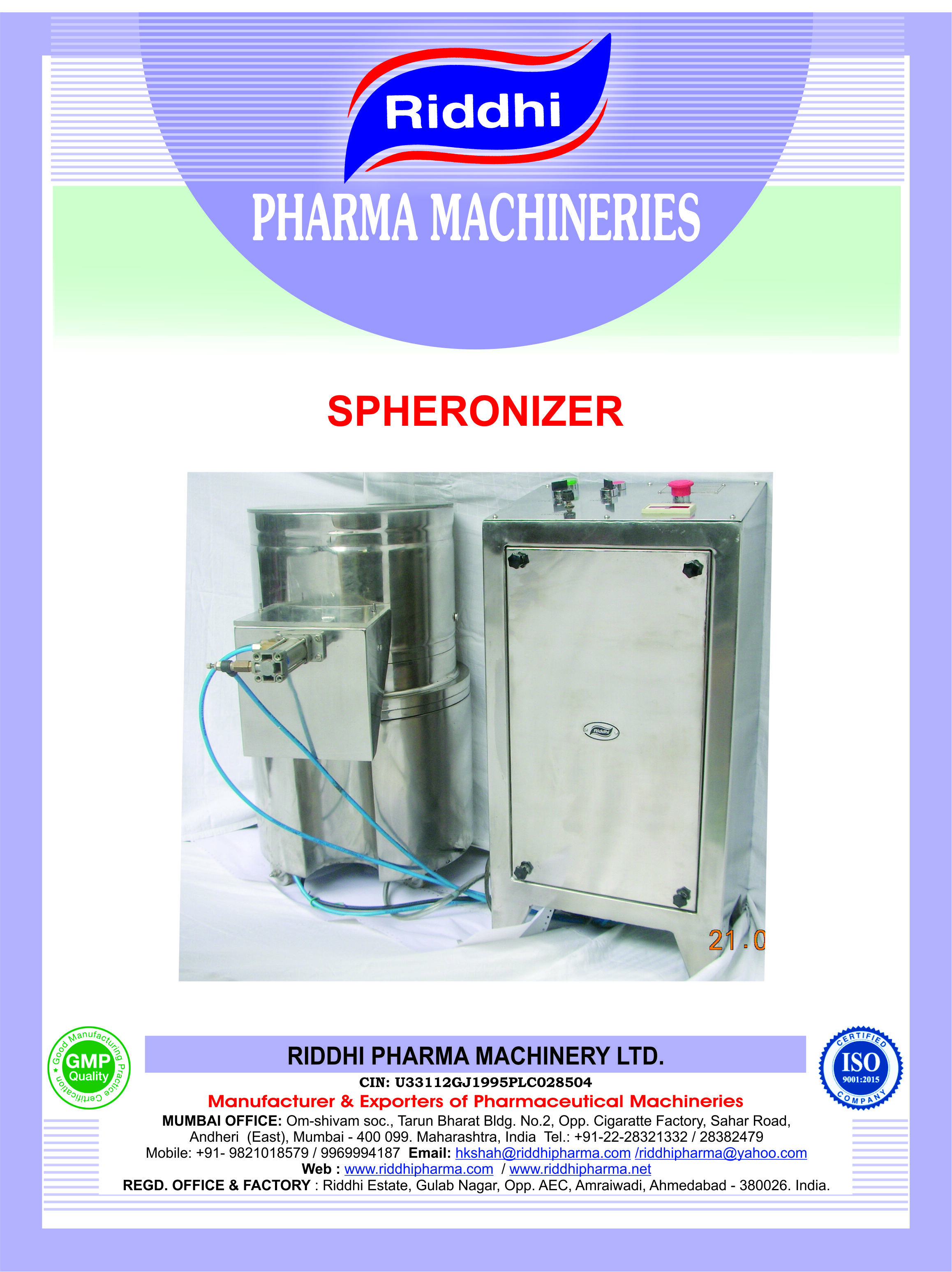

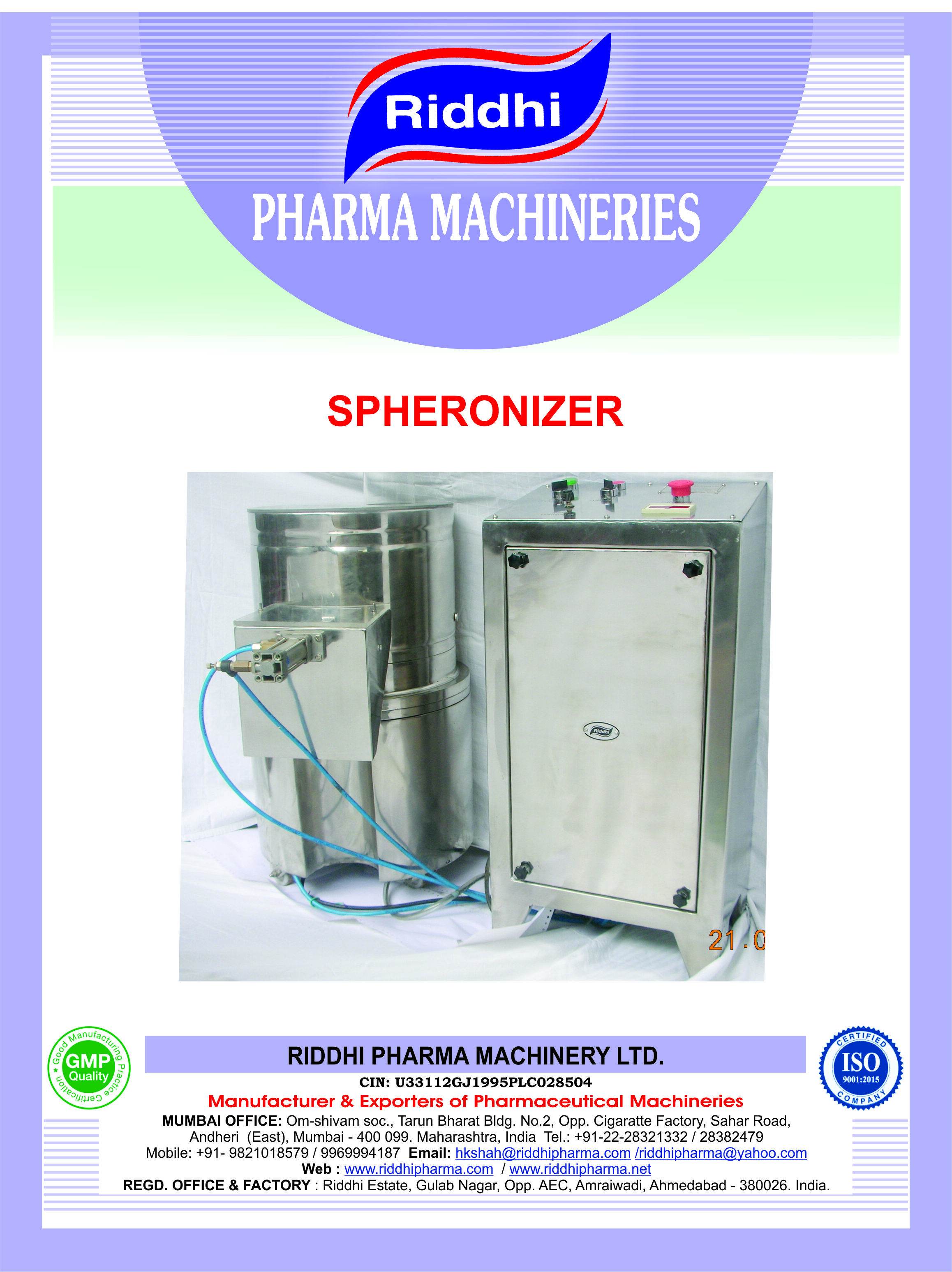

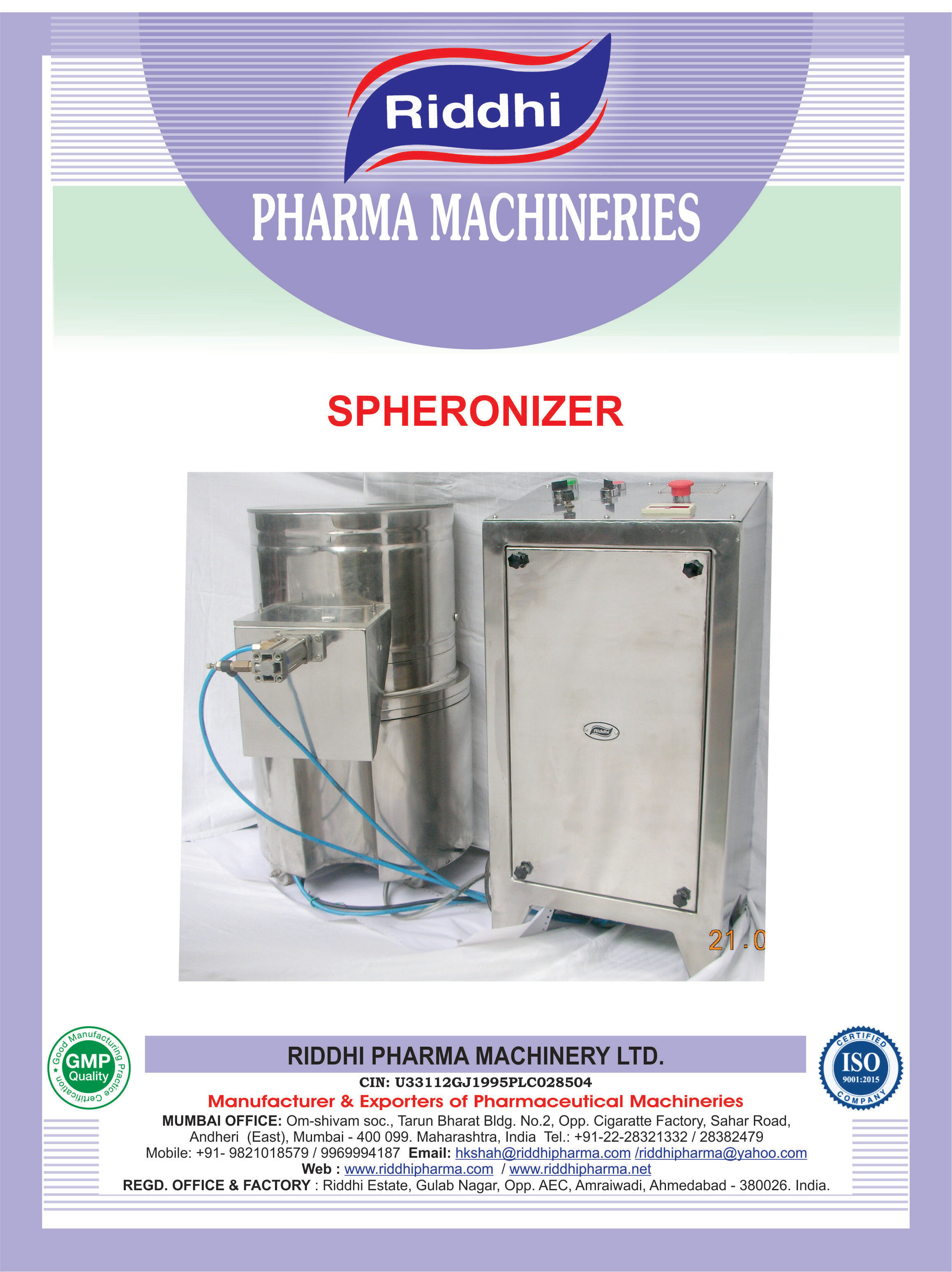

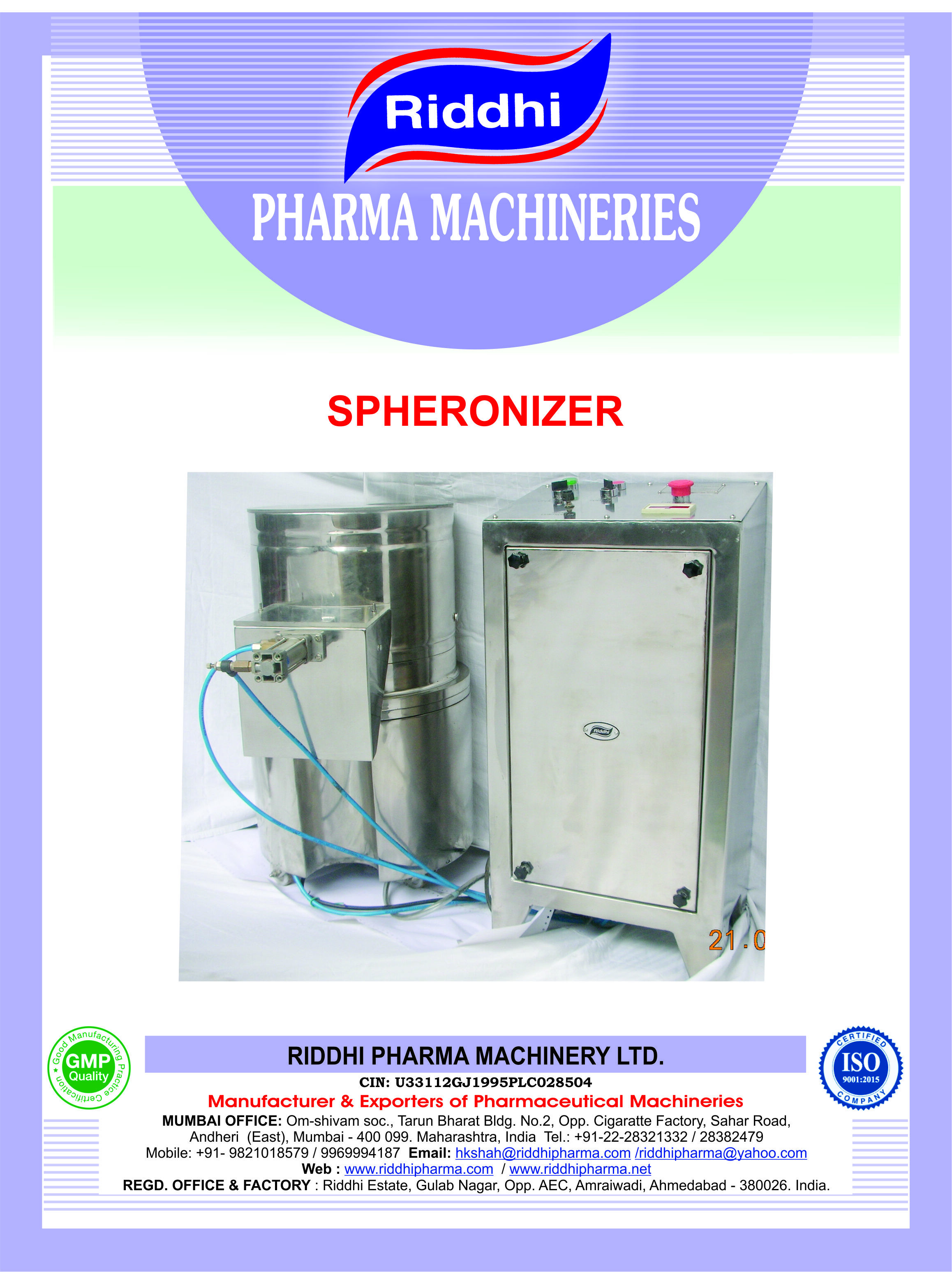

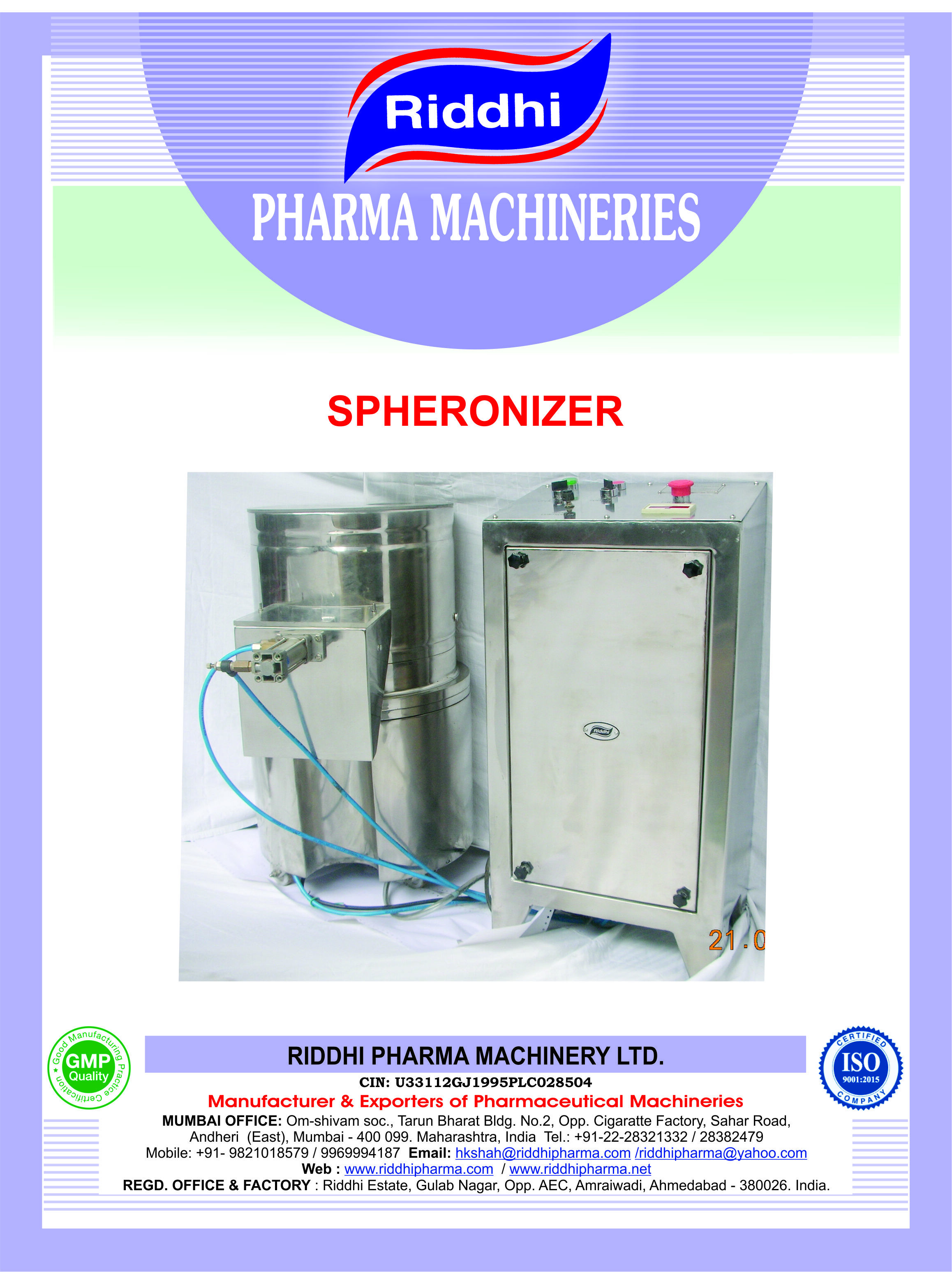

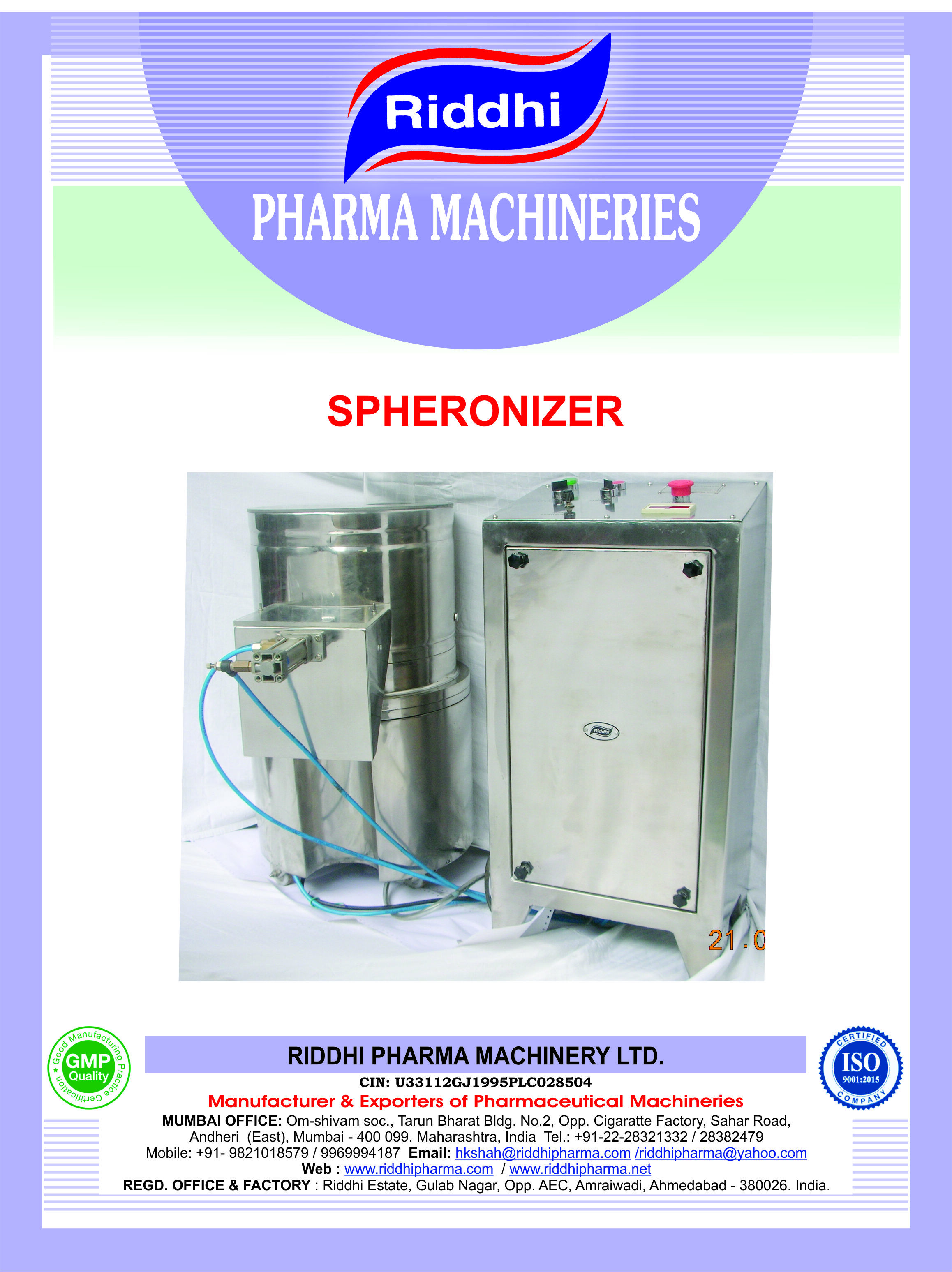

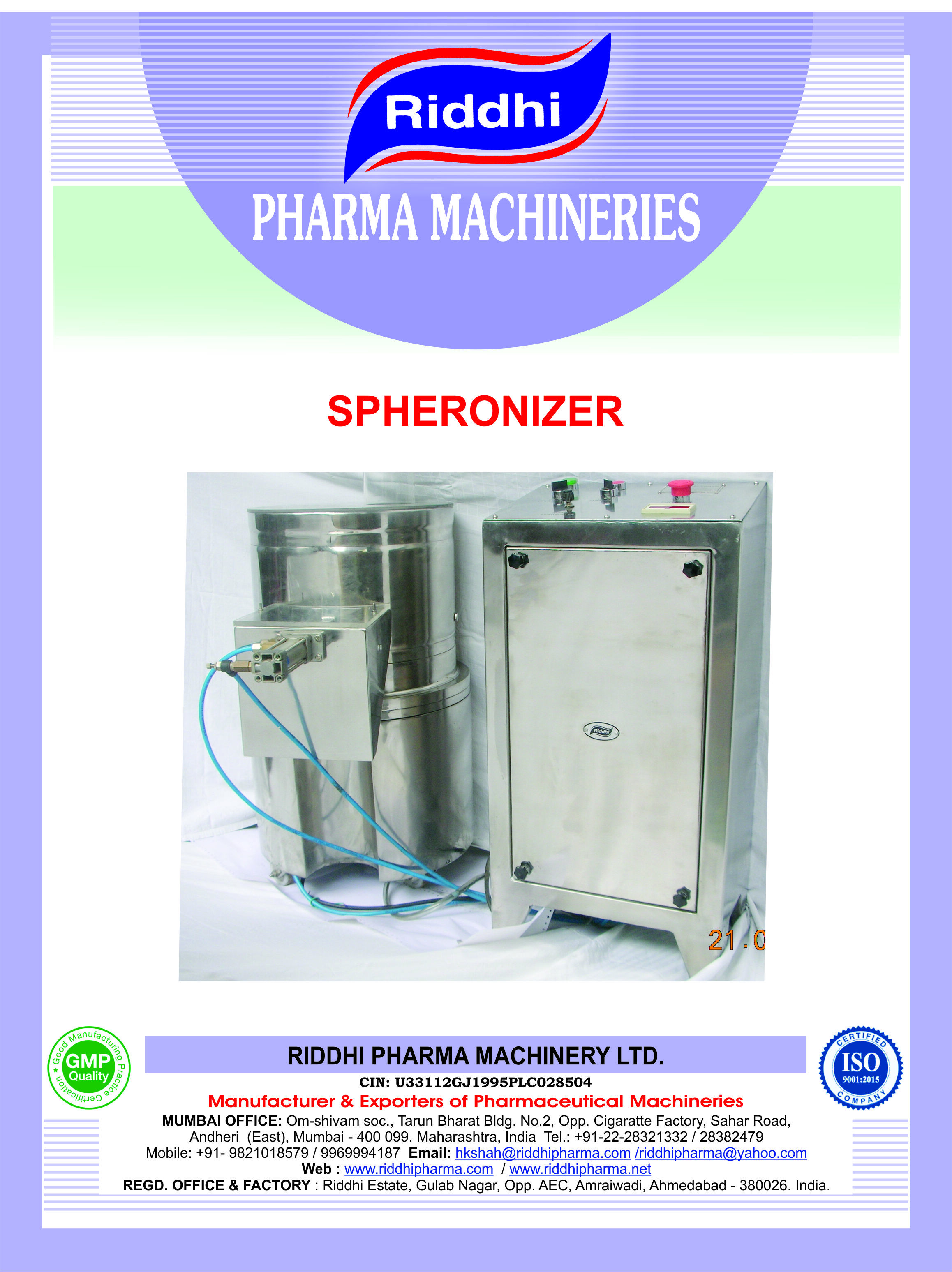

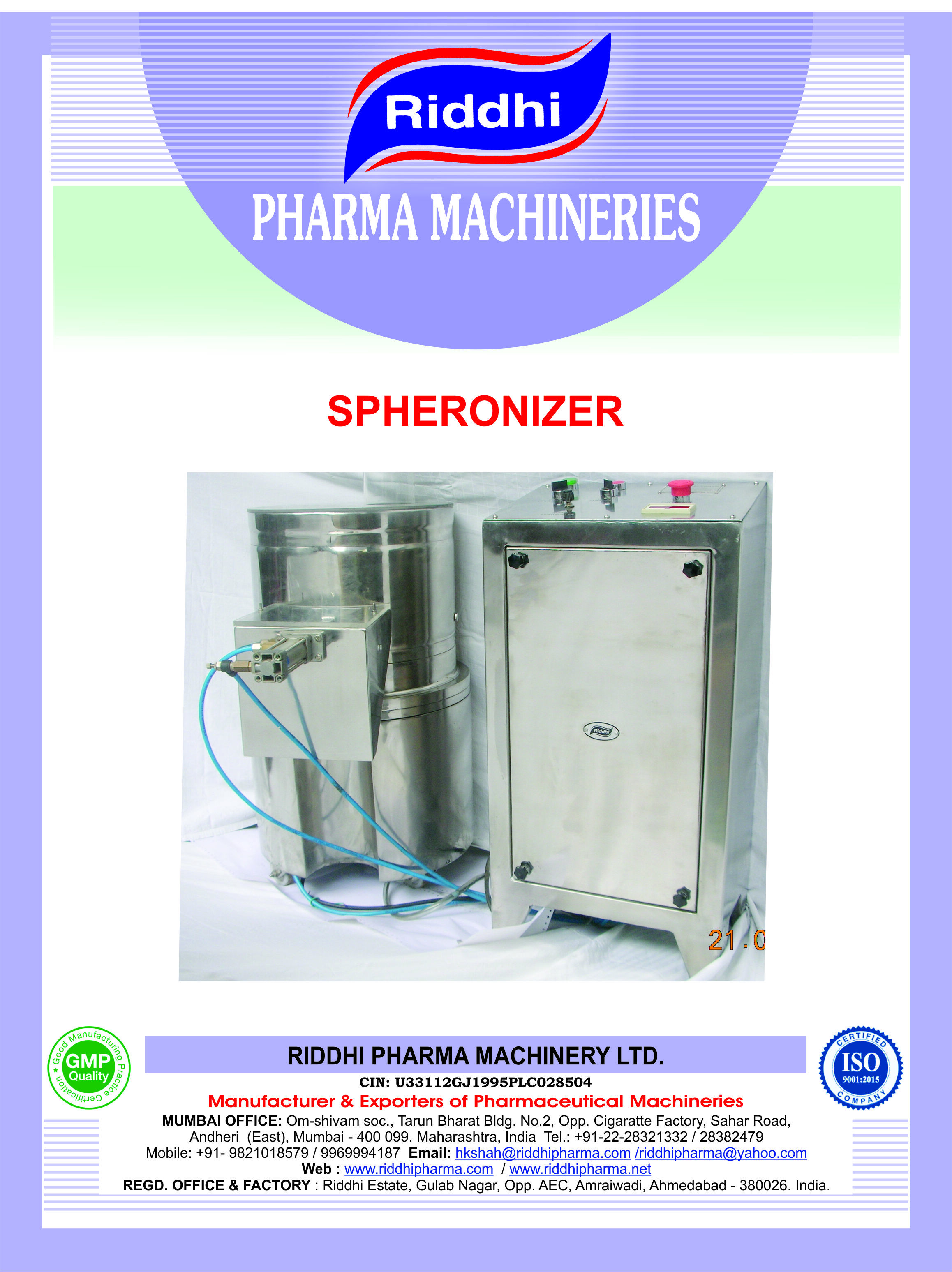

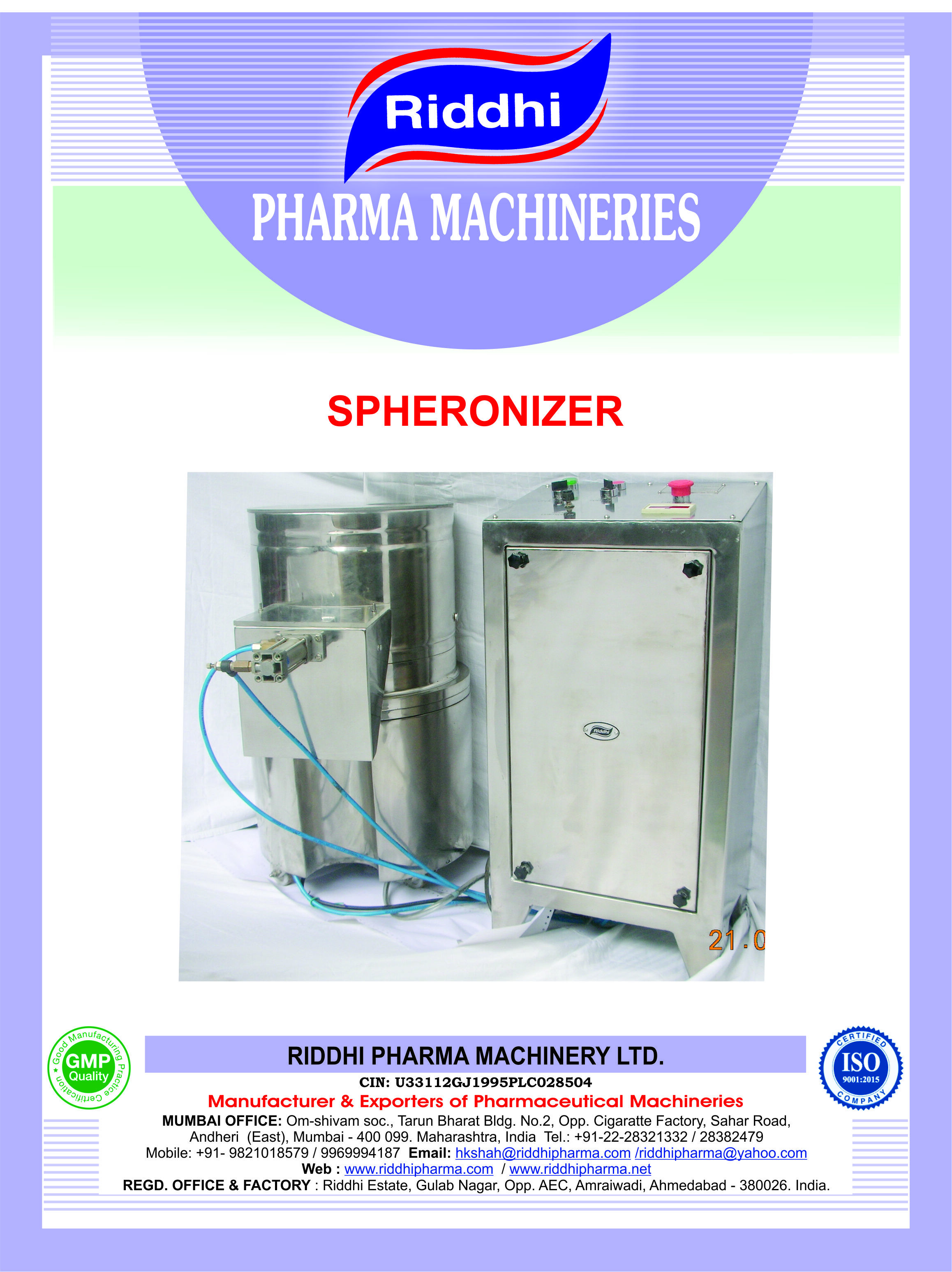

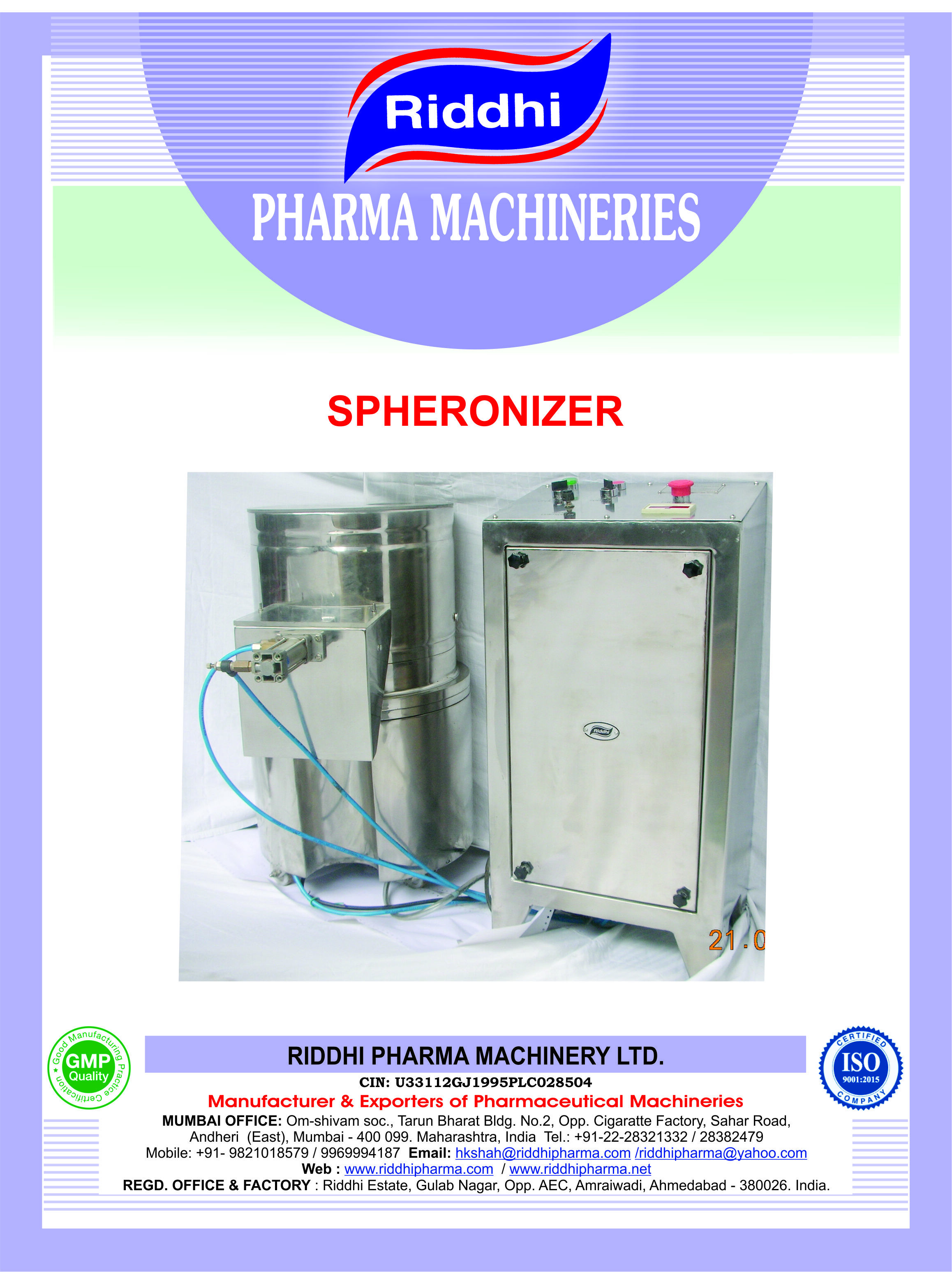

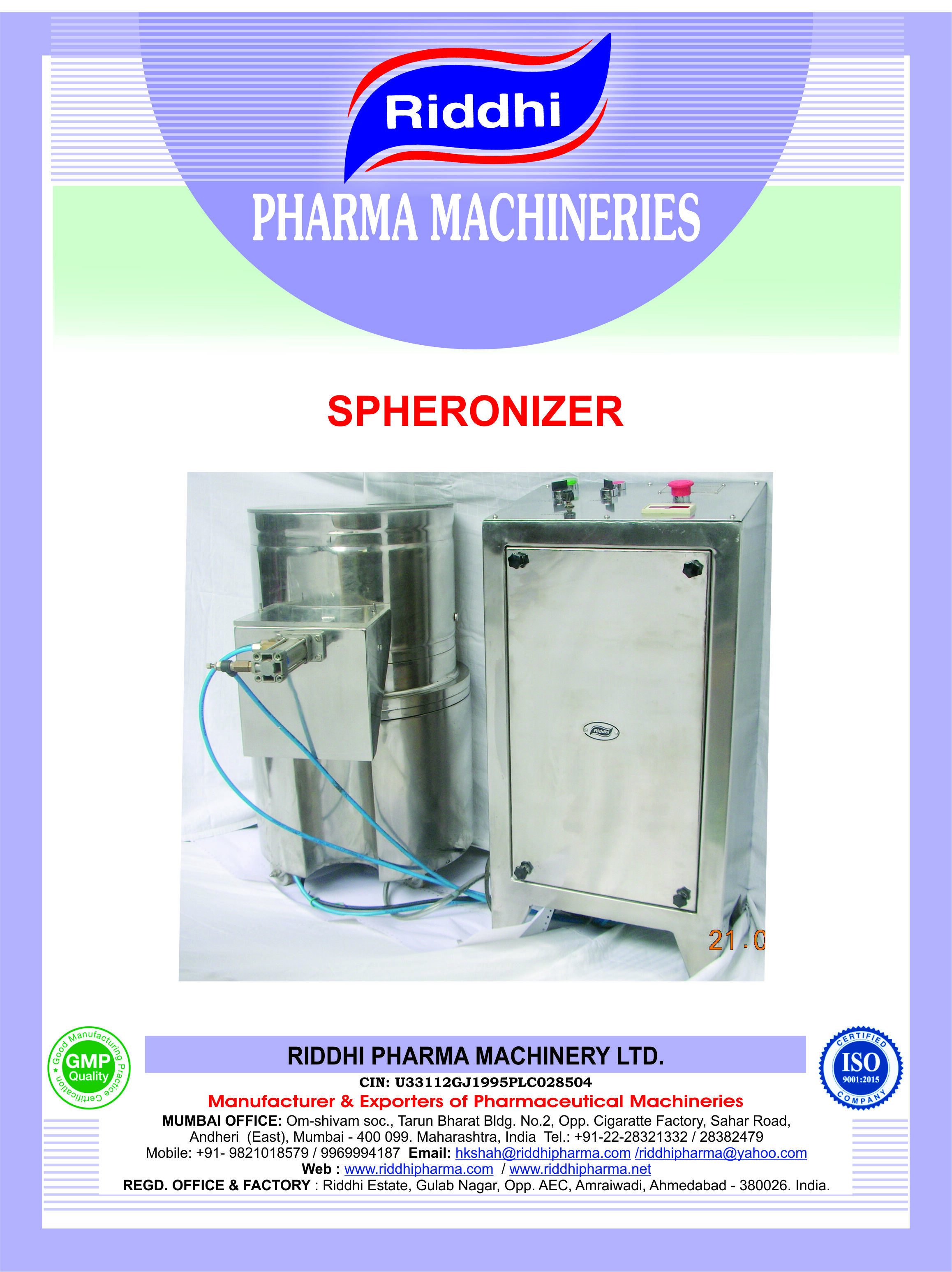

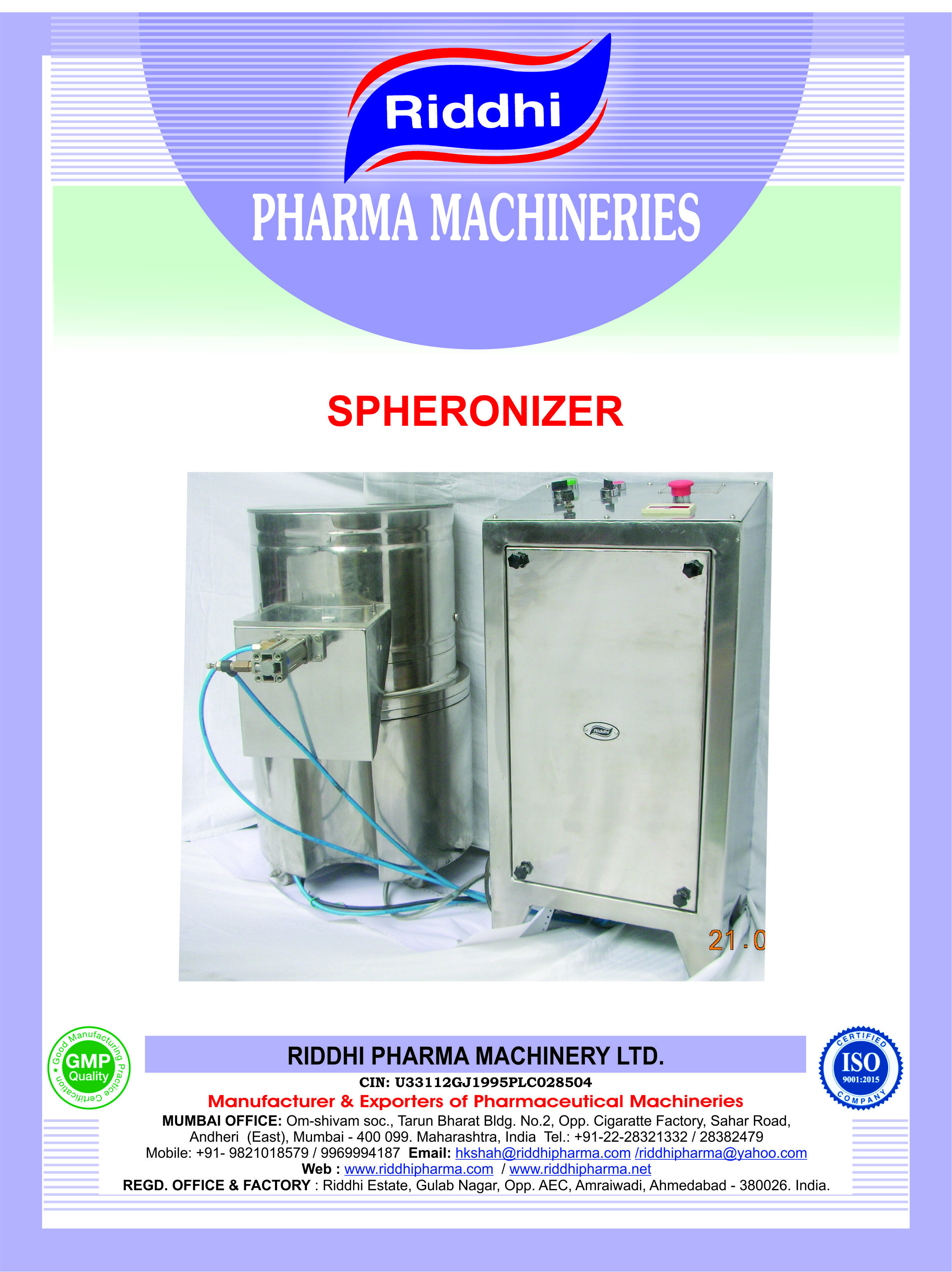

