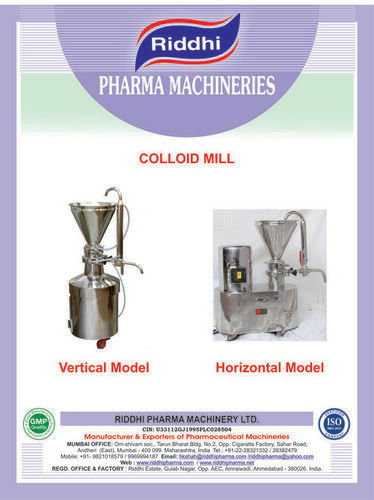

Colloid Mill

Product Details:

- Type Other

- Material LIQUID

- Capacity DEPENDING ON THE PARTICLE SIZE Kg/day

- Computerized No

- Control Mode Automatic

- Voltage 440 VOLTS Milliampere (mA)

- Power 3 PHASE Milliampere (mA)

- Click to View more

Colloid Mill Price And Quantity

- 2 Unit

- 150000 INR/Unit

Colloid Mill Product Specifications

- DEPENDING ON THE PARTICLE SIZE Kg/day

- 75 KGS Kilograms (kg)

- LIQUID

- 3 PHASE Milliampere (mA)

- ONE YEAR WARRANTY

- No

- Other

- Automatic

- STAINLESS STEEL

- 1.5 X 1.5 X1.75 Foot (ft)

- 440 VOLTS Milliampere (mA)

Colloid Mill Trade Information

- MUMBAI JNPT PORT

- 4 Unit Per Month

- 4-6 Week

- SEA WORTHY PACKING

- Australia North America South America Eastern Europe Western Europe Middle East Central America Africa Asia

- All India

Product Description

Colloid Mill Machine

Technical Offer

RIDDHI Colloid Mill is suitable for Homogenising Emulsifying Dispersing Mixing Comminuting of liquids to highly viscous products It is based on rotor stator principle It is available in plain as well as Water Jacketed model which is suitable for heat sensitive products Flame proof electrical can be supplied on demand at extra cost

Operation

Product is fed to the operating area of rotor having a speed of 3000 rpm by specially designed feed device The product is processed by high shear pressures friction between the stator rotor is also subjected to intensive vibration which exerts their force on it by means of pressing releasing actions due to the slightly deviating tapering of the milling surfaces of stator rotor the angular gap becomes narrower towards the discharge section This processed product continuously leaves the mill through the drain pipe if required it can be recirculated

Salient Features

- All contact parts are made out of SS 304 SS316 on demand at extra charges No casting are used for avoiding contamination problems

- Coupling provided between motor shaft rotor shaft for ease in maintenance

- Three oil seals between the Motor the processing chamber to prevent liquid going in the motor winding Resulting in the burning of the motor

- Modified design of semi concave teeth in rotor stator reduces the motor HP gives better performance in size reduction without damaging the product

- Extended bearing housing specially designed to facilitate fine adjustment of bearing clearances or back lash to avoid metal to metal contact of rotor stator This unique design provides smooth consistence all round performance ong life of rotor stator

- Leak proof neoprene sealing device

- Three way cock system for draining recirculation of liquids provided as standard Extra discharge spout provided as standard for viscous products

- DOL Starter with over load relay for protection against single phasing low voltage

- Contact parts can be easily dismantled for cleaning

- Special design facilitates adjustments of the grinding gap by an exterior screw by means of handle even during operation

- Flame proof motor Flame proof rotary switch can be provided on request at extra cost

Technical Specification

Colloid Mill GMP Vertical Horizontal

| Model | RDCM3 |

| Output | 120 to 12000 kgsshift |

| Particle size reduction | 5 to 10 Micron |

| Hopper Capacity | 15 ltrs |

| Reduction upto | 5 to 10 microns Particle Size |

| Electricals | 3 HP 2800 RPM 3 PHASE |

| Output | Depending upon material characteristics viscosity density micron size |