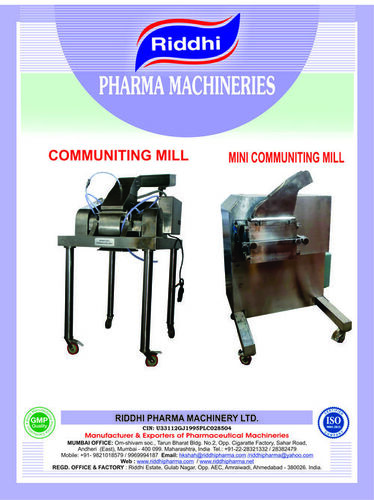

Communiting Mill

Product Details:

- Type Other

- Material stainless steel

- Capacity 800 KGS PER HOUR Kg/hr

- Computerized Yes

- Control Mode Automatic

- Voltage 440 VOLTS Milliampere (mA)

- Power 3 PHASE Milliampere (mA)

- Click to View more

Communiting Mill Price And Quantity

- 2 Unit

- 325000 INR/Unit

Communiting Mill Product Specifications

- STAINLESS STEEL

- 800 KGS PER HOUR Kg/hr

- ONE YEAR WARRANTY

- 750 KG Kilograms (kg)

- 3 PHASE Milliampere (mA)

- 440 VOLTS Milliampere (mA)

- stainless steel

- Yes

- Automatic

- Other

Communiting Mill Trade Information

- MUMBAI JNPT PORT

- 1 Unit Per Month

- 6-8 Week

- SEA WORTHY PACKING

- All India

Product Description

APPLICATION :Riddhi mill has been specifically designed for wet and dry granulation, pulverization or dispersion of products or ingredients found in the pharmaceutical, Chemical and food industries.It is also finds application in Cosmetics, confectionery, Fertilizers, Insecticides, detergents and Electro flux Industries etc.

DESCRIPTION :Latest improvements in design makes this unit a truely GMP model and Versatile in operation & maintenance. Unit consist of S.S.304 quality hopper, feed throat and processing chamber (can be provided in S.S.316 quality at extra cost ) with beaters assembly , heavy duty motor, star deltastarter with overload relay, three speed step pulley, suitable screen , S.S. cladded base having tubular legs with castors optional jacket for the feed throat and processing chamber for cooling.

OPERATION :Product kept in the hopper slide down to the enclosed chamber, where it is milled in between beaters and screen to the required mesh/micron size which can be collected at the bottom of the container.Quality and output depends upon the three main variables

- Beaters shape (knife/impact forward)

- Speed and Screen size

Knife edge for coarse or large particles and impact or flatedge for finer particles. Highspeed for fine griding, lowspeed for coarser particles. A wide range of screens isavailable for various process needs.

Technical Specification

| Output : | 50 Kgs. To 800 Kgs Per Hour Depending on the Product and the Reduction Required in Size. |

| Rotor Speed : | 1000/2250/4500 Rpm. |

| Beaters : | 16 Nos Stainless Steel With Knife and Impact Edges |

| Screen Area : | 495 Mm X 135 Mm (66825sq.mm) |

| Motor : | 7.5hp/1400rpm/440v/50cs/3ph/ac |

| Starter : | Star Delta With No-load and Overload Protection. |

| Net Weight : | 400 Kgs. |

| Gross Weight : | 530 Kgs. |

| Dimensions : | 1230 X 760 X1575 Mm(Ht)49 X30 X62 Inch App. |

| Case Dimensions : | 1380 X1050 X1900 Mm(Ht) 55 X 42 X 75 Inch |