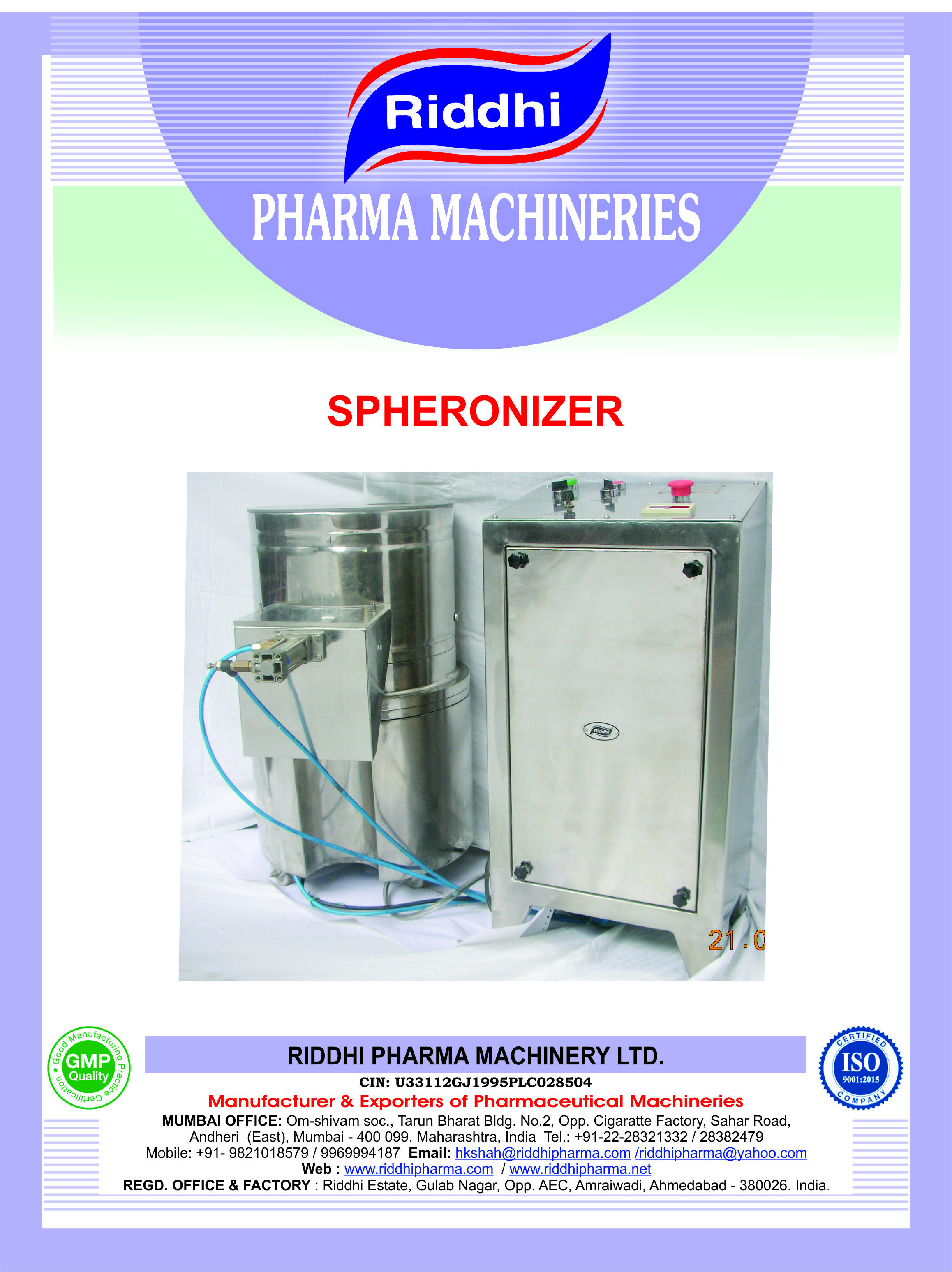

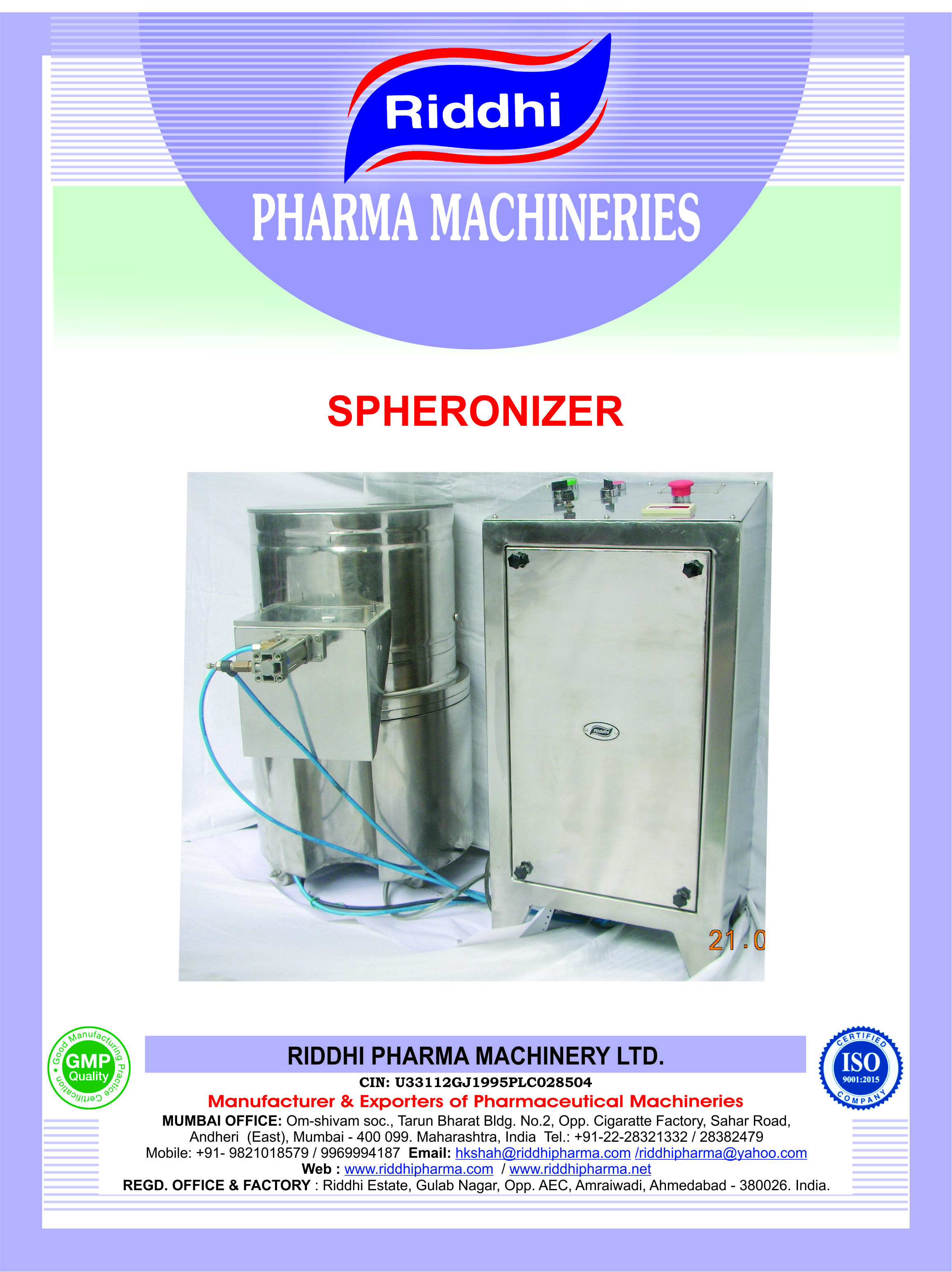

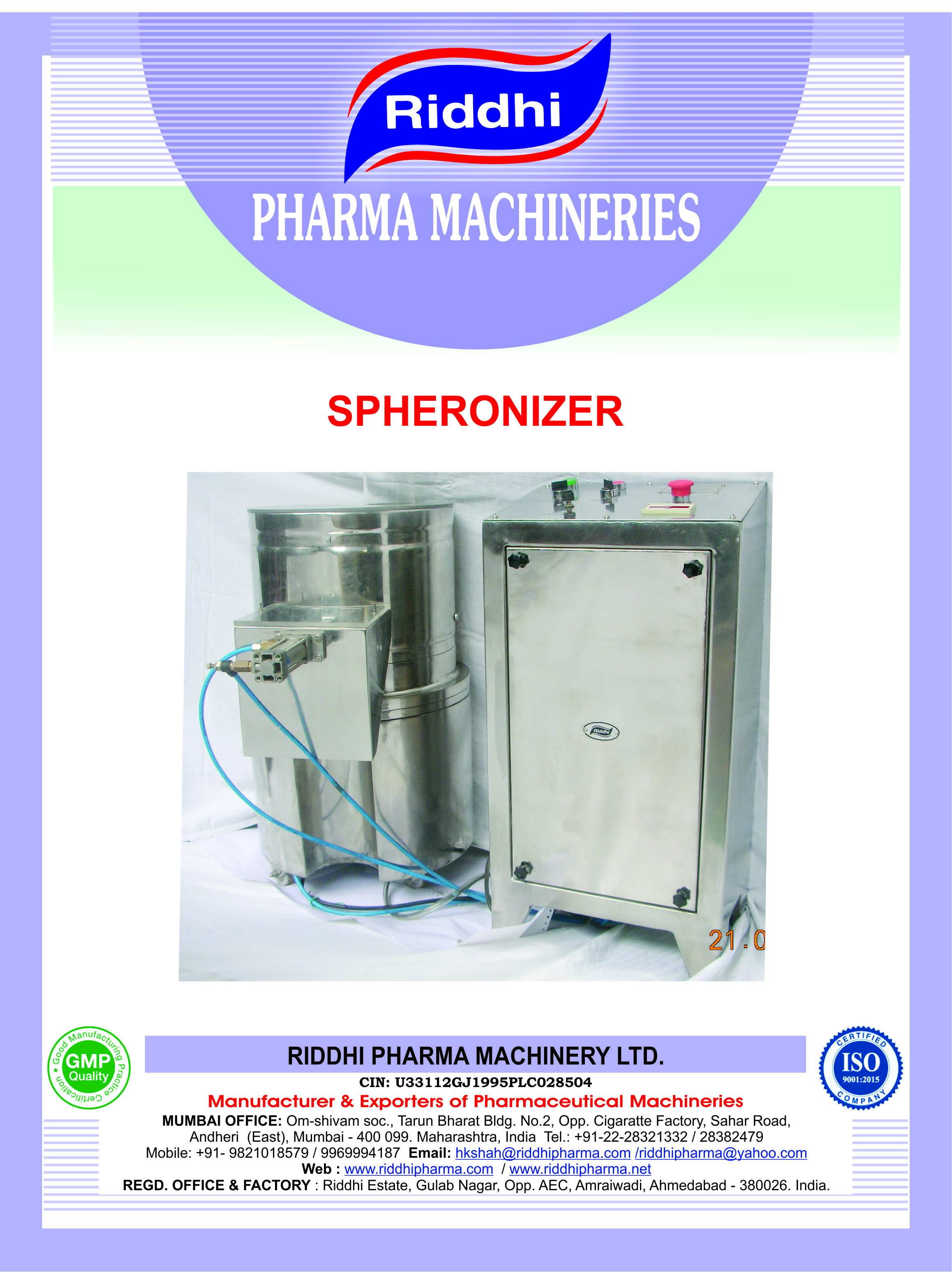

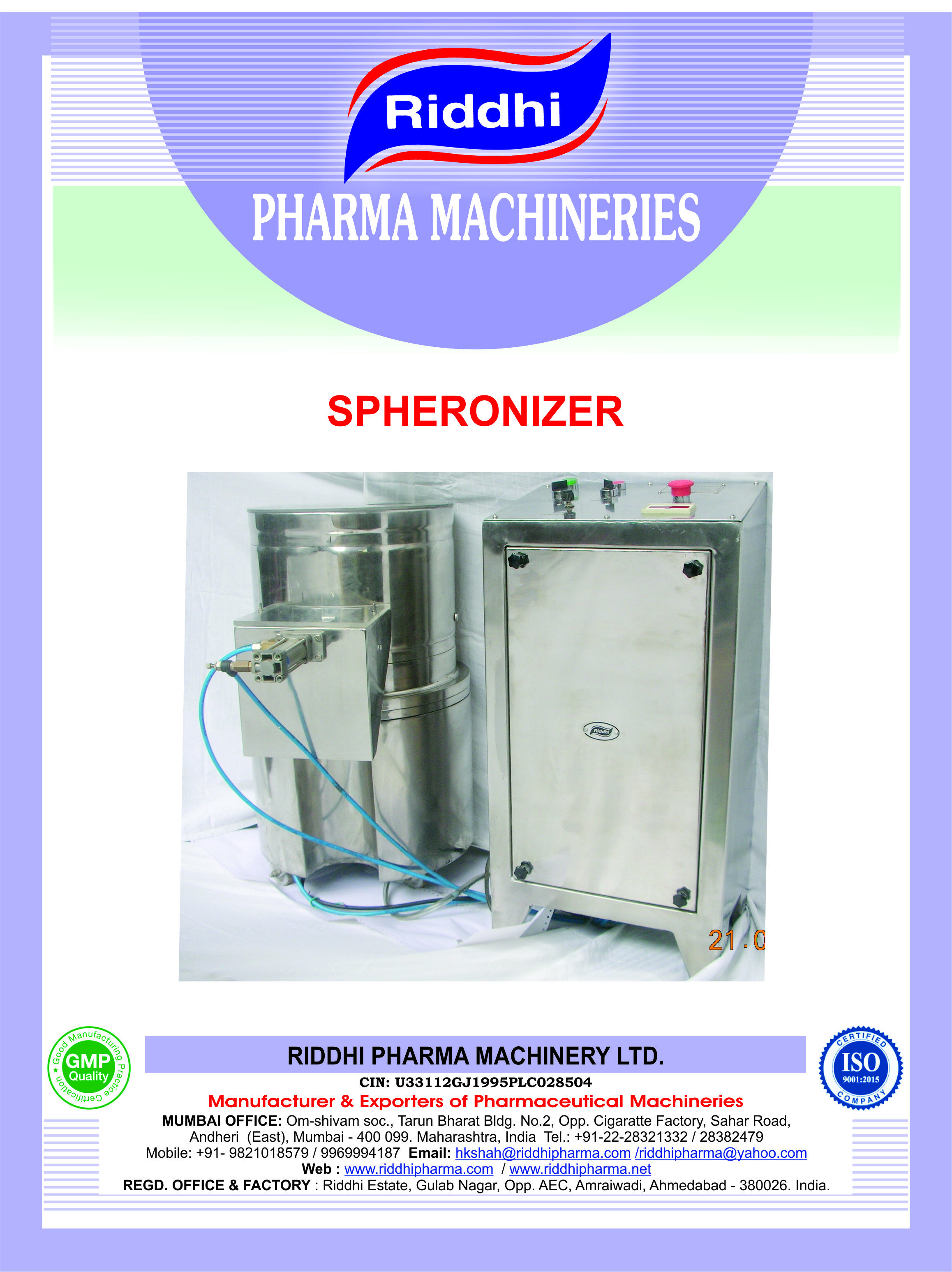

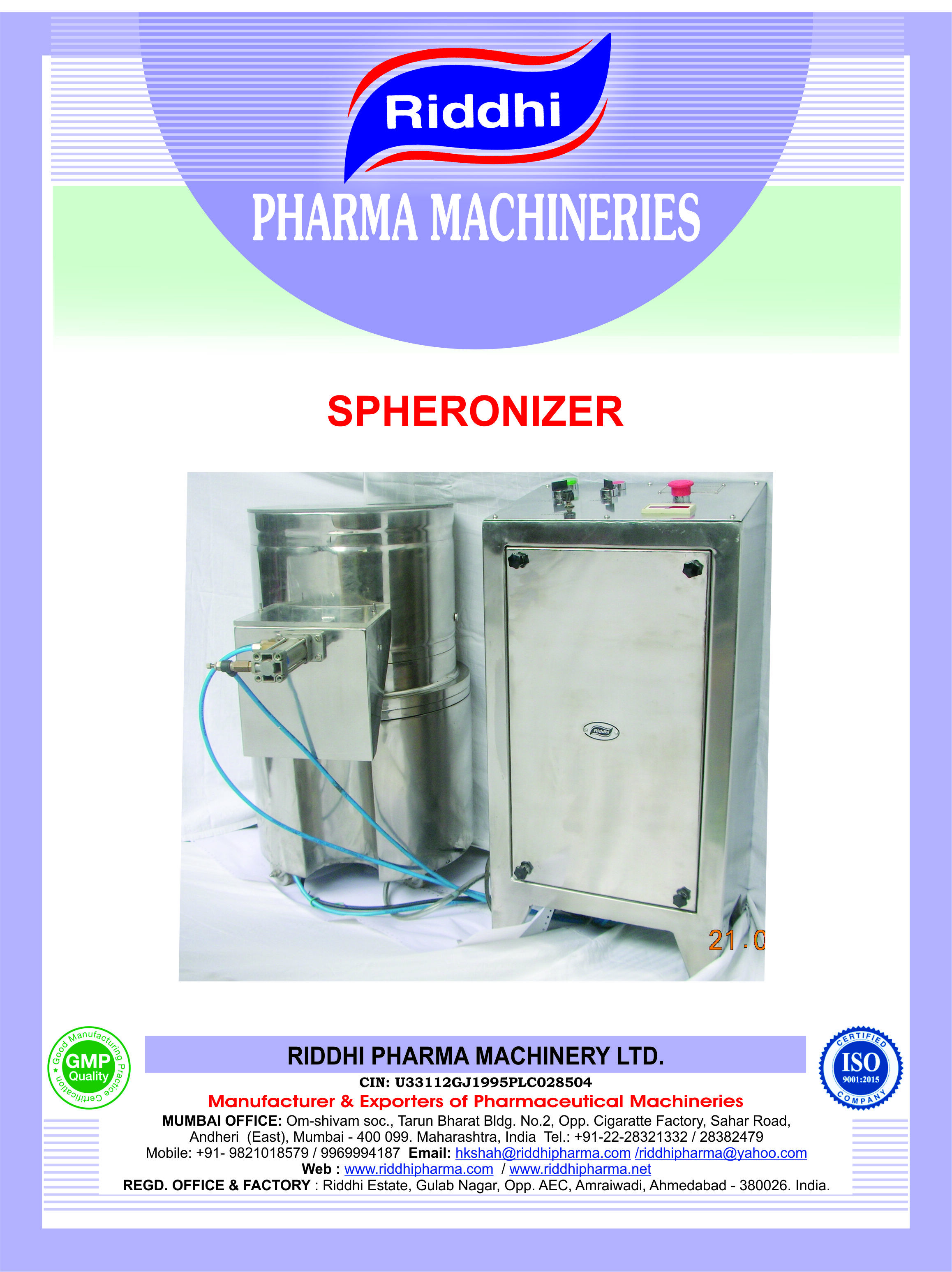

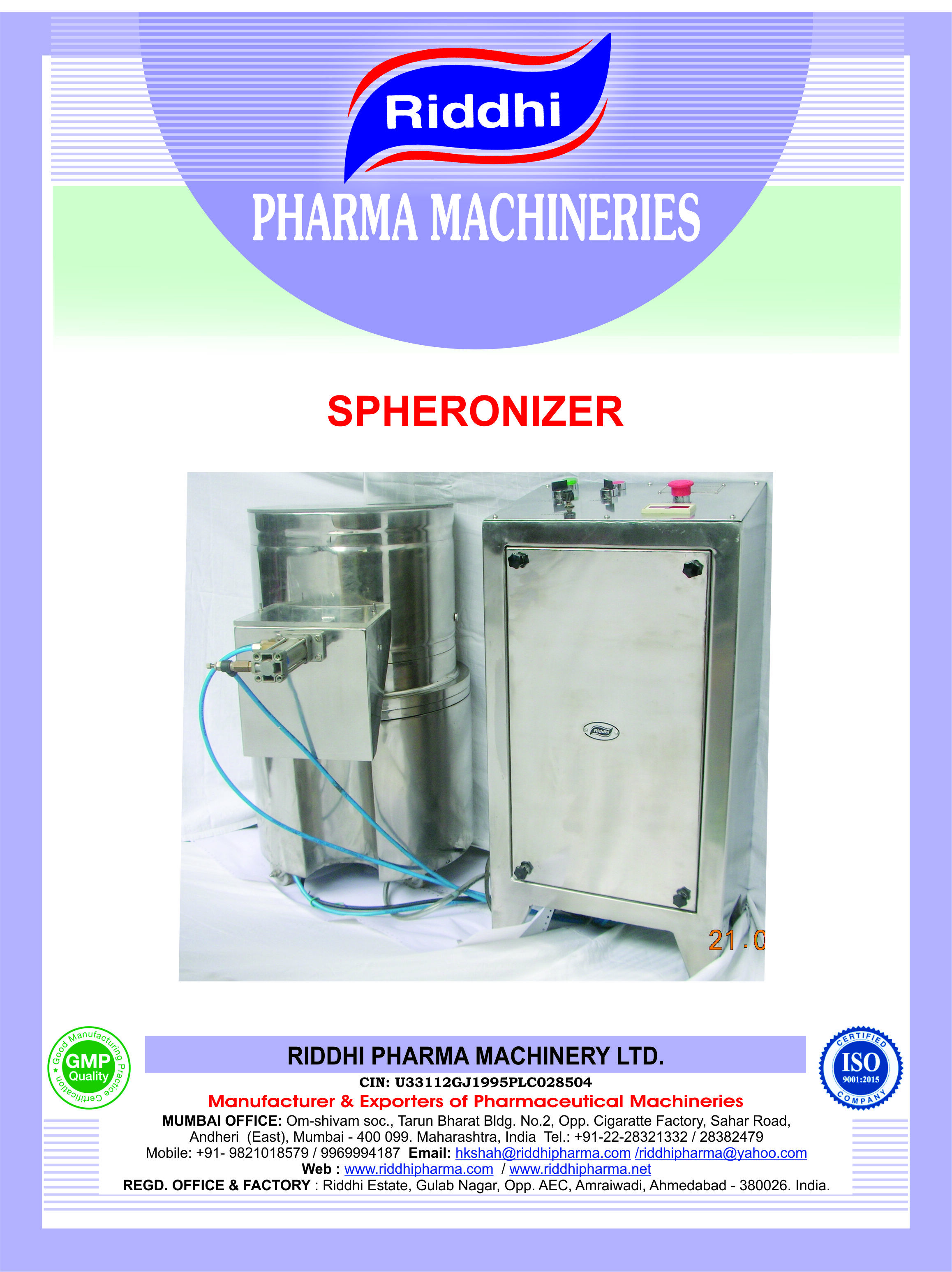

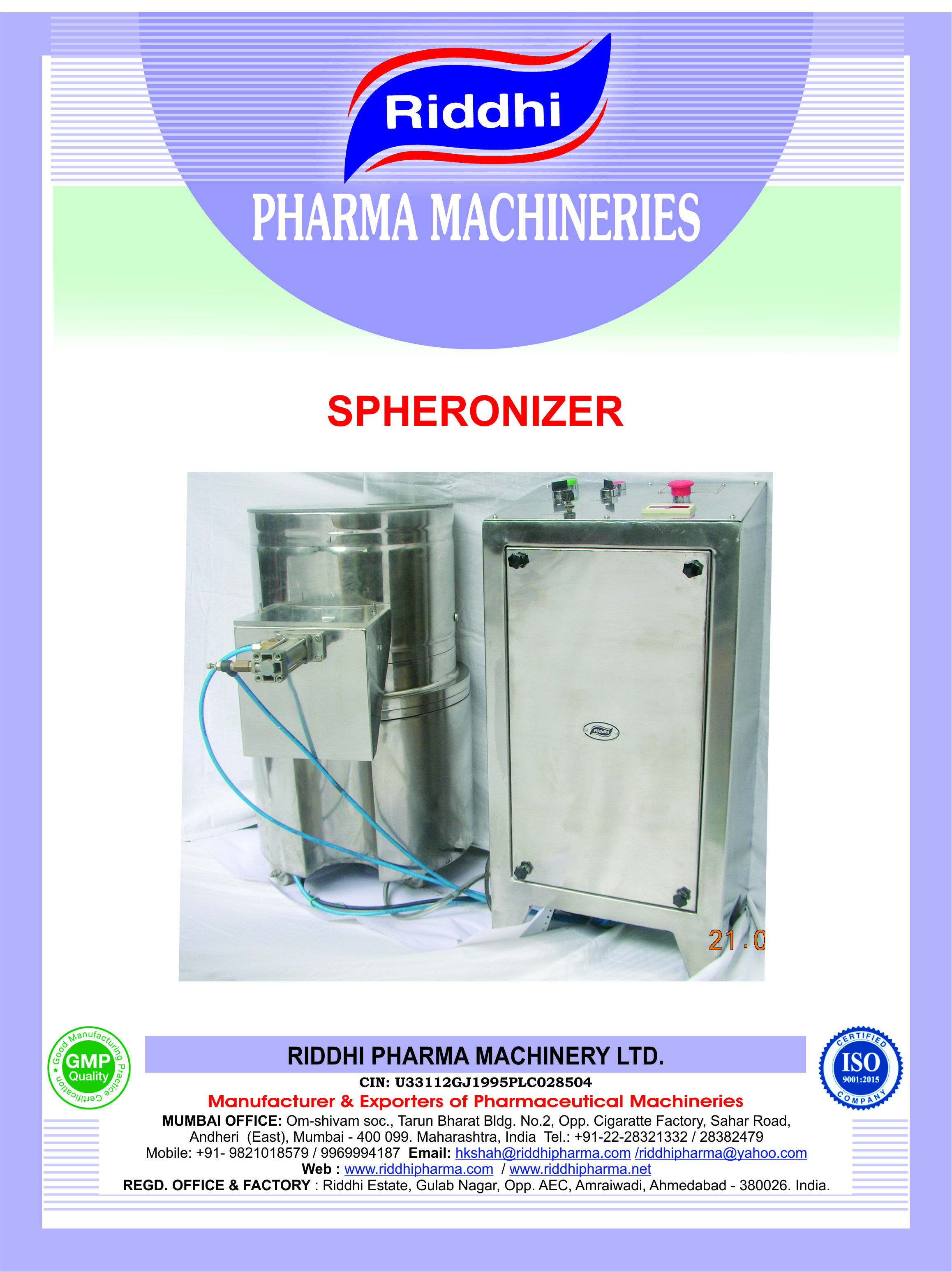

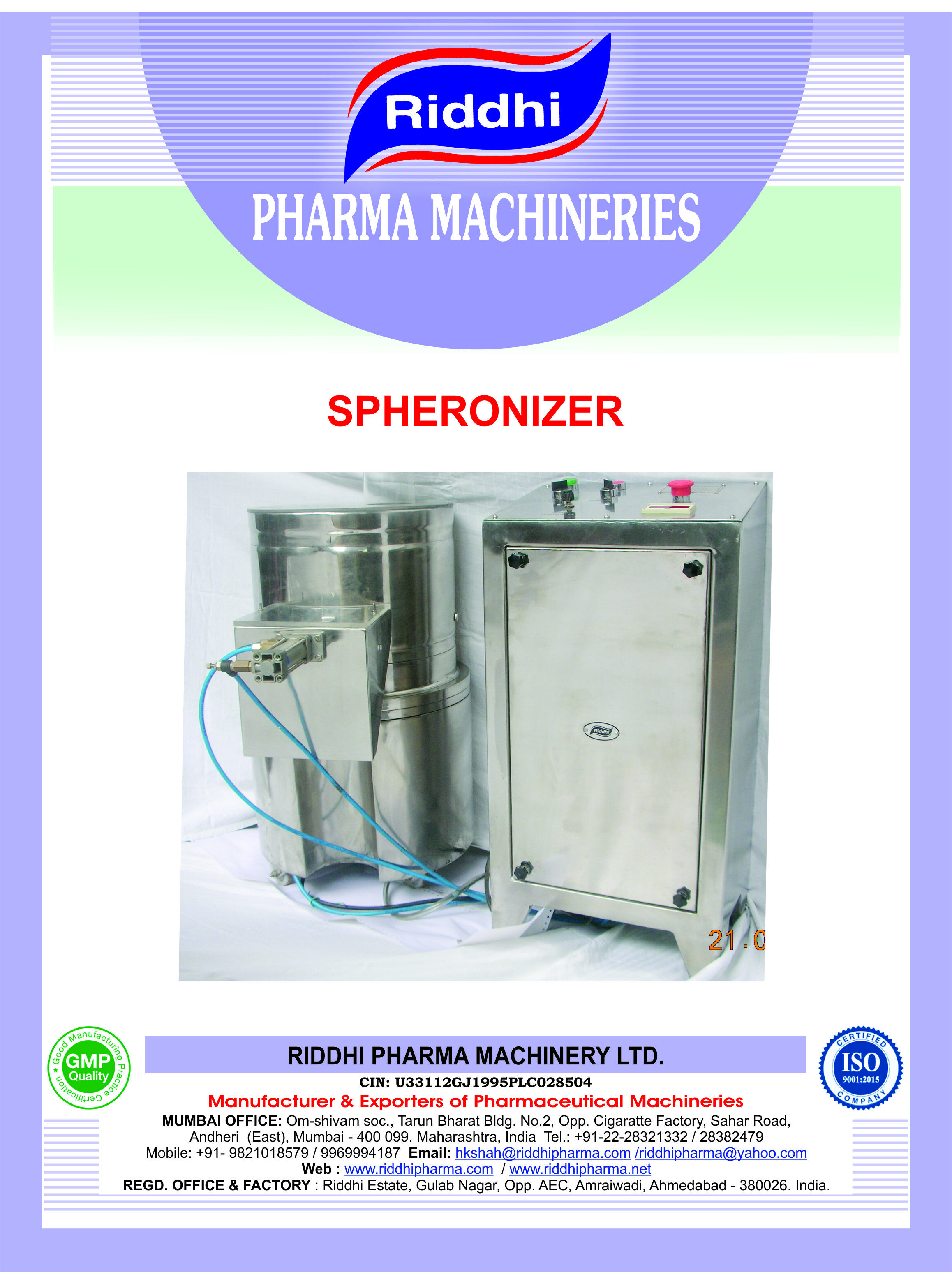

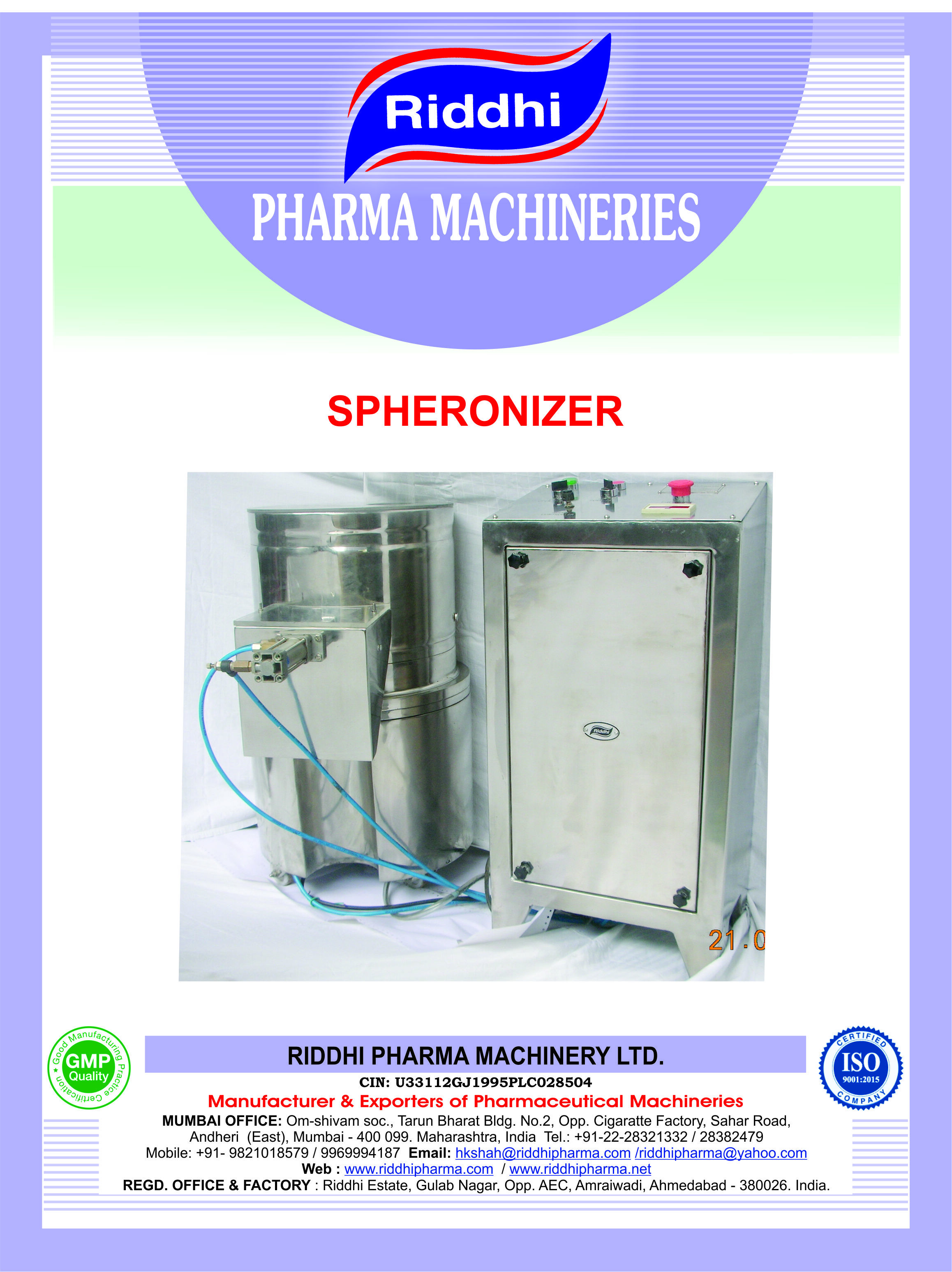

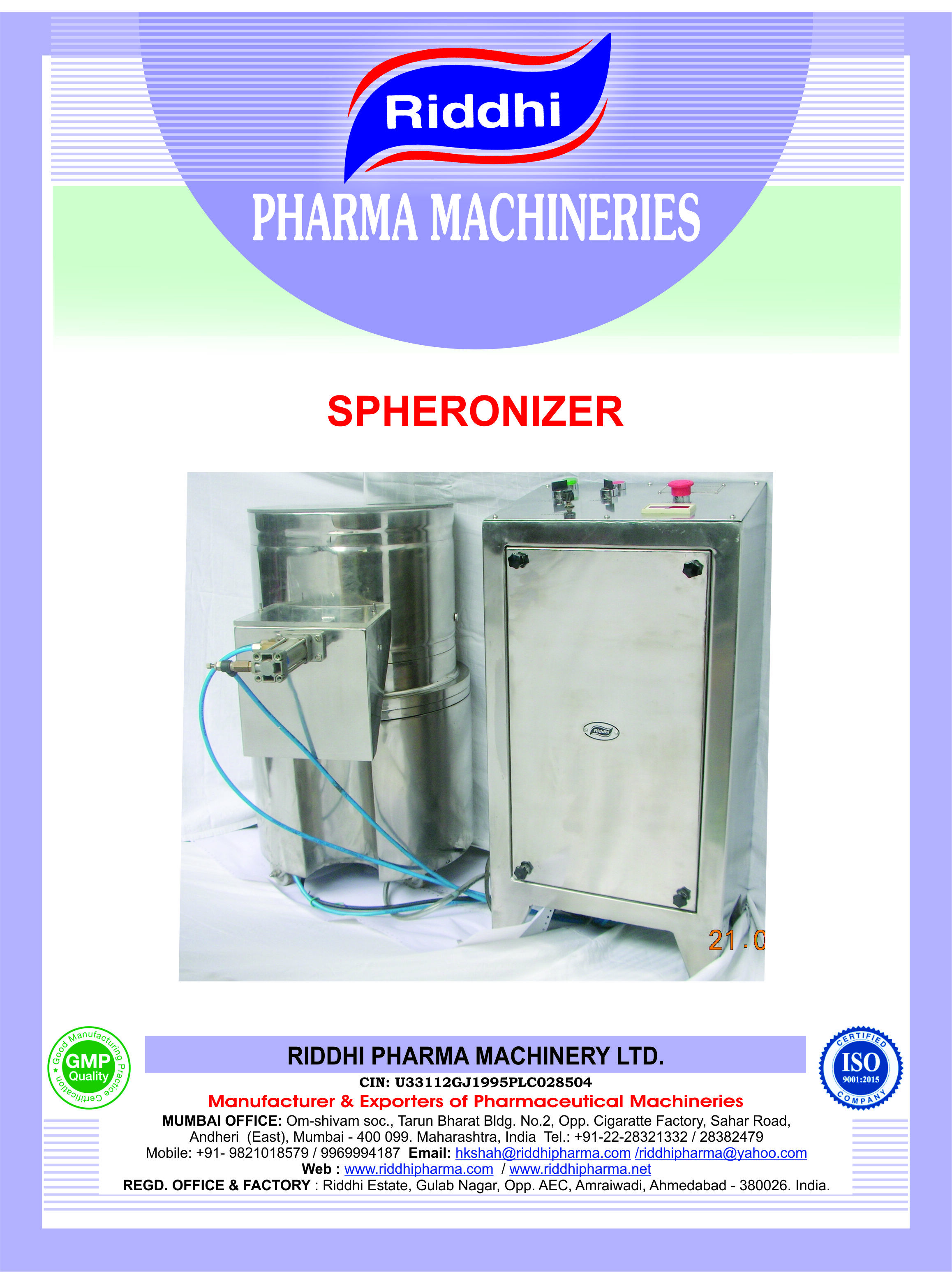

Pellet Making Machine (Spheriodiser)

Product Details:

- Type Other

- Material stainless steel

- Capacity lab model to production model Kg/hr

- Computerized Yes

- Control Mode Automatic

- Voltage 440 volts Milliampere (mA)

- Power 3 phase Milliampere (mA)

- Click to View more

Pellet Making Machine (Spheriodiser) Price And Quantity

- 550000 INR/Unit

- 3 Unit

Pellet Making Machine (Spheriodiser) Product Specifications

- Yes

- 225 Kilograms (kg)

- one year warranty

- Automatic

- 101.6 x 101.6 x 127 Millimeter (mm)

- Other

- lab model to production model Kg/hr

- 3 phase Milliampere (mA)

- 440 volts Milliampere (mA)

