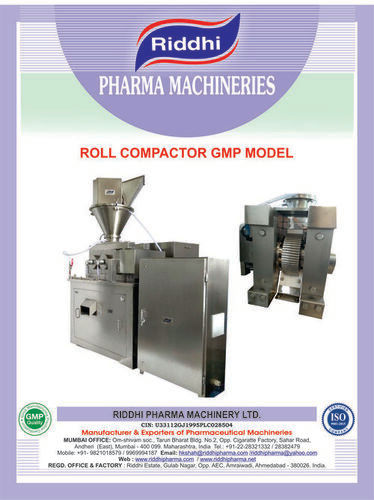

Multi Mill

Product Details:

- Type Other

- Material POWDER

- Capacity 200 KGS PER HOUR Kg/hr

- Computerized No

- Control Mode Automatic

- Voltage 440 VOLTS Milliampere (mA)

- Power 3 PHASE Milliampere (mA)

- Click to View more

Multi Mill Price And Quantity

- 3 Unit

Multi Mill Product Specifications

- ONE YEAR WARRANTY

- 200 KGS PER HOUR Kg/hr

- Other

- POWDER

- 125 KGS Kilograms (kg)

- Automatic

- STAINLESS STEEL

- 440 VOLTS Milliampere (mA)

- No

- 3 PHASE Milliampere (mA)

- 4 X 4 X5 Inch (in)

Multi Mill Trade Information

- FOB MUMAI JNPT PORT

- 4 Unit Per Month

- 4 Week

- SEA WORTHY PACKING

- All India

Product Description

Multi Mill Machine is widely used for wet and dry granulation pulverisation pharmaceuticals chemicals cosmetics ceramics colours dyestuff food products etc It also finds application in pesticides fertilizers spices detergents insecticides plastic and resins industries

Operation

It operates on the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to get the required size reduction Material fed in the hopper goes down to the processing chamber where it moves to the periphery and passes through the screen radially and tangentially Finally the processed material gets collected in the container kept below the processing chamber Output and quality of the final product depends on three main factors

- Shape of beaters knifeimpact edges

- Speed

- Screen

Description

Unit consists of SS 304 quality hopper and processing chamber can be provided is SS 316 quality at extra cost with beaters assembly motor reversible switch DOL starter four speed step pulley Suitable screen with painted pillar mounted on base plate with castors

Salient Features

Direction of beaters can be changed by reversible switch from knife to impact forward and viceversa All contact parts can be easily and quickly dismantled and cleaned Machine is designed for continuous operation Cylindrical screen for higher output Castors provided for mobility Flame proof electricals can be provided at extra cost Beaters and scrapper blades of SS 410 quality are hardened and hard chrome plated

| Multi Mill | Gmp Model |

| Model | RDMM |

| Output | 50 to 200 kgshr |

| Rotor Speed | 750 1500 2300 3000 RPM |

| Screen DiaI | D 260 mm x HT 135 mm |

| Electricals | 3 HP 1440 rpm |