- stainless steel

- stainless steel

Pellet Making Machine (Spheriodiser) Trade Information

- MUMBAI JNPT PORT

- 1 Unit Per Month

- 6-8 Week

- SEA WORTHY PACKING

- All India

Product Description

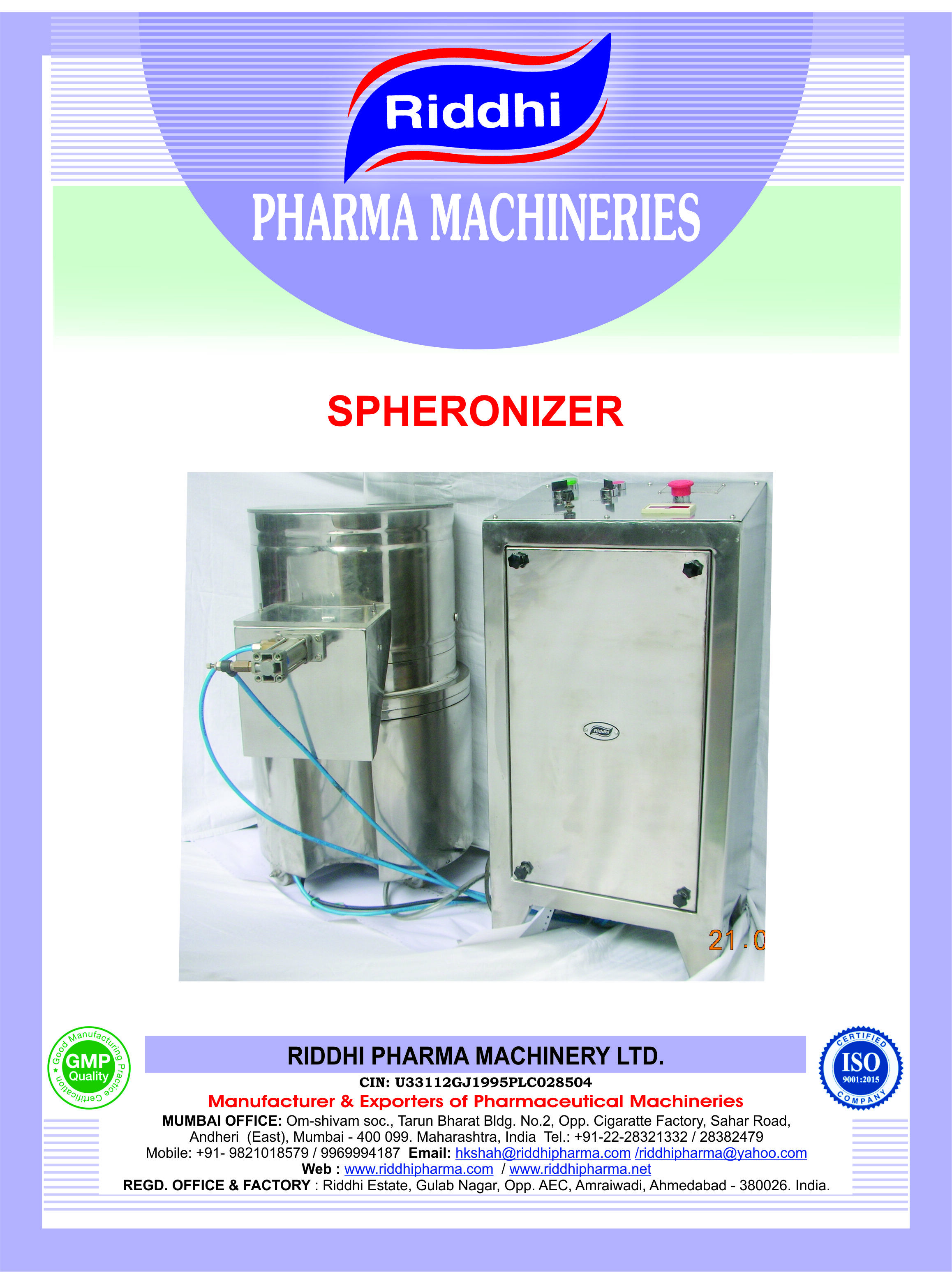

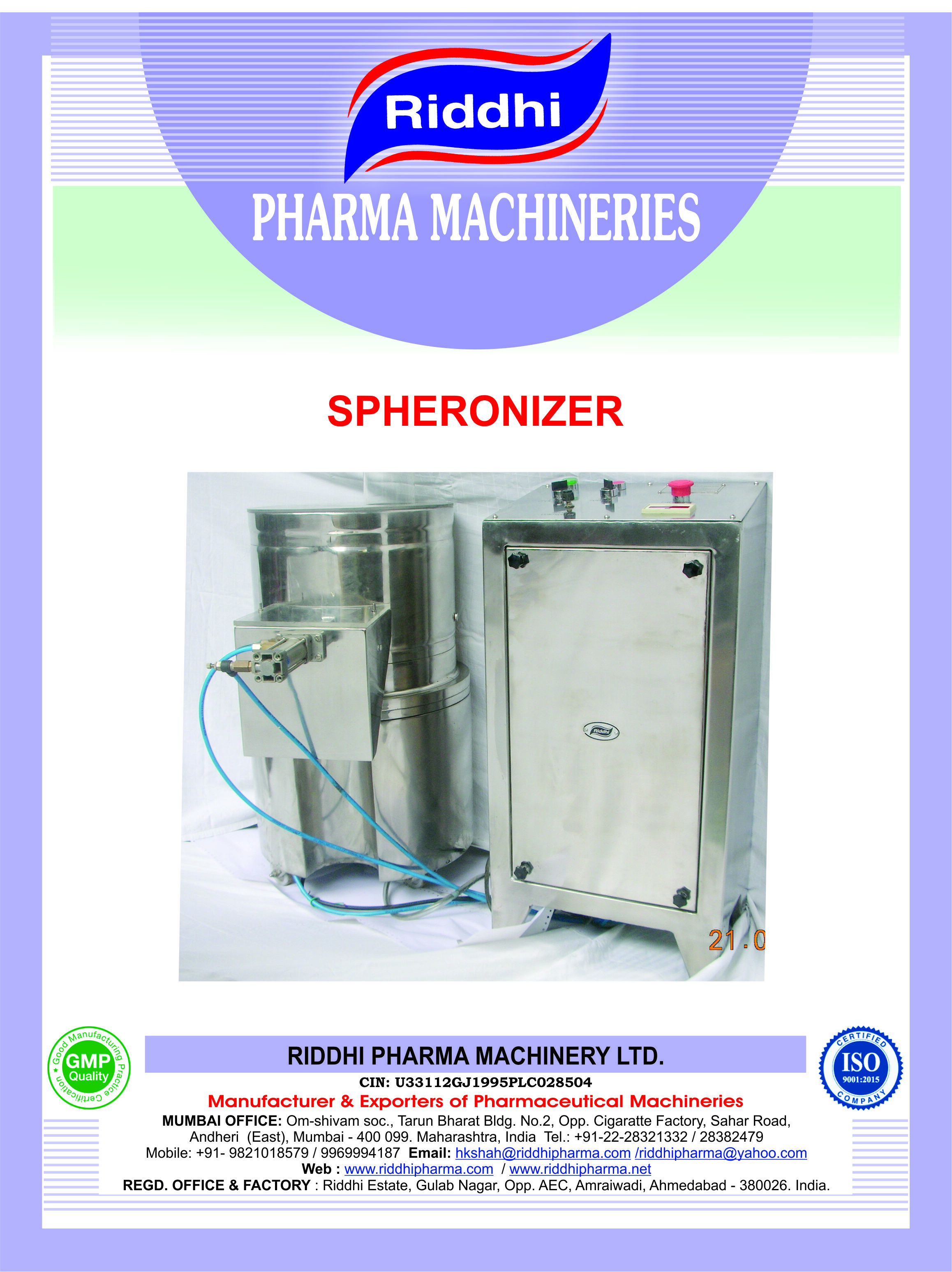

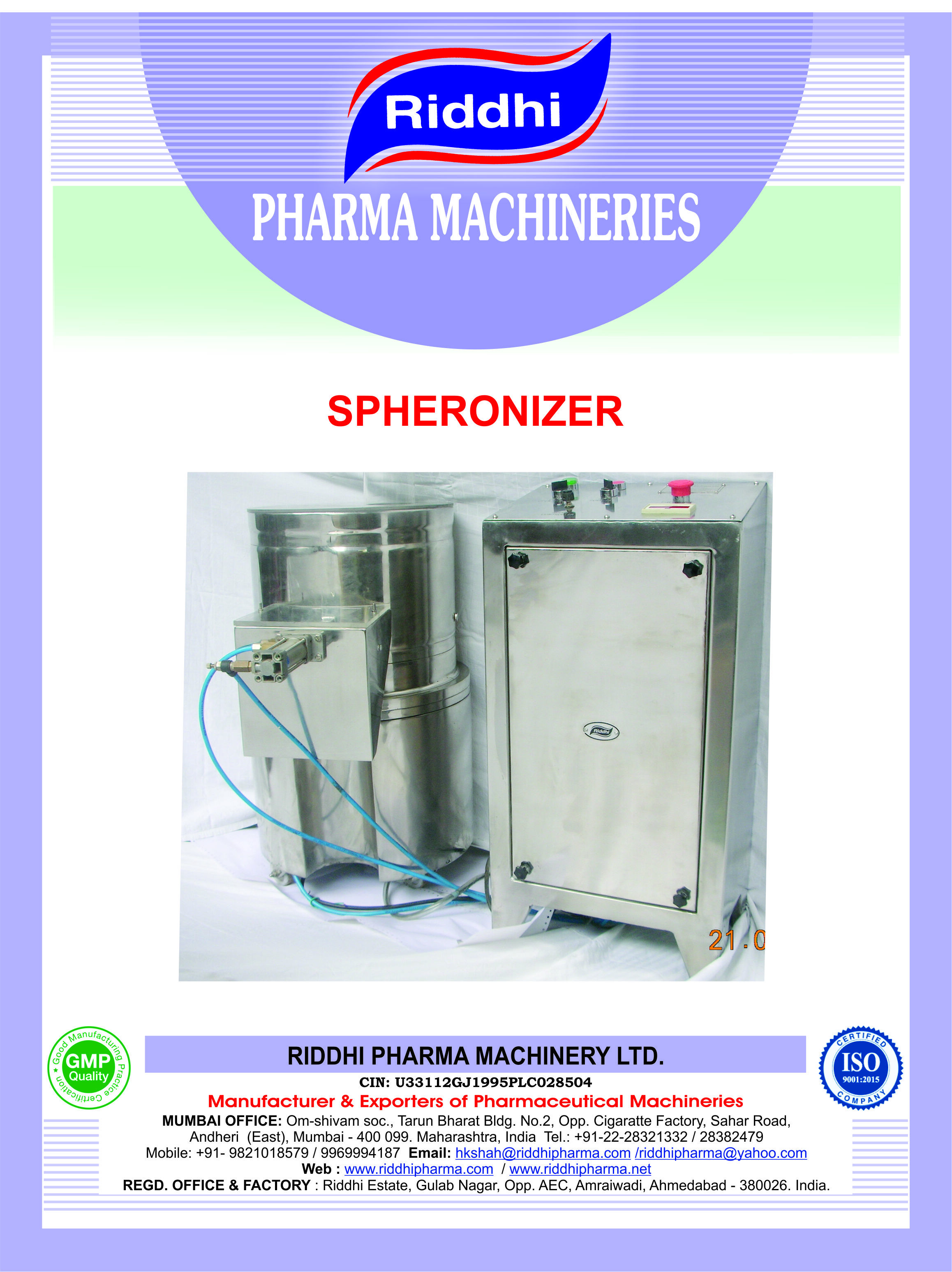

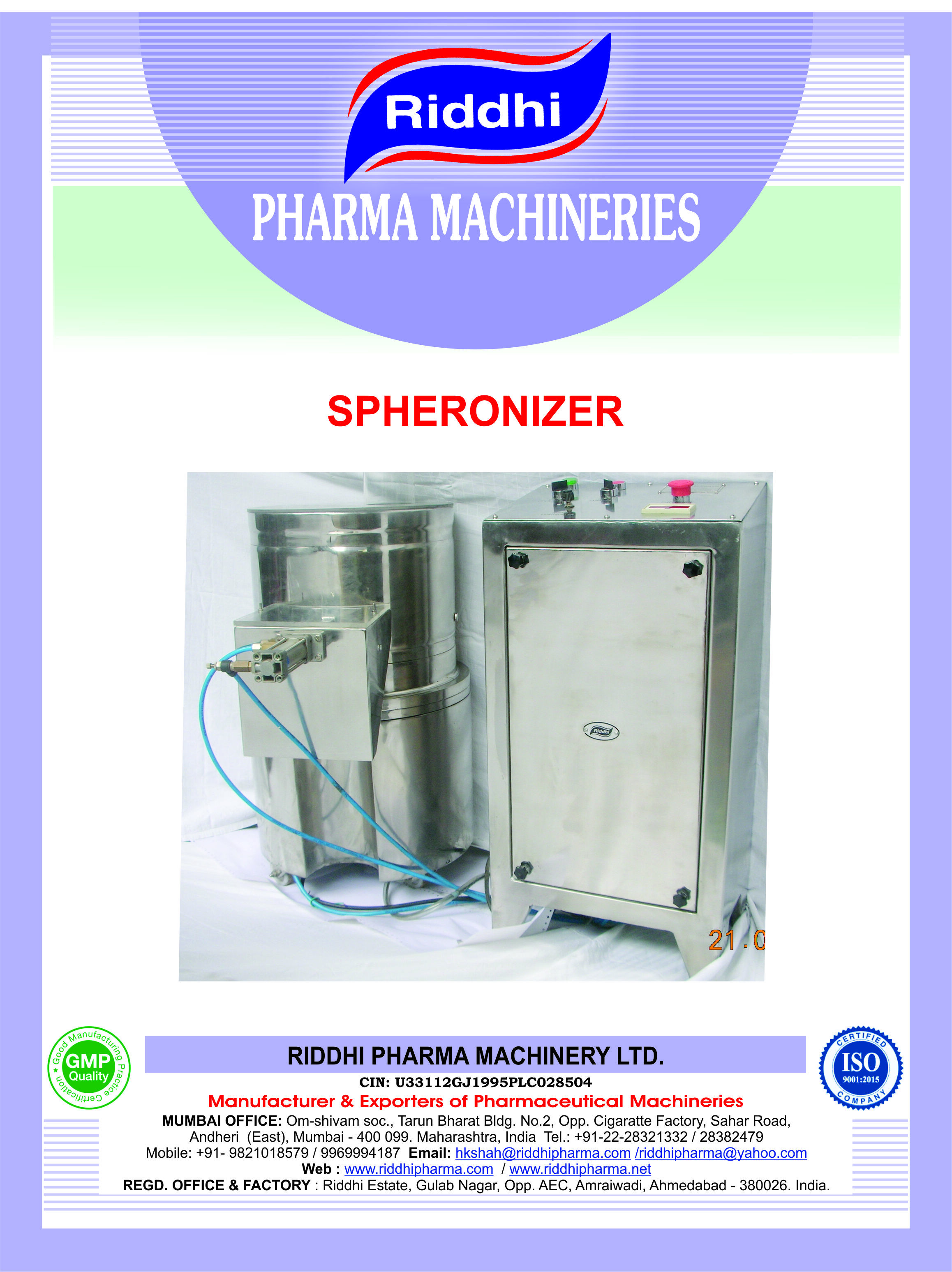

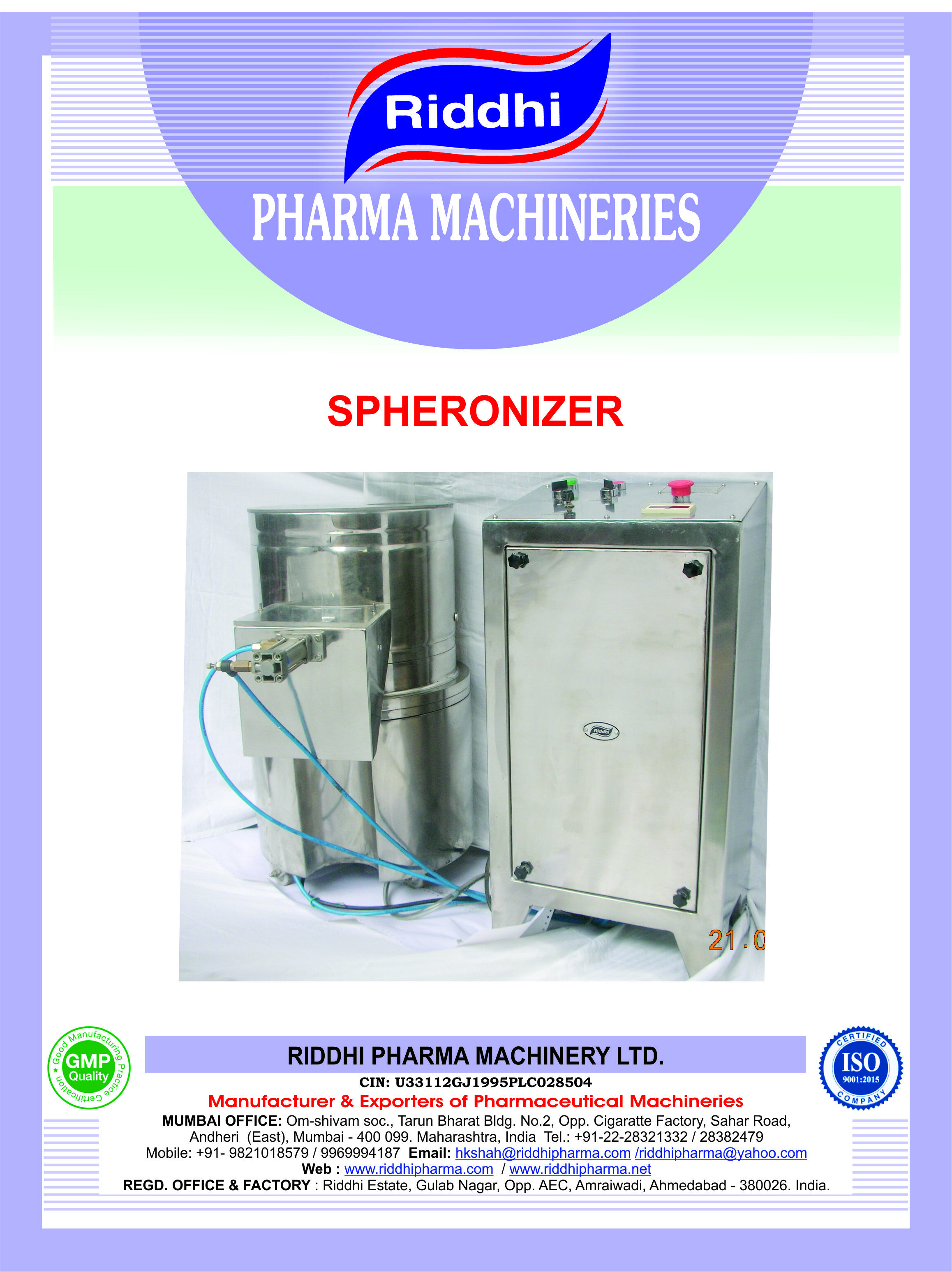

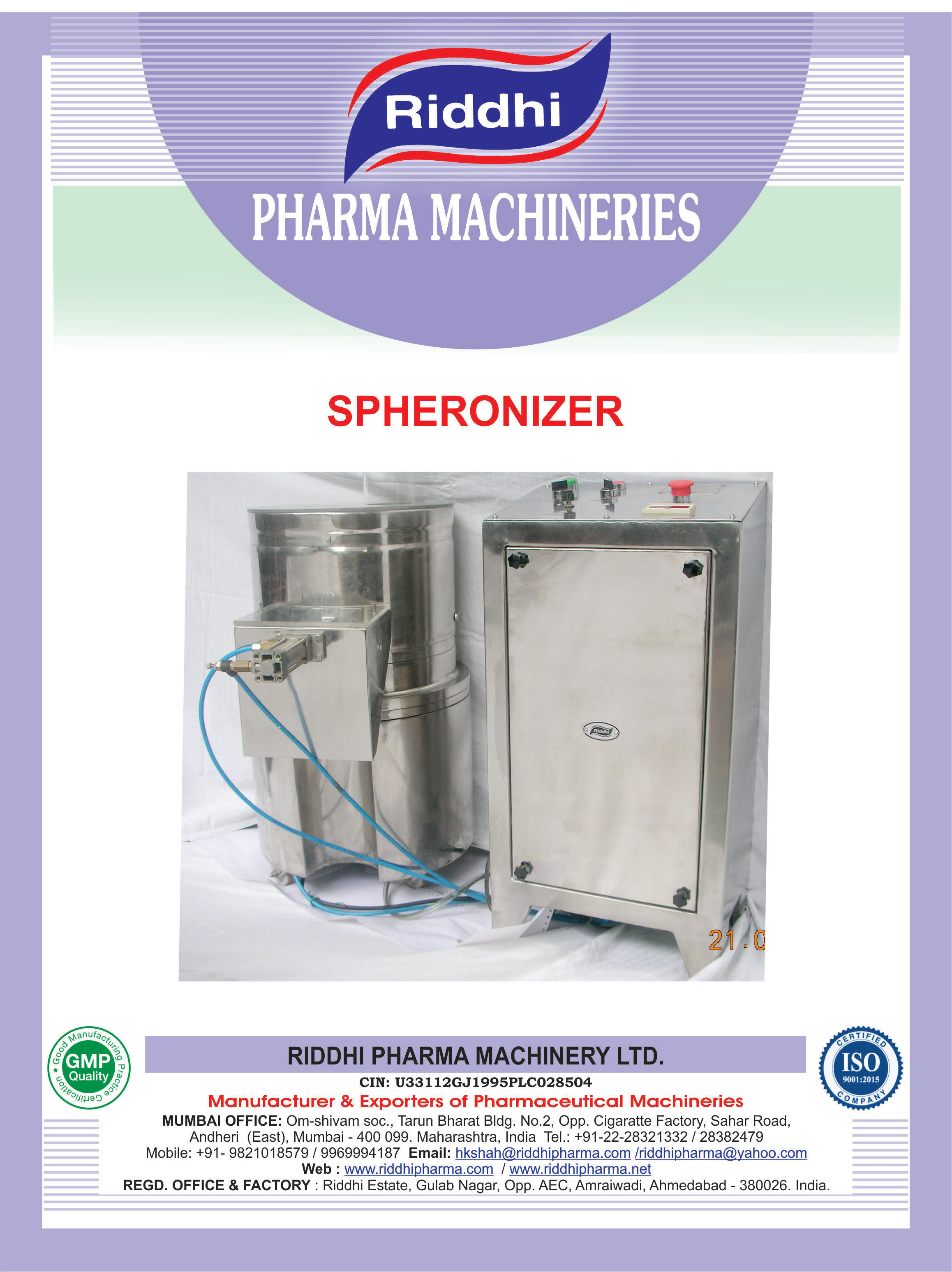

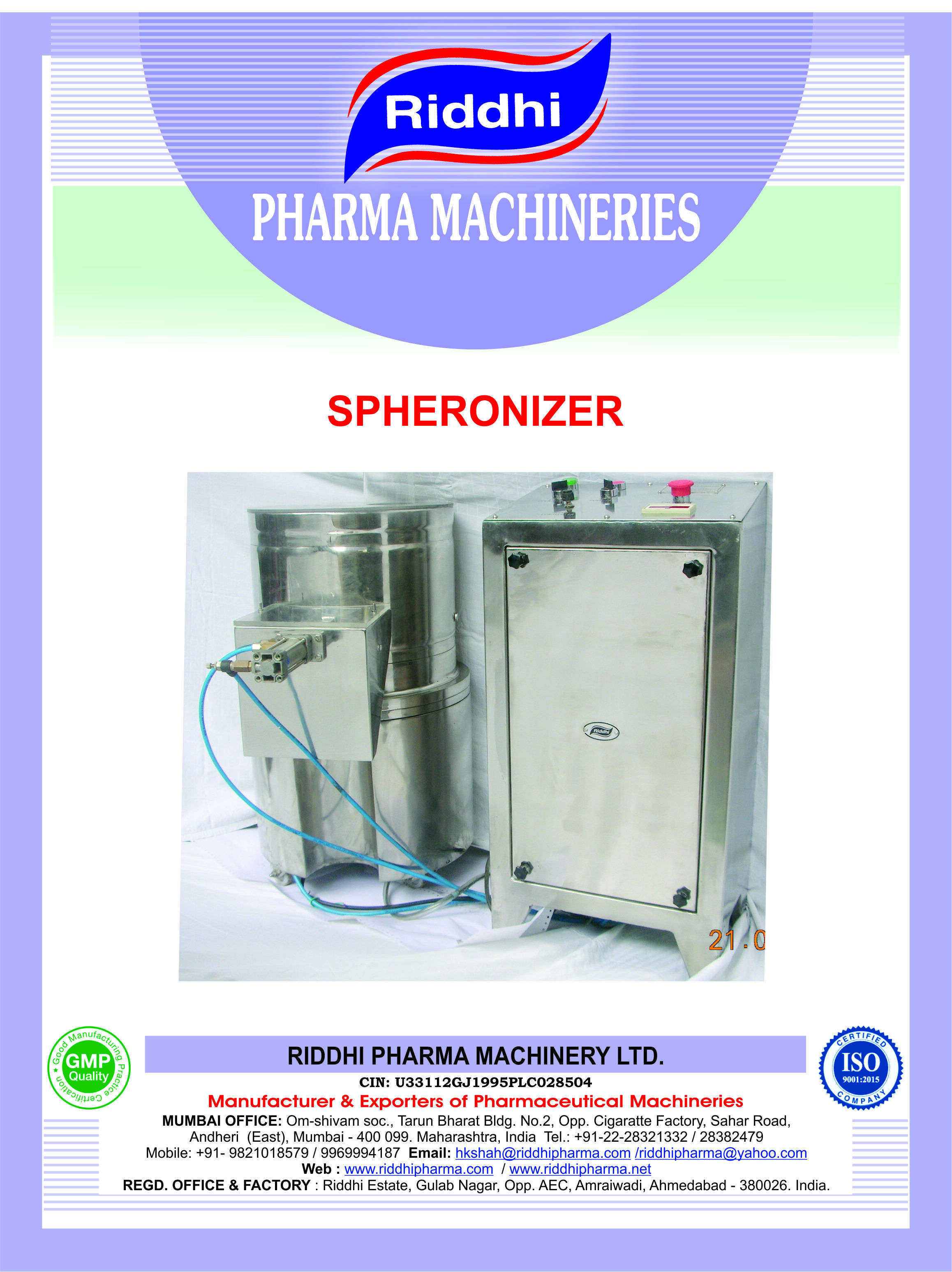

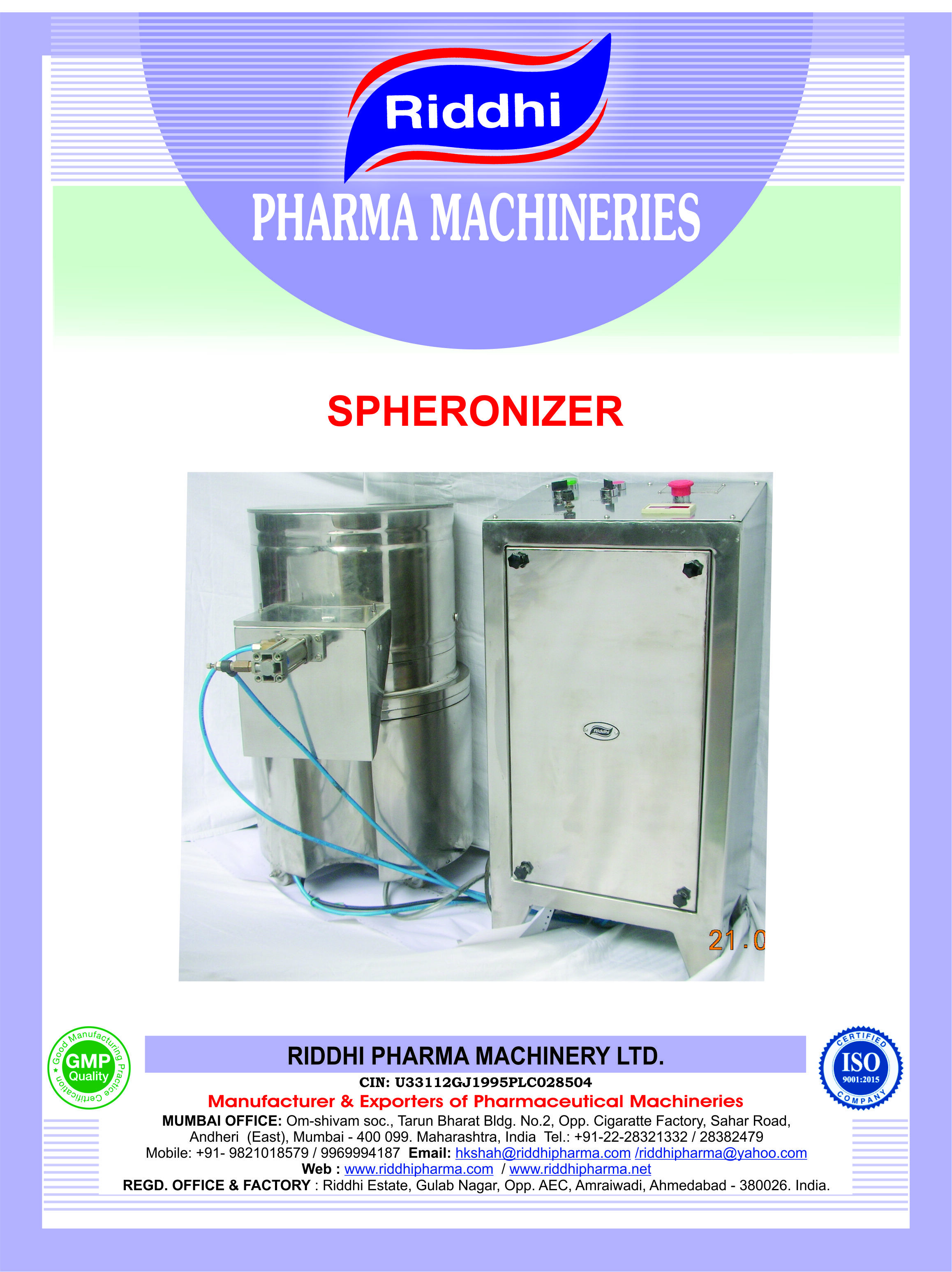

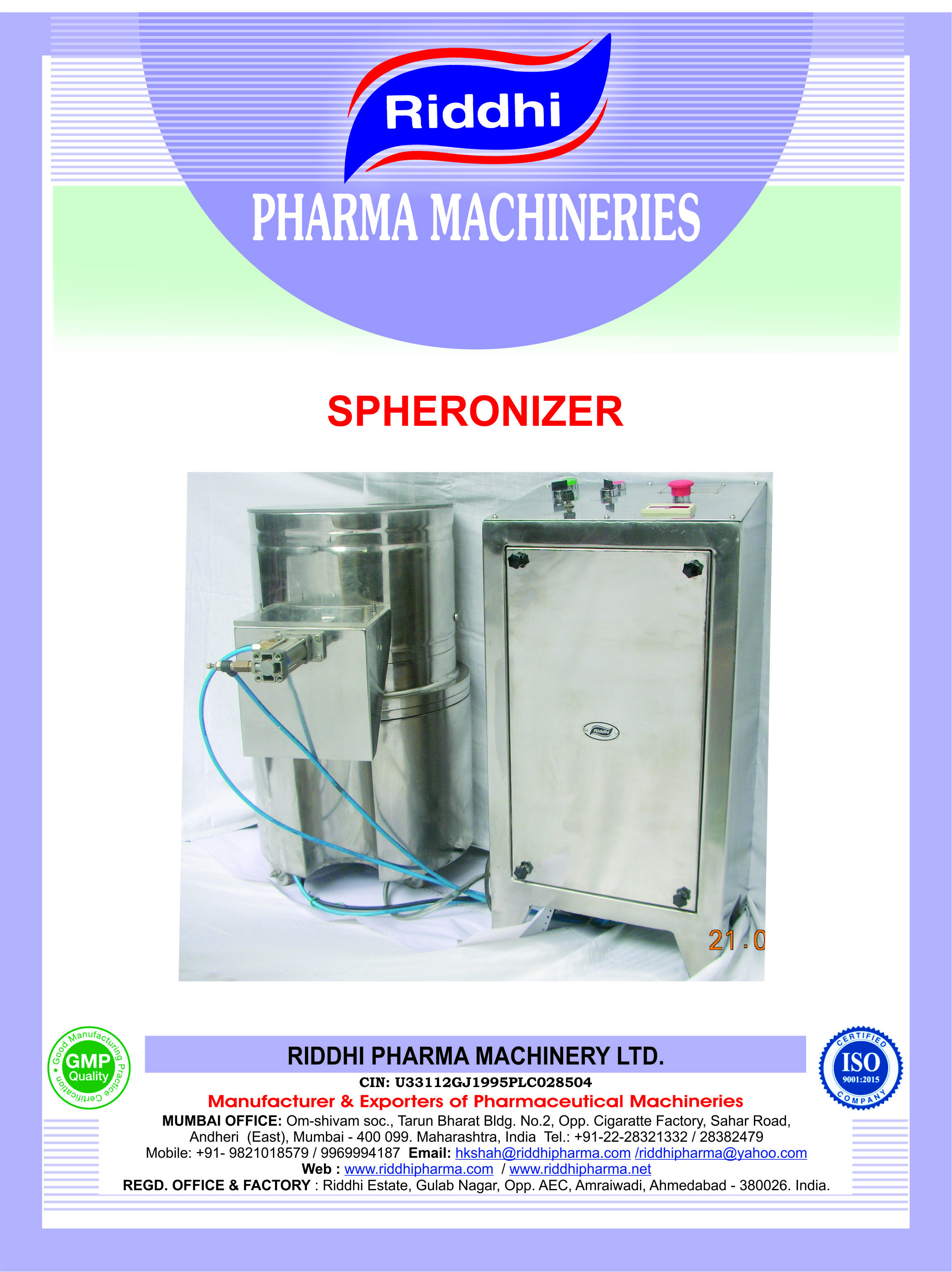

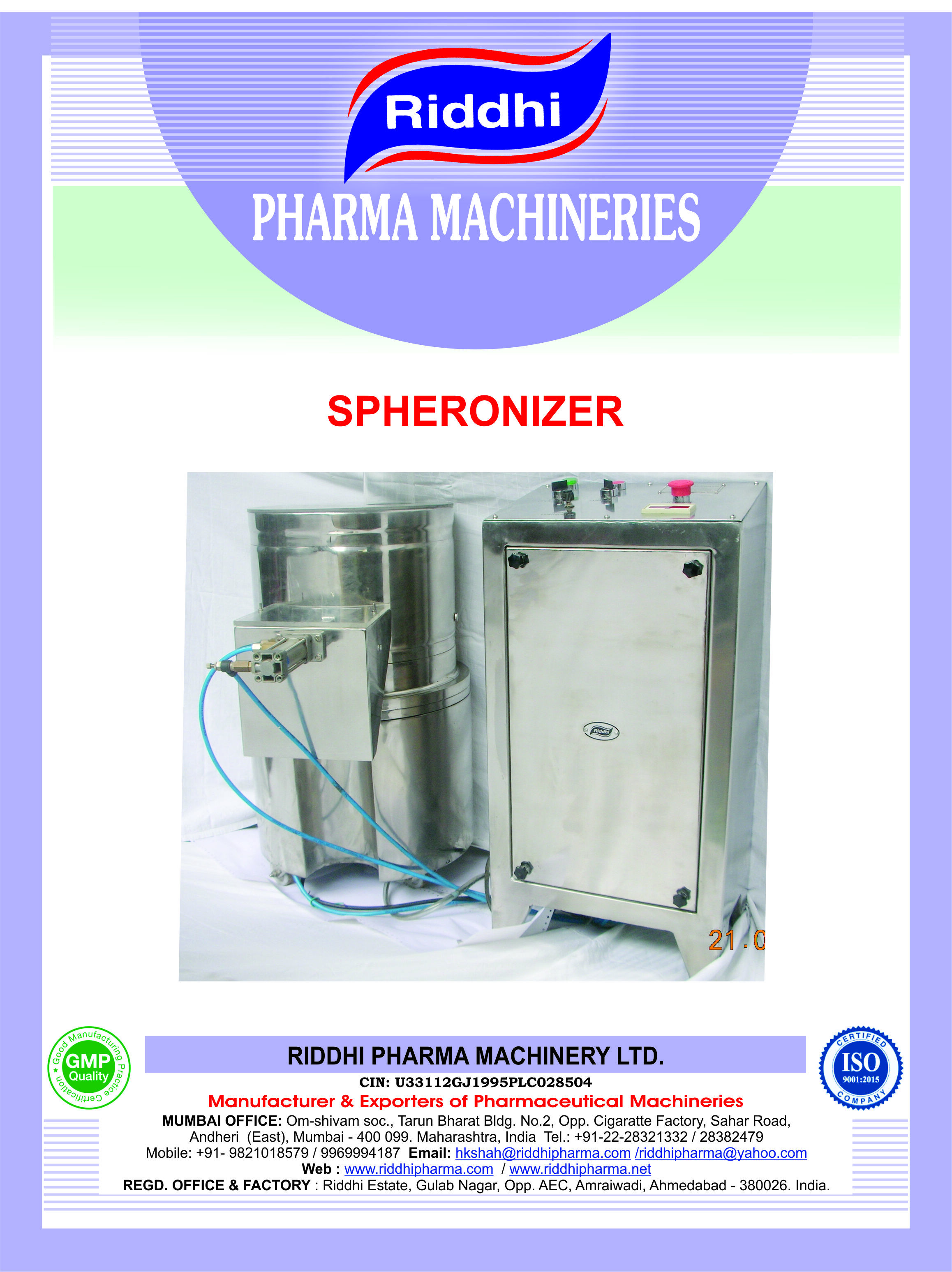

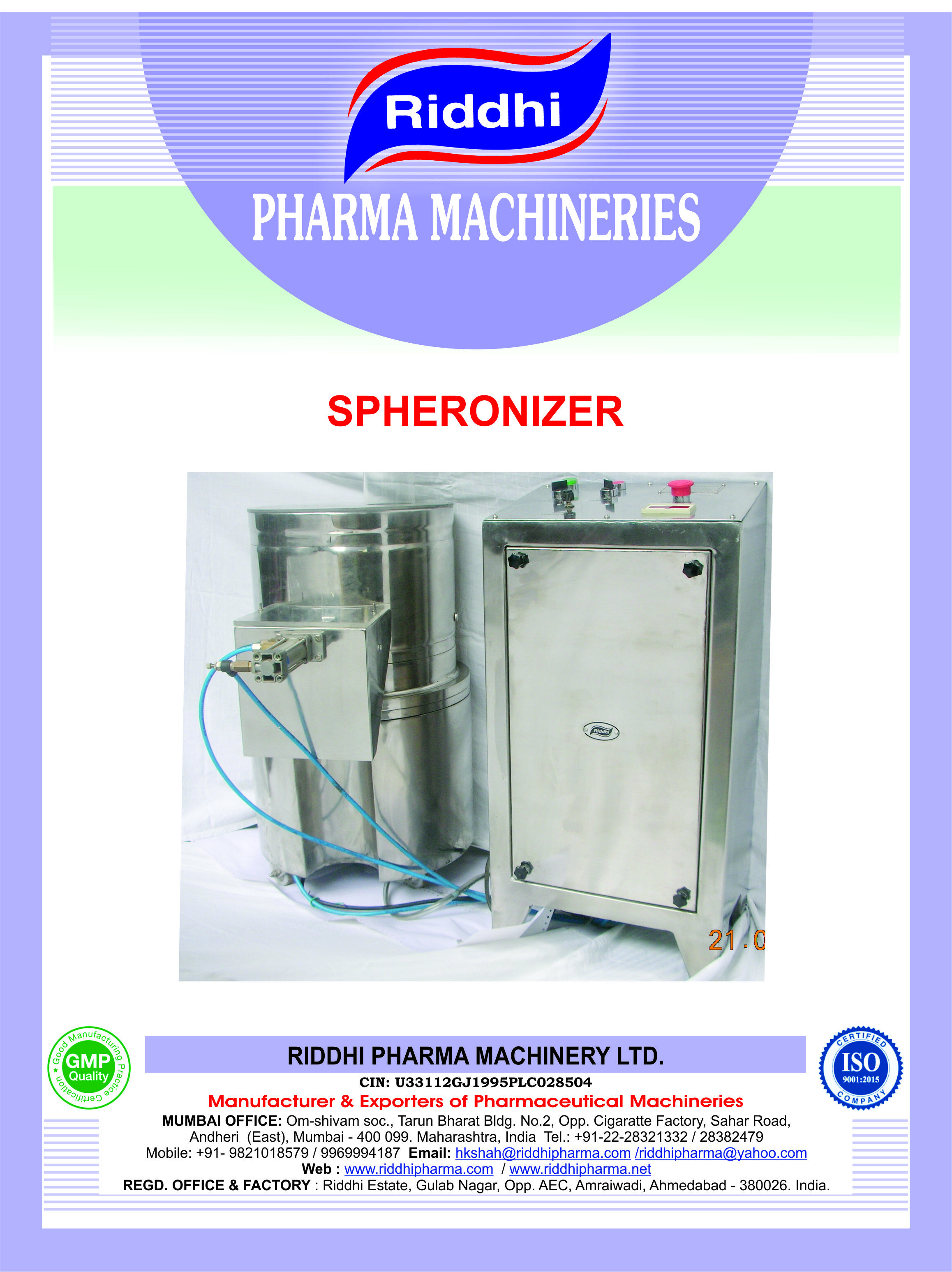

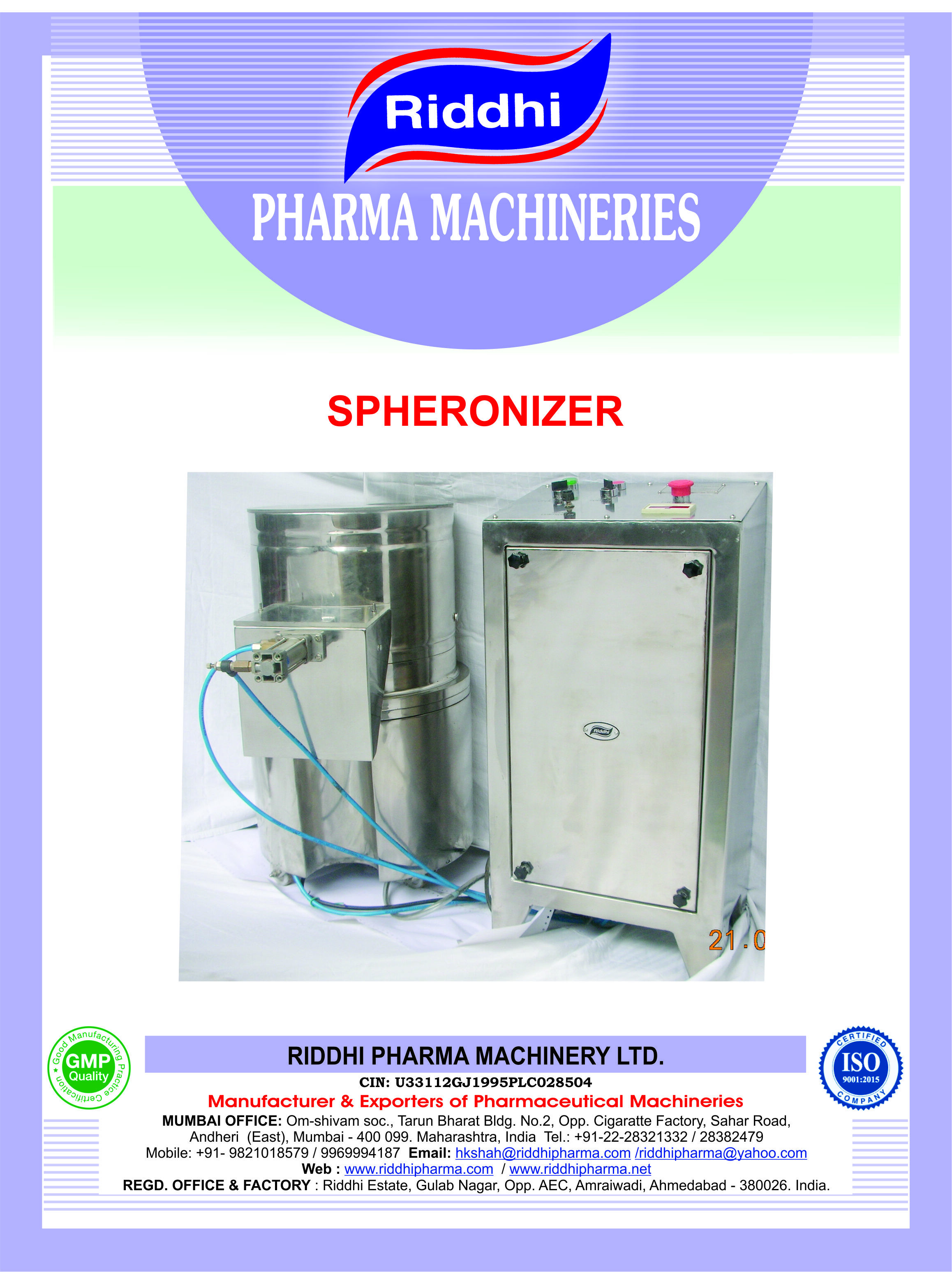

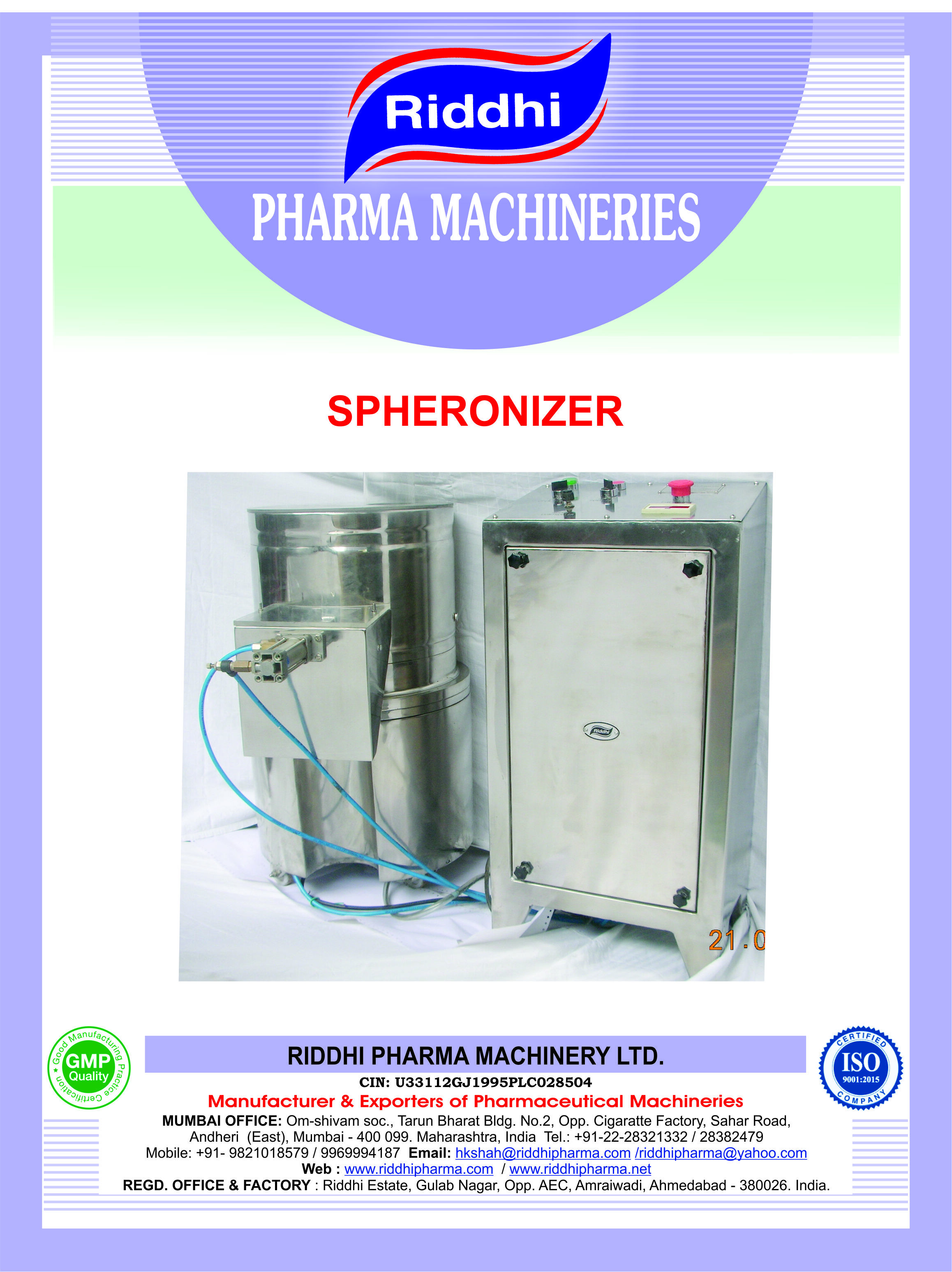

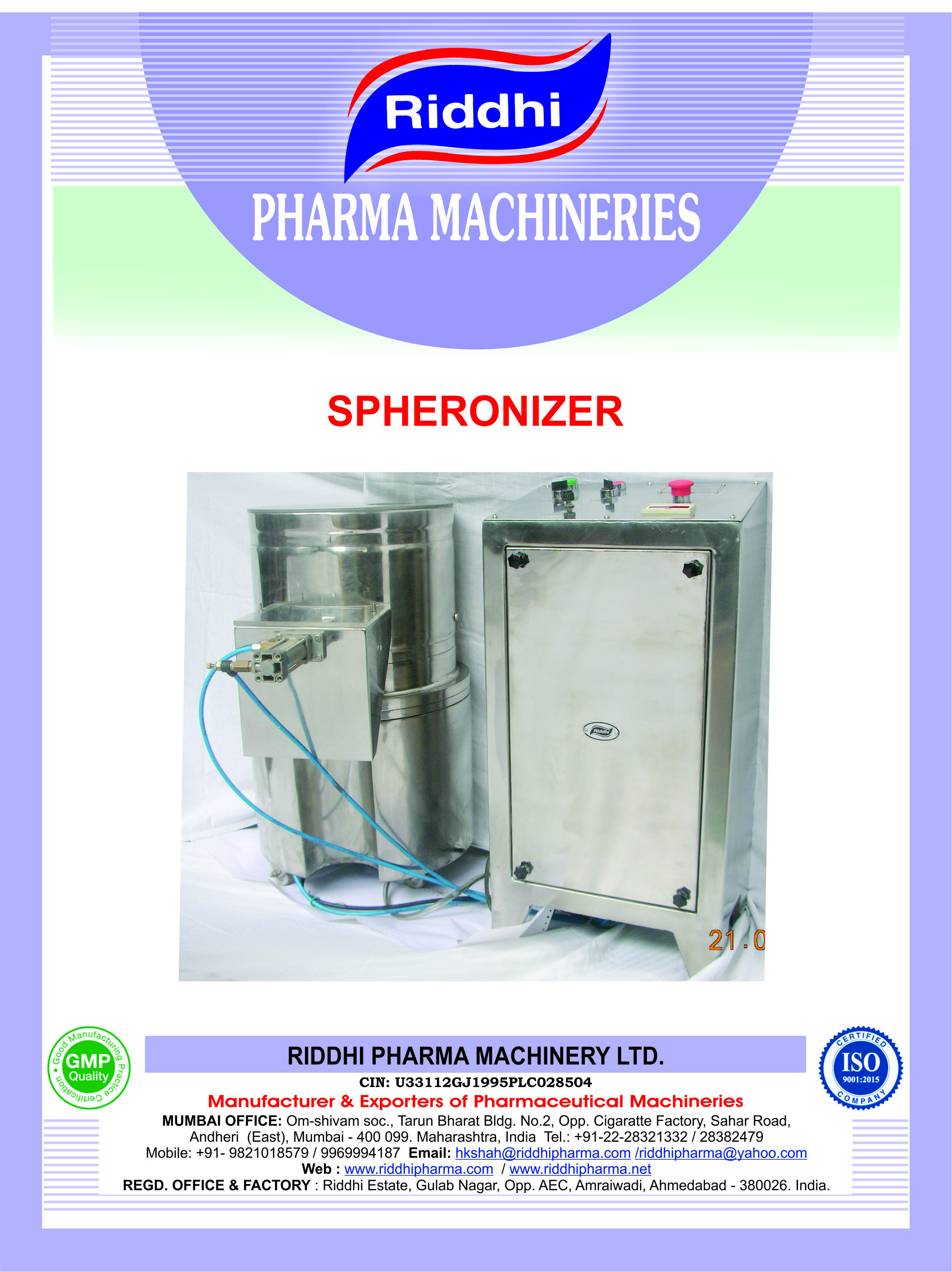

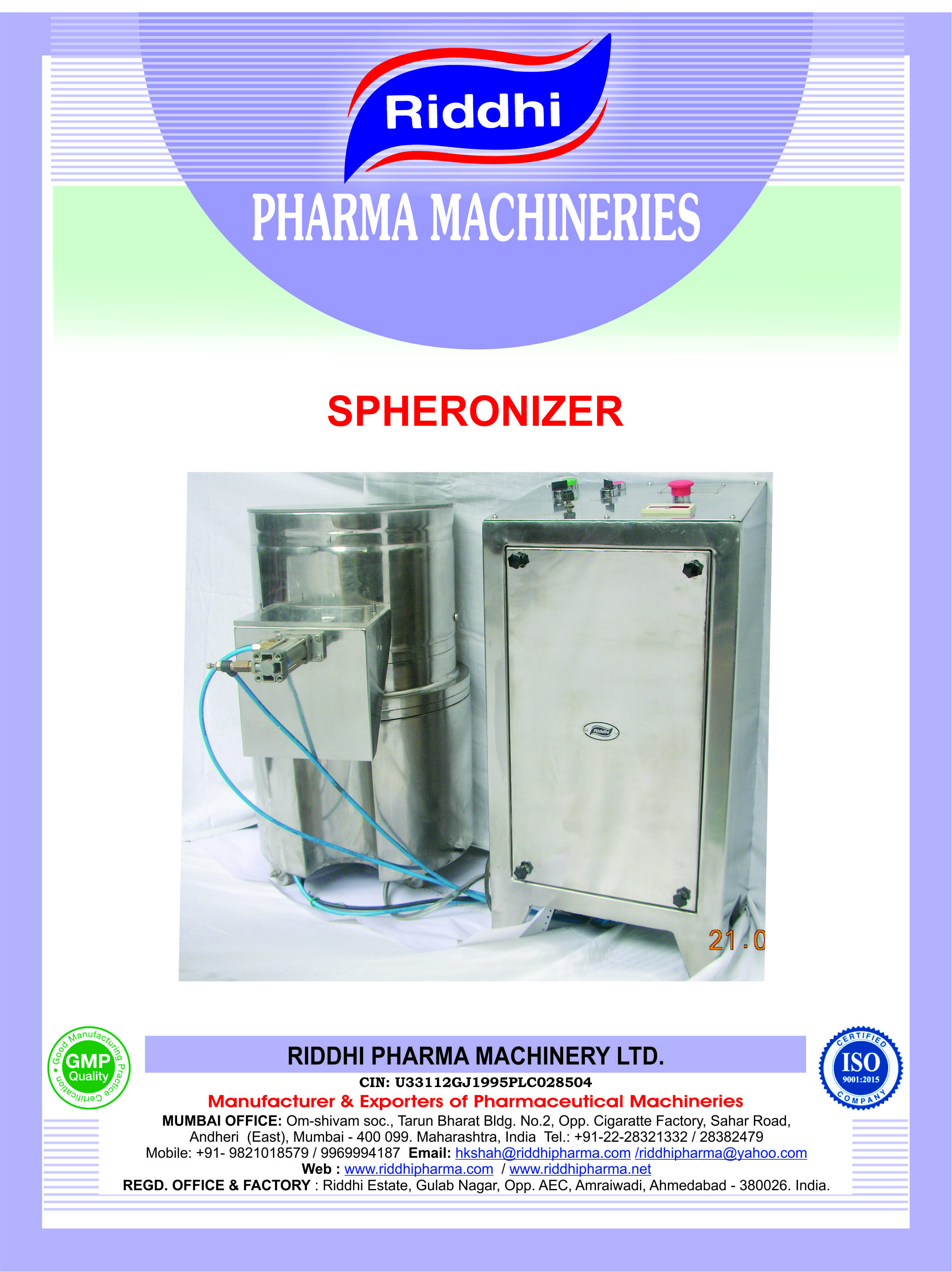

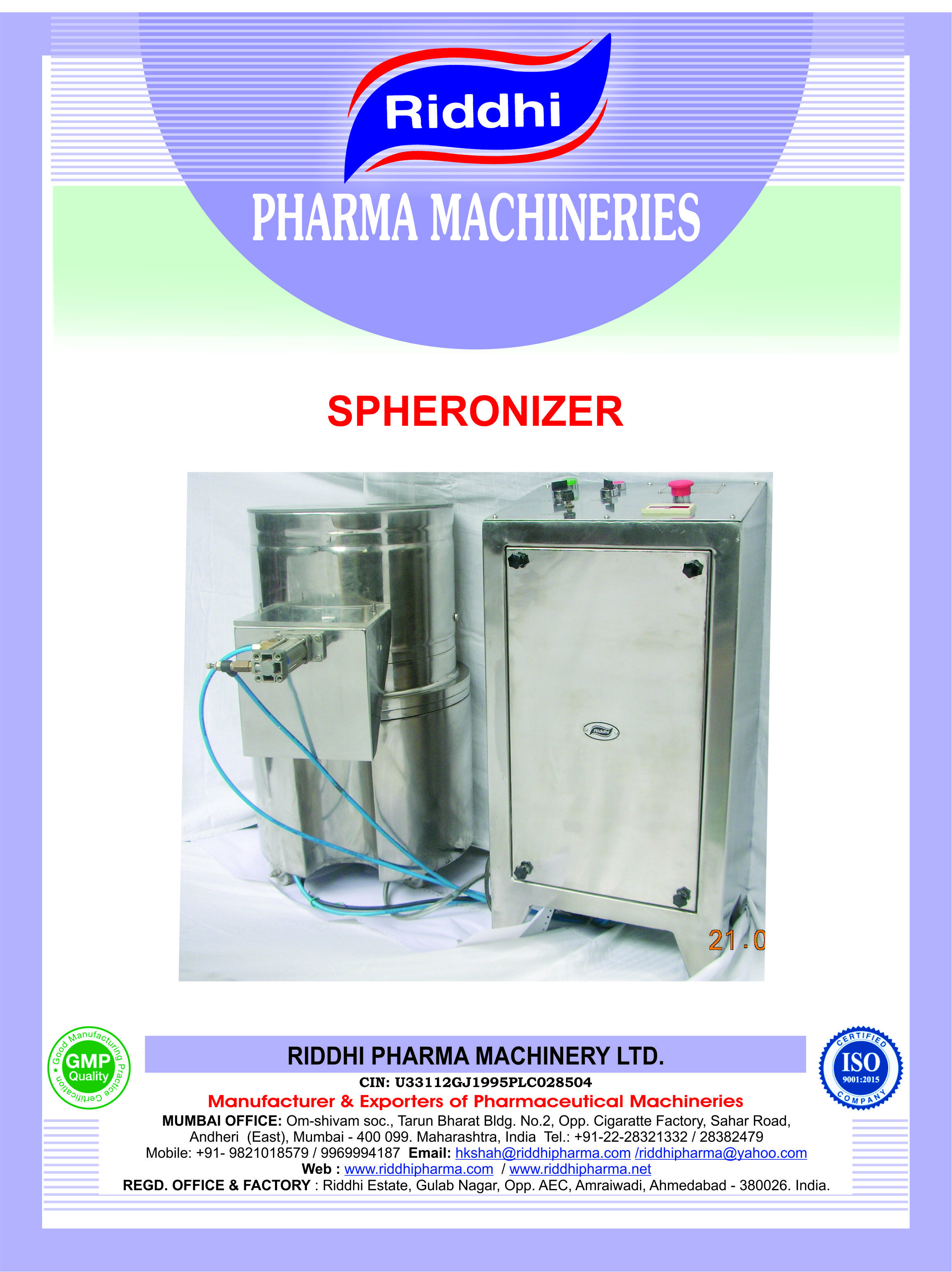

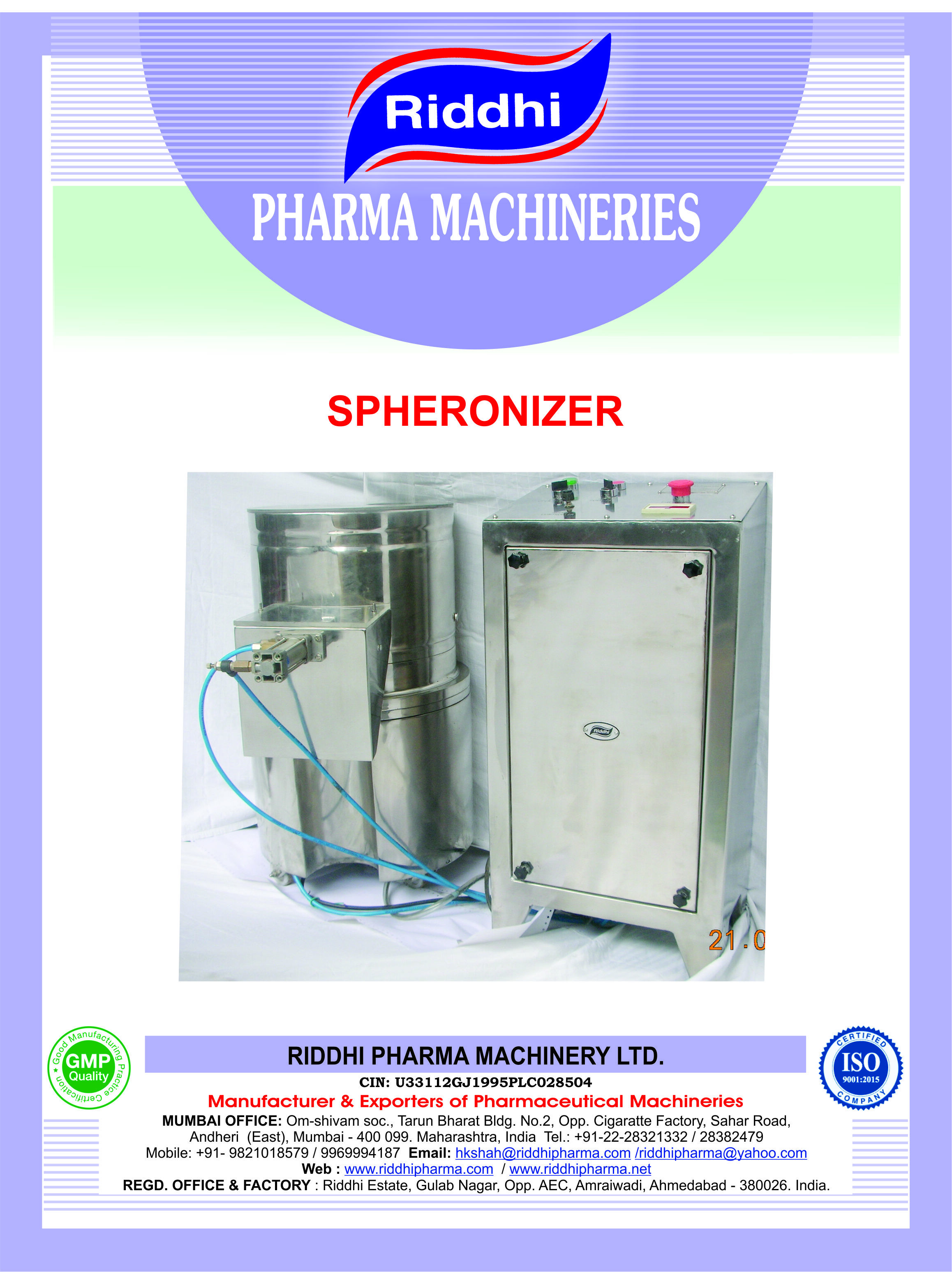

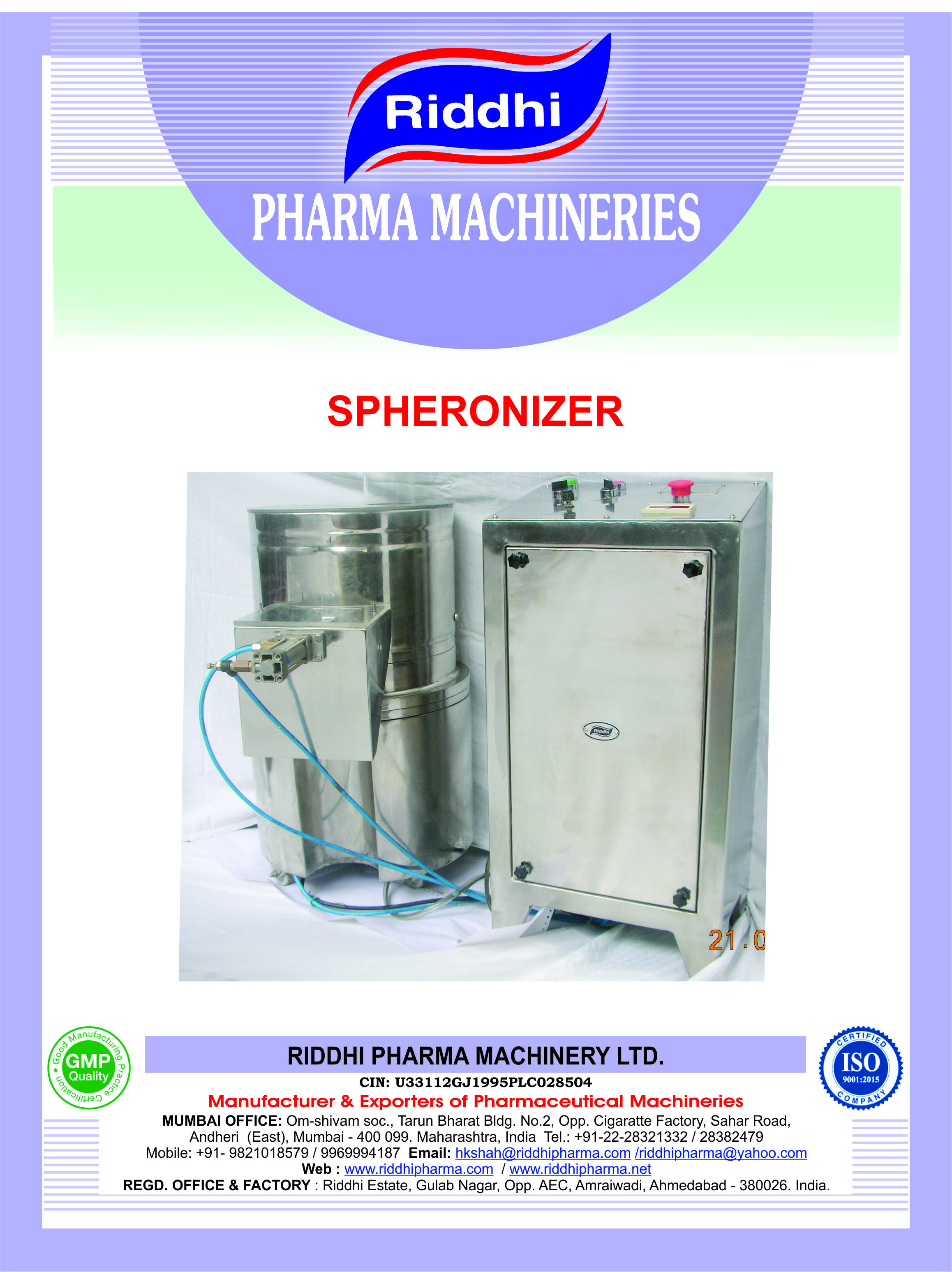

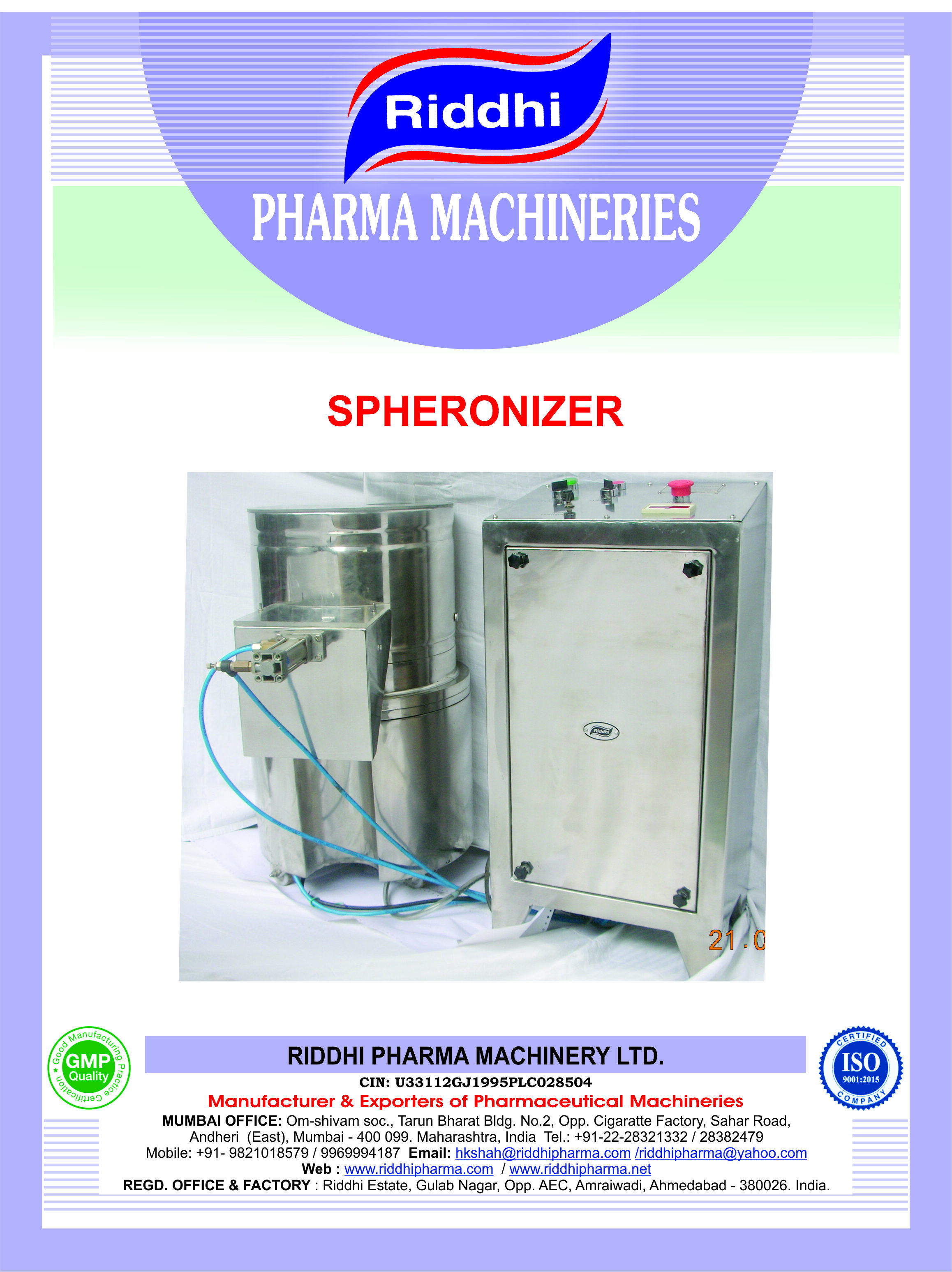

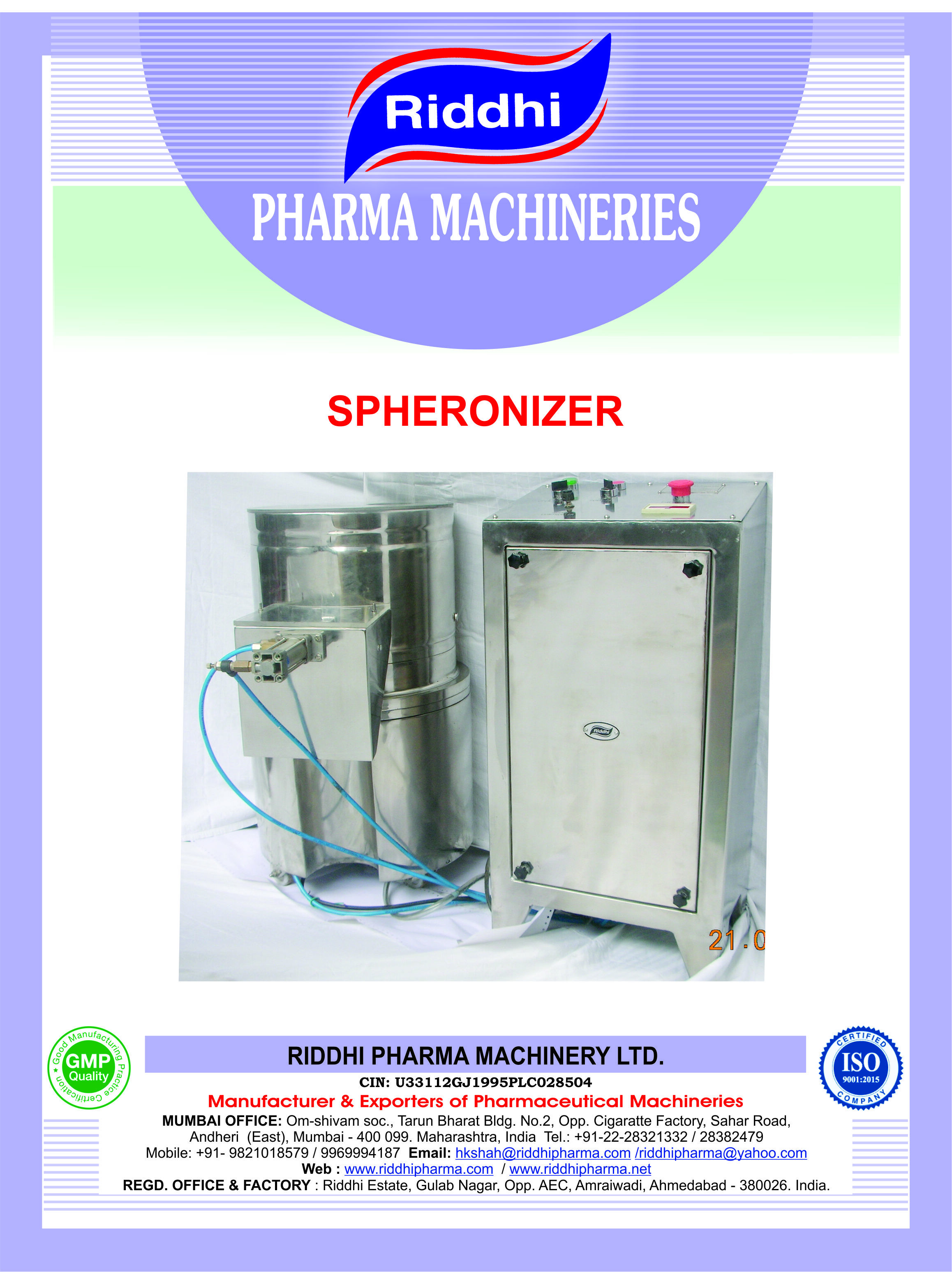

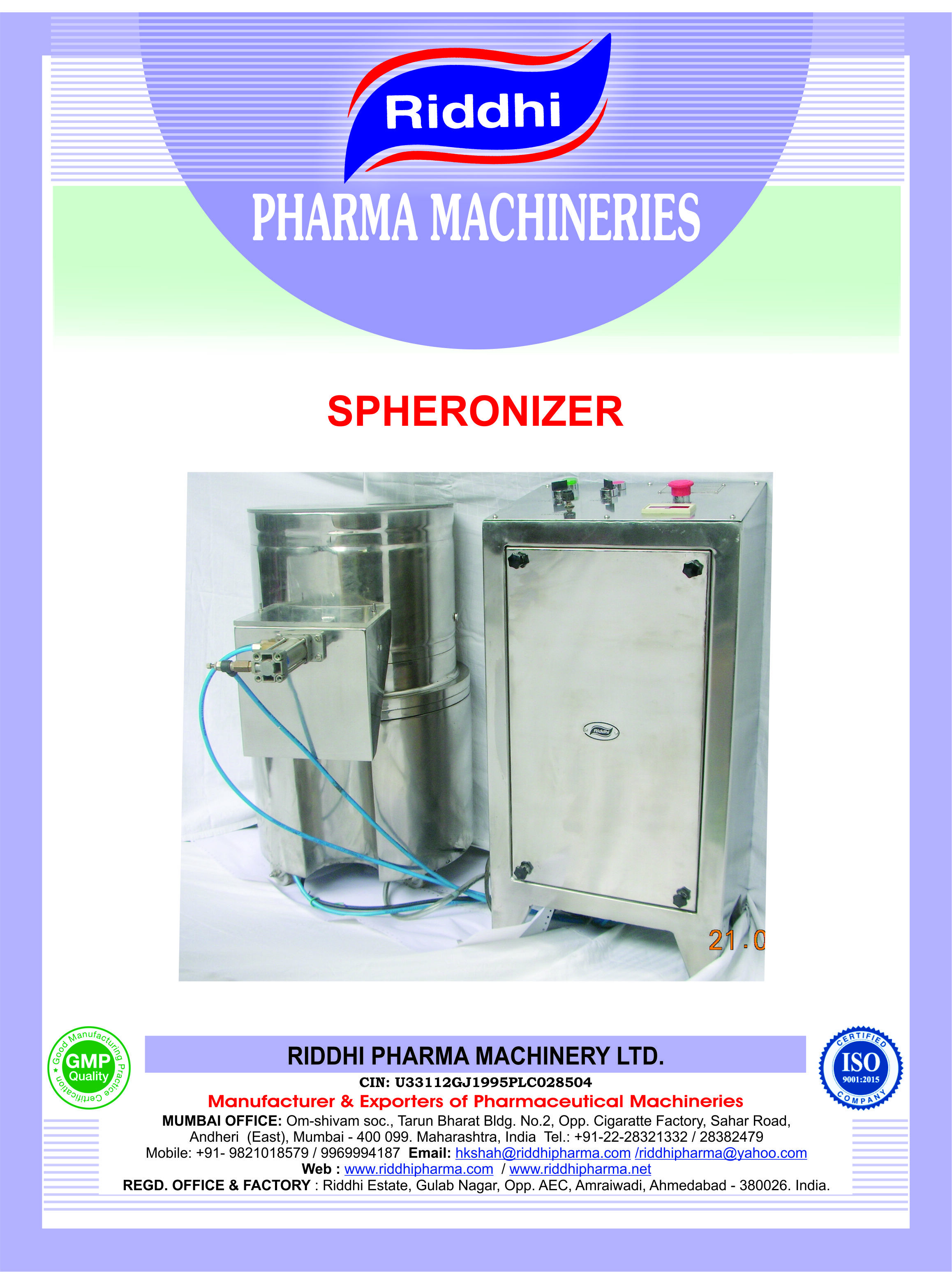

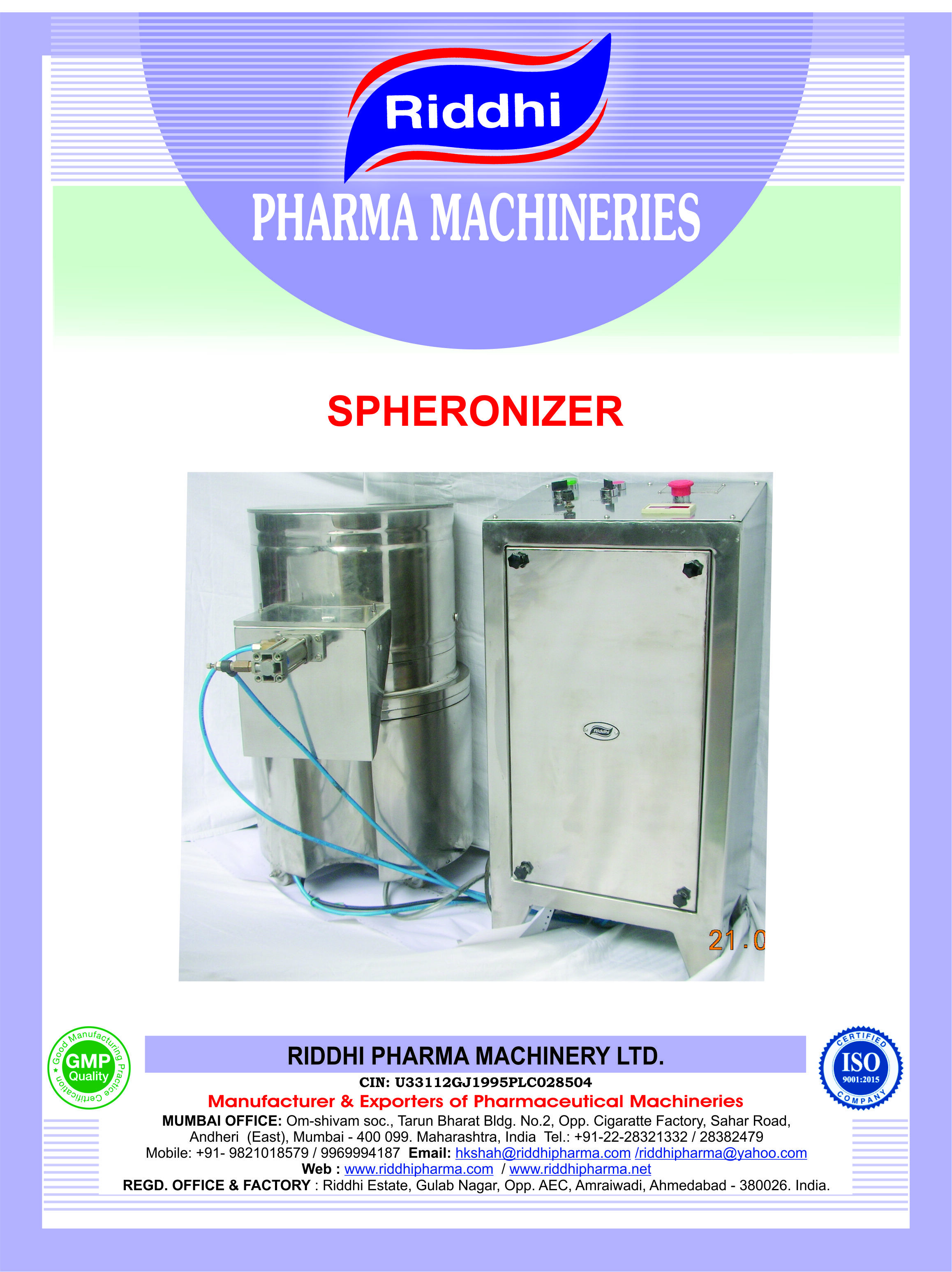

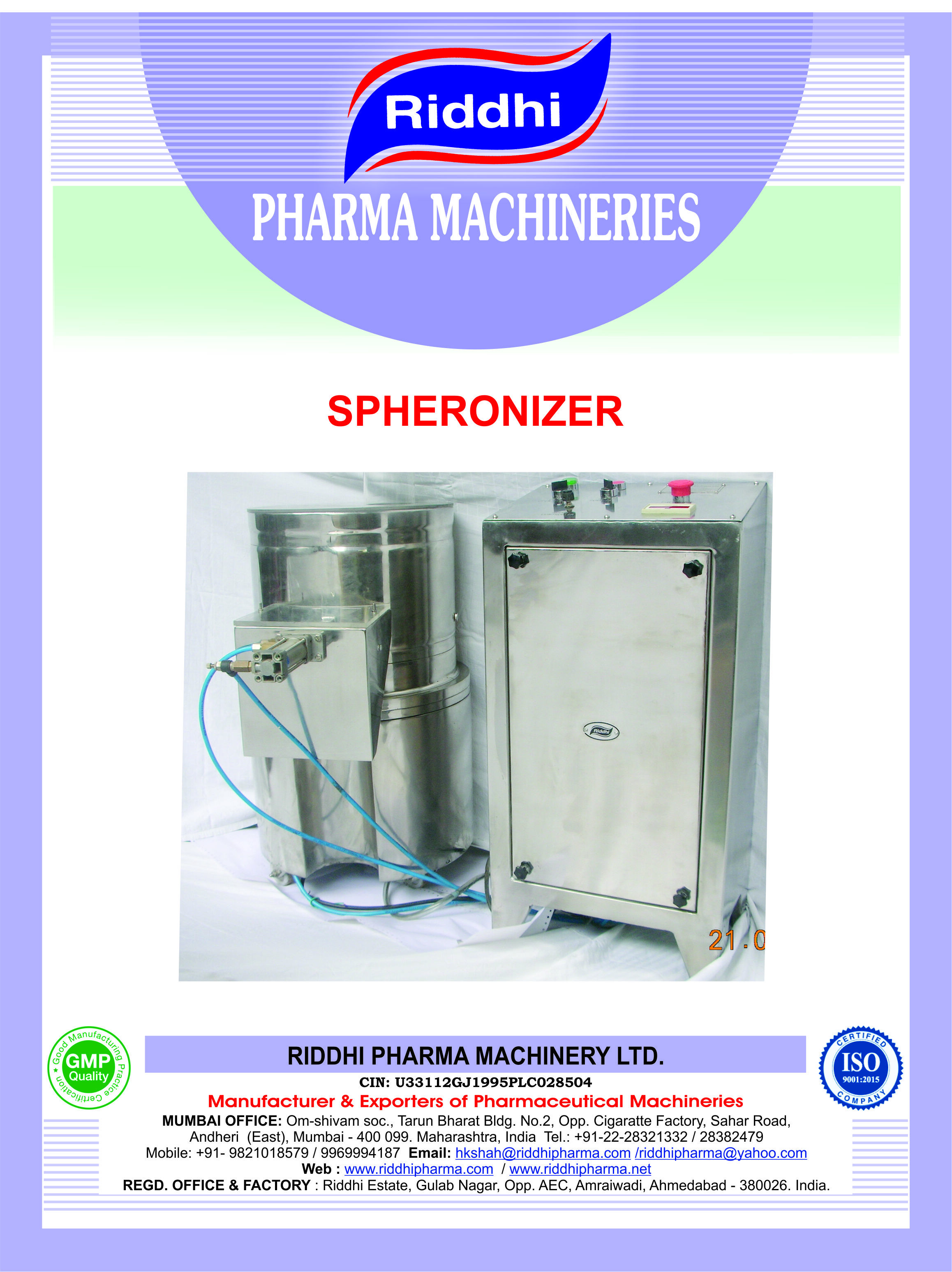

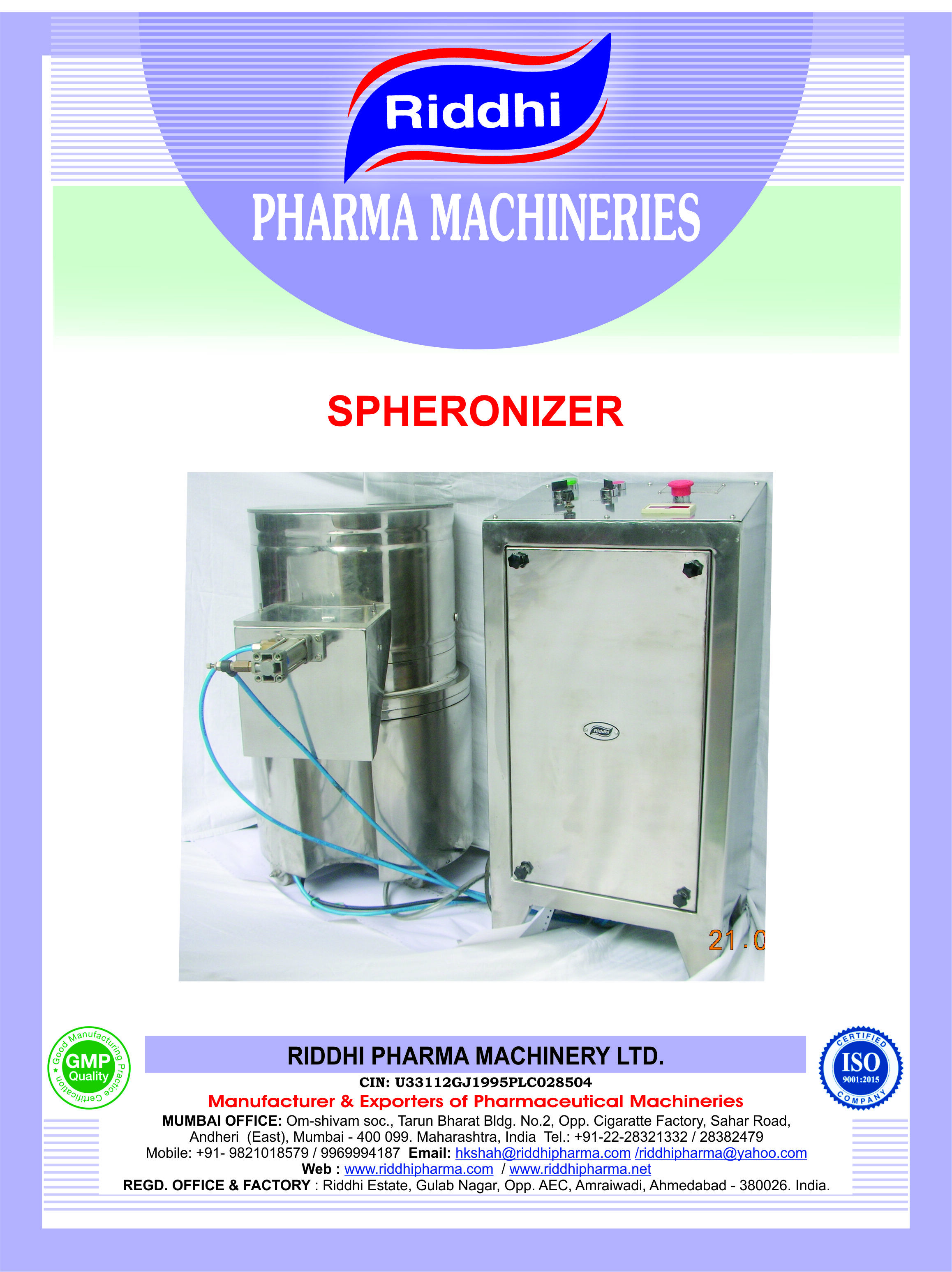

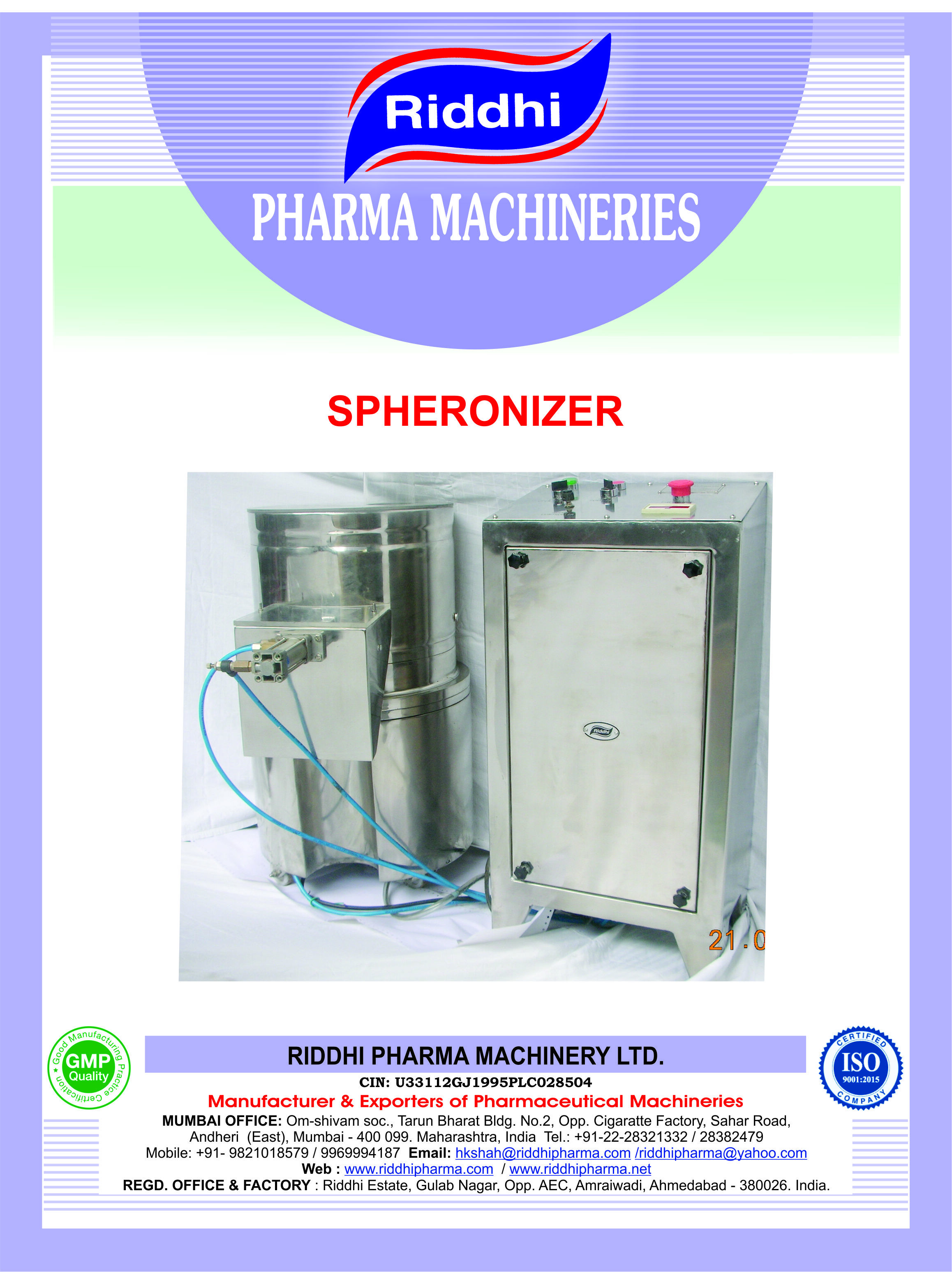

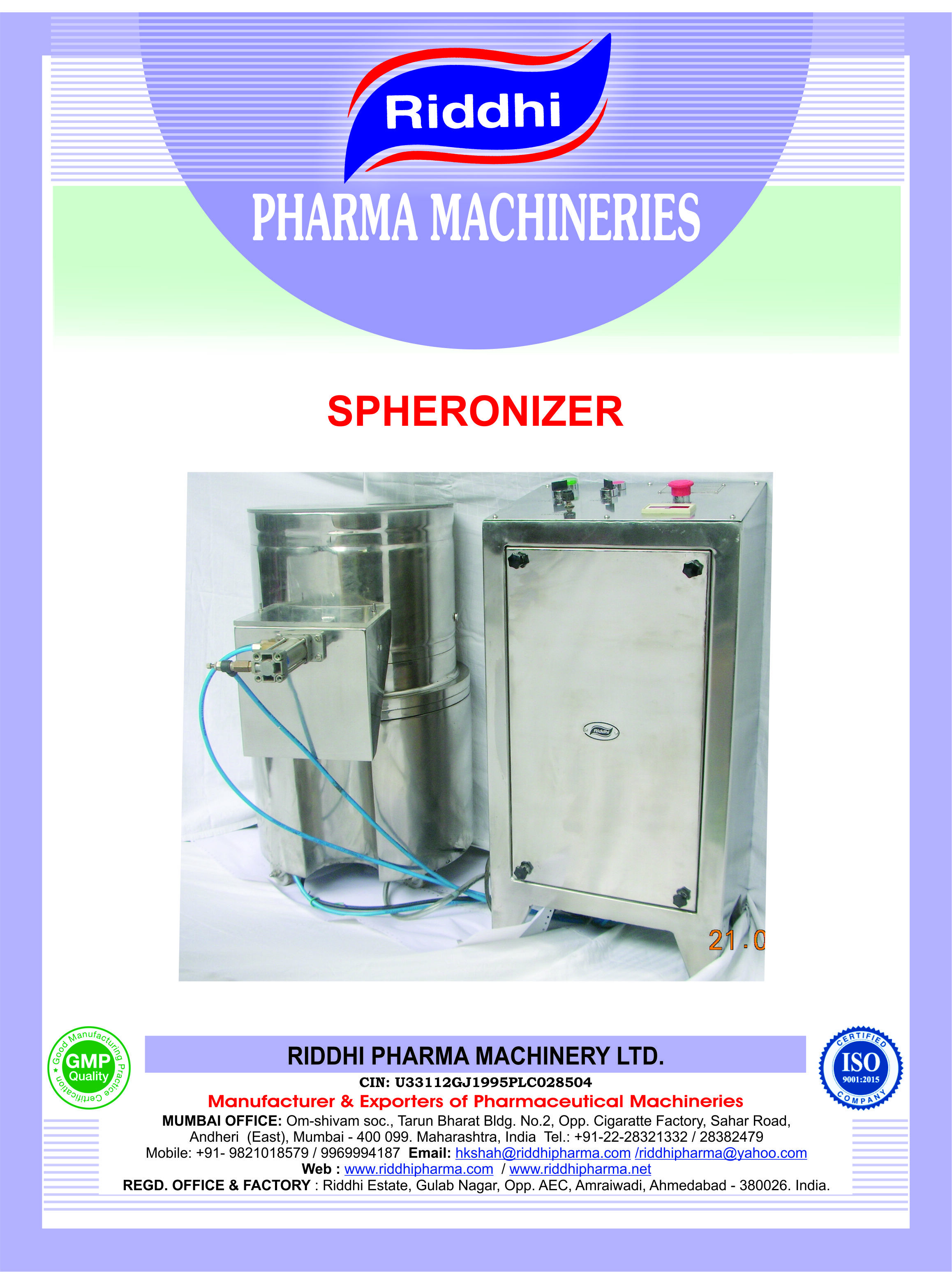

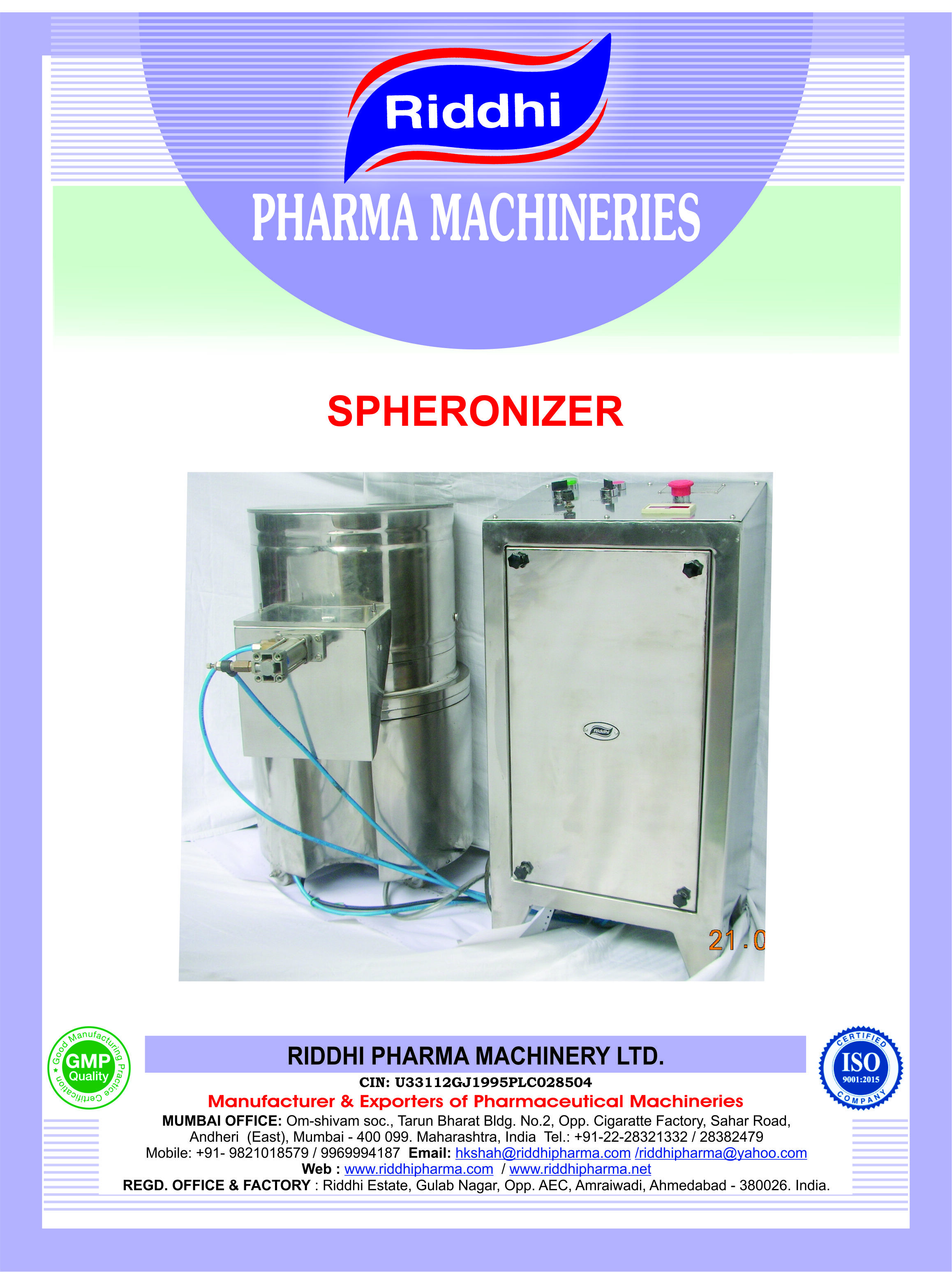

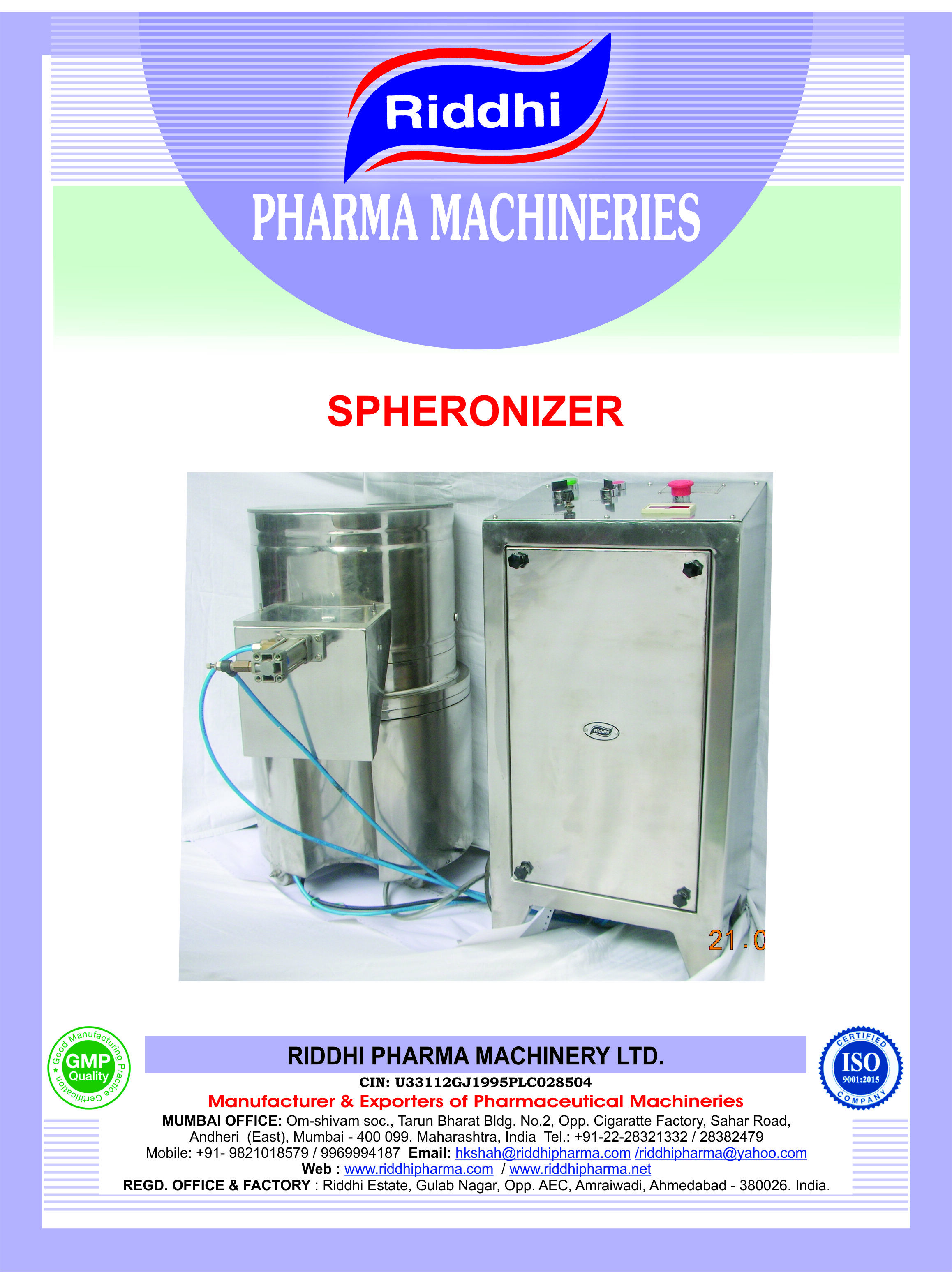

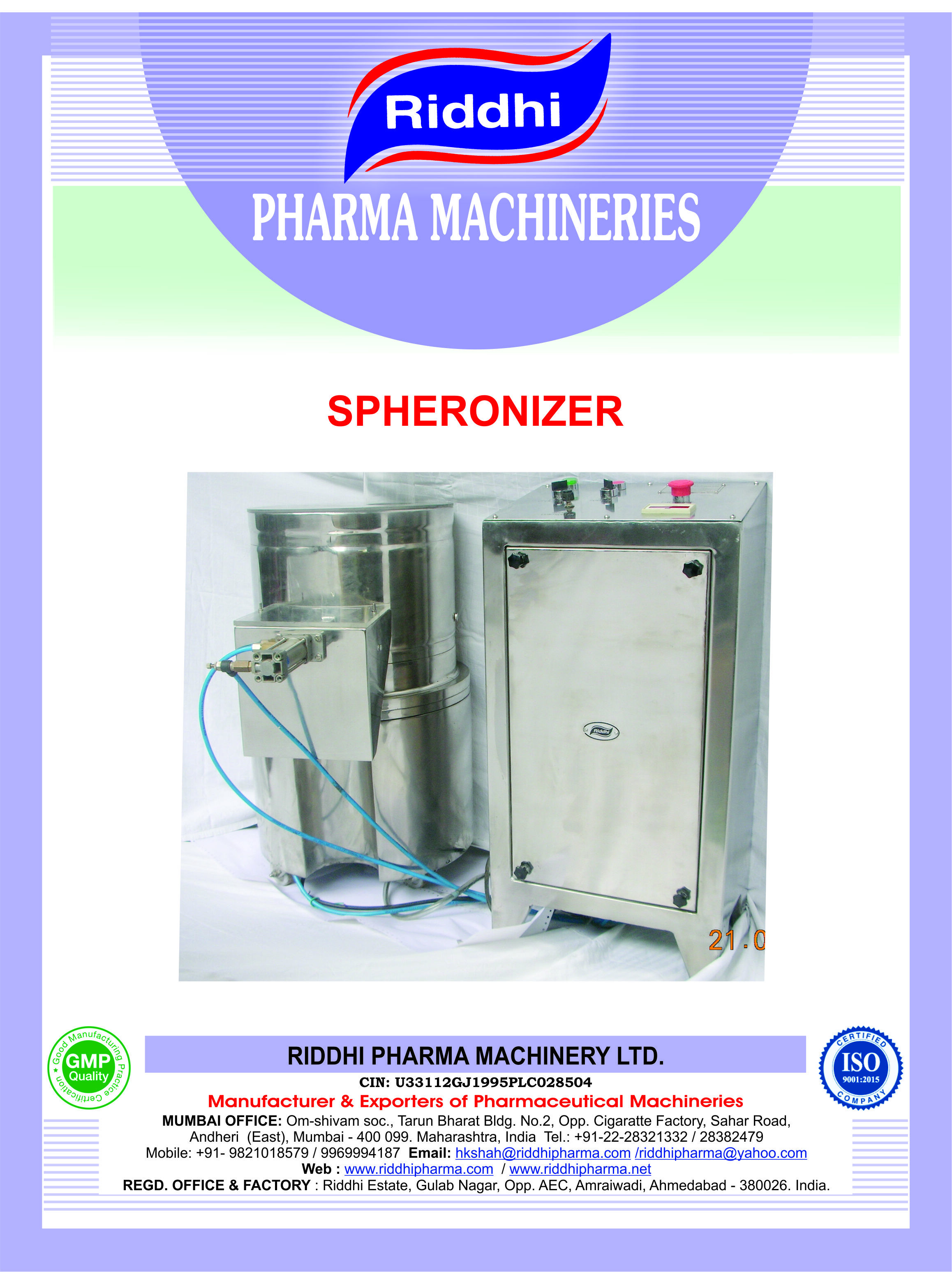

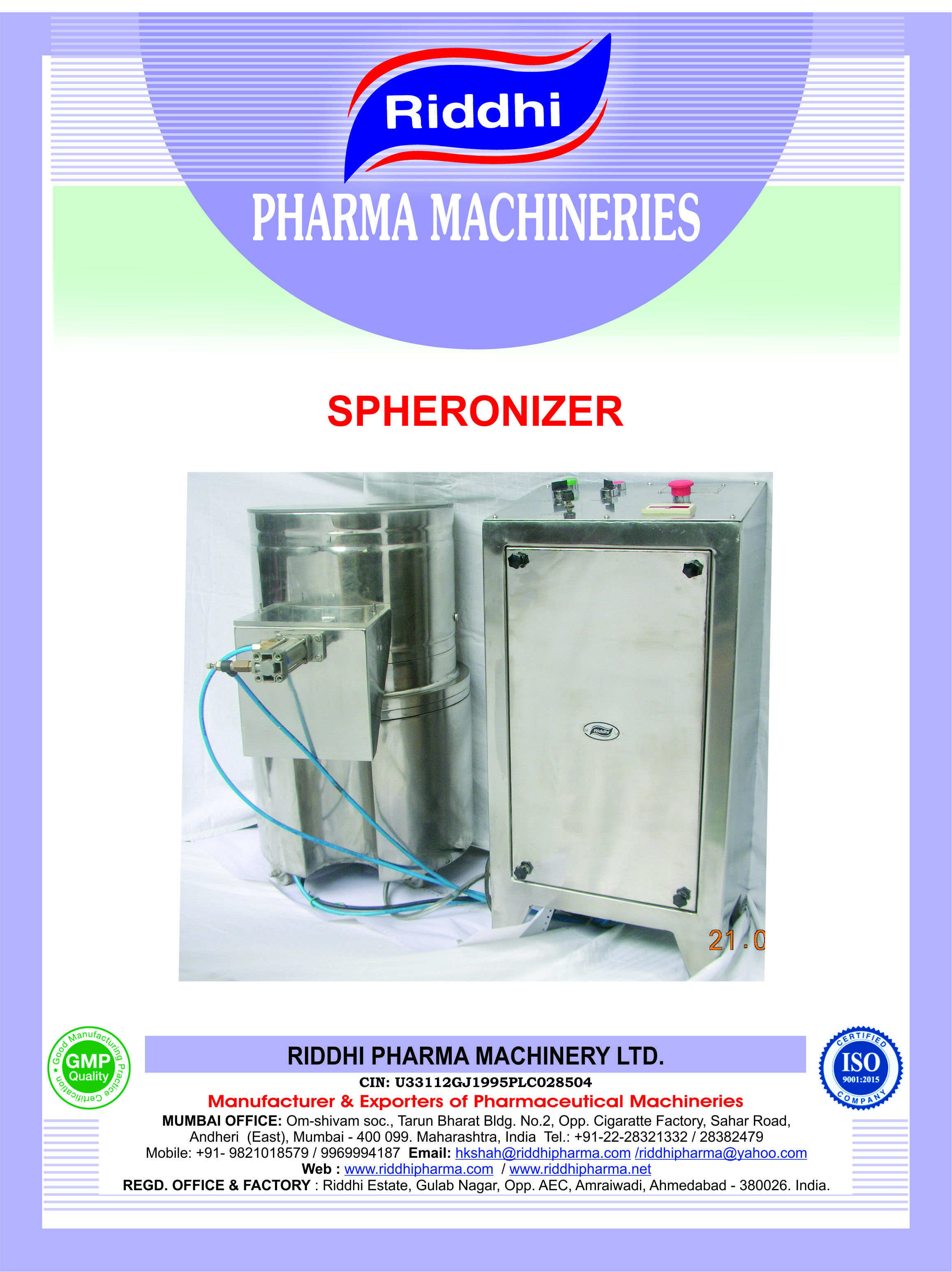

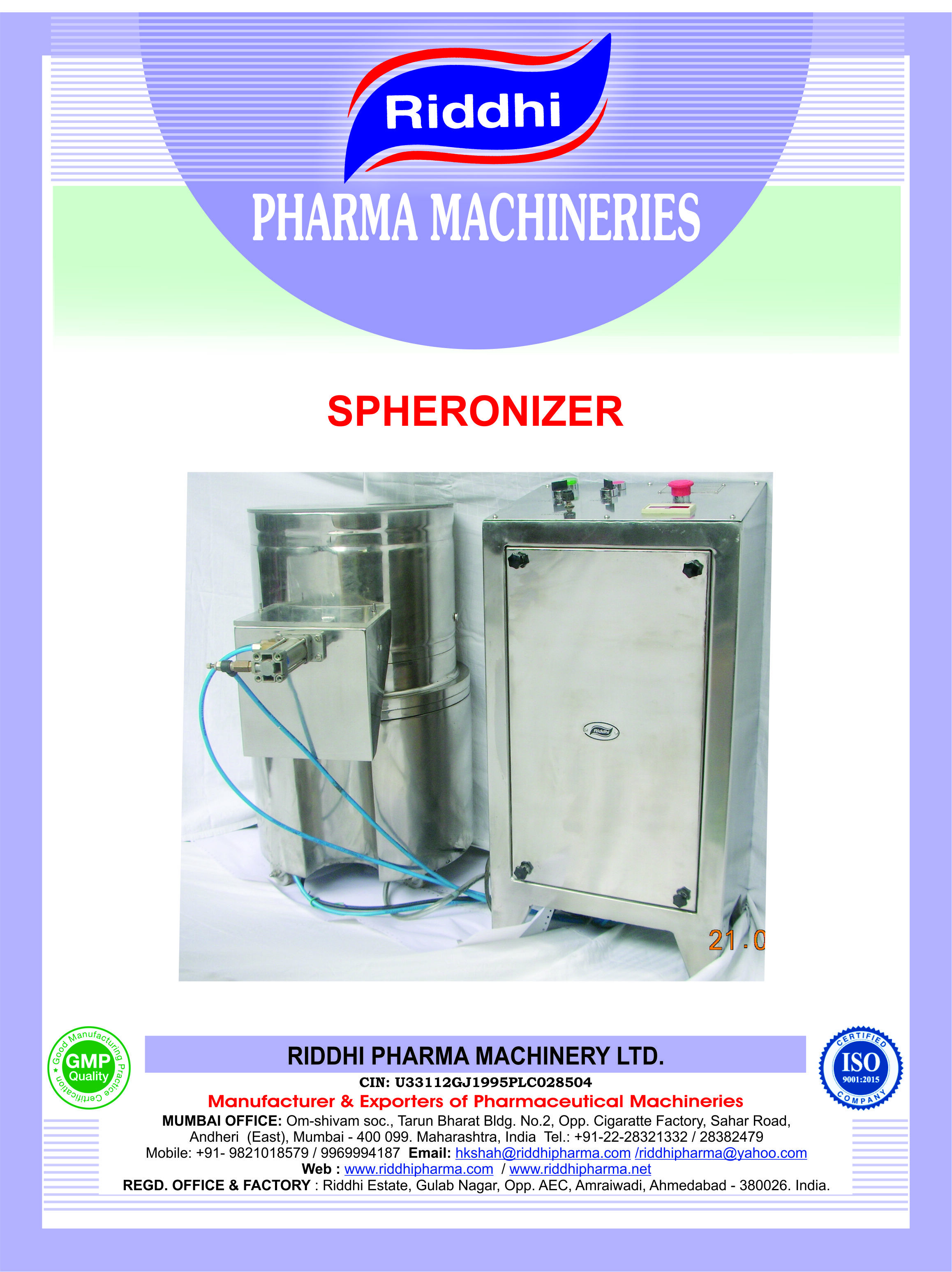

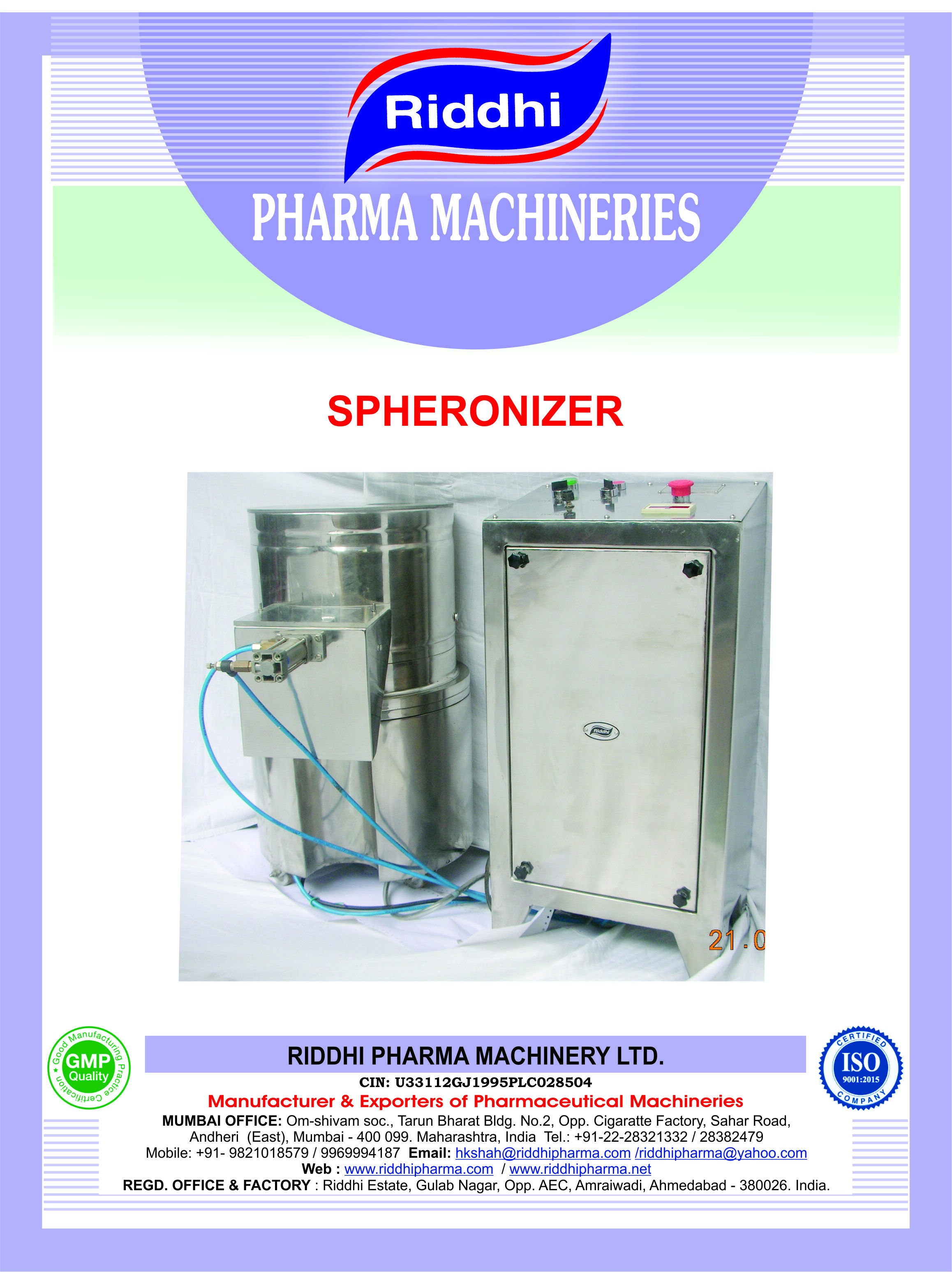

SPHER O DIZER

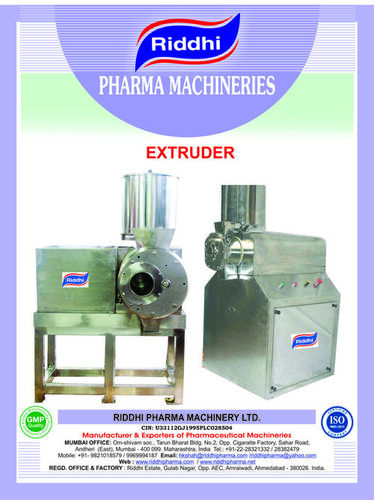

We are one of the pioneer Pharmaceutical Machinery Manufacturers from India We manfuacter Pallet Making Machine which is called Spehrodiser from the extruder small sticks are achieved Which are further put into sperodiser for achieving pallets which are used for drug layering of sustained release productsTechnical Offer

The machine consists of a round disc with a vertical shaft spinning at high speed at the bottom of cylindrical chamber The cylindrical drum is called bowl and the spinning disc is called a friction plate The friction plate has a groove pattern to increase the friction with the product When the extrudes are charged into the spherodizer they ate thrown to the end of spinning plate by centrifugal forces By the contact with the plate the extrudes are cut into short cylindrical segments which are gradually rounded by the collisions with the drum wall and the plate probabilities of fines generated during the process is there these fines will adhere on the surface of the spheres again they can get under the friction plate through the gap between the plate and the wall The fines generated under the friction plate will be discharged from the machine by means of a propeller after a certain retention time the particles have obtained the desired spherical shape then the discharge is via centrifugal force

The on going action of particles colliding with the wall and being the thrown back to the inside of the plate creates a rope movement of the product along the wall The continuous collision of granules with the wall and the friction plate will gradually turn cylindrical is essential for optimum spheronosation

The extrudes from the extruder are converted into spherical beeds due to the centrifugal force created by the high speed rotation of plate

The gap between the chequered plate and drum is reduced to minimum to avoid powders from falling down beeds being crushed during the Spheroidization process

The RPM of Spheroidizer and choosing correct plate with proper formulation are the key factors Each extrudate that comes in contact with the chequered plate in then broken in length to its diameter due to the tumbling rope effect of the beads get converted into spheres Compressed connection is provided to facilitate rope formation and avoid crushing of pellets

Technical Specification

| Mod el | Output | Motor HP | Die Roller |

|

| (Kgs/Qa) |

| Perf |

| RDETD 65 (lab) | 2-4 | 1 | 0.8-3 |

| RDETD 65 | 10-15 | 1.5 | 0.8-5 |

| RDETD 65 (Ex tended) | 15-25 | 2 | 0.8-5 |

| RDETD 100 | 50-90 | 5 | 1-7.5 |

| RDETD 130 | 200-300 | 7.5 | 1.5-10 |

| RDETD-60 | 20-30 | 2 | 0.6-5 |

| RDETD-100 | 60-100 | 5 | 0.6-7.5 |

| RDETD-130 | 250-350 | 7.5 | 0.6-10 |