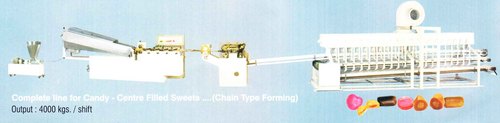

CANDY MAKING MACHINES

Product Details:

- Type Other

- Material Stainless Steel

- Control Mode Automatic

- Voltage 440 Volt (v)

- Color White

- Click to View more

CANDY MAKING MACHINES Product Specifications

- White

- Automatic

- Other

- Stainless Steel

- 440 Volt (v)

CANDY MAKING MACHINES Trade Information

- Western Europe Central America North America South America Eastern Europe Middle East Asia Australia Africa

- All India

Product Description

Owing to our deep knowledge about this domain, we are able to manufacture and export throughout the world our wide stock of Candy Making Machines. Our offered machines are used in the candy vacuum cooker that is used in bakeries and confectioneries for making hard boiled candies and caramel. These machines are available for the customers in various specifications, so as to fulfill their variegated requirements. The Candy Making Machines are quality tested and then delivered at the customers' place within the stipulated time frame.

Features:

- Excellent moisture removal

- Semi round grooved & knurled rope wheel sets

- High productivity

CANDY MAKING MACHINES

We manufacture candy making machines

Candy Vacuum Cooker

Our esteemed customers can get from us a complete line of Candy Vacuum Cooker which is used in bakeries and confectioneries for production of hard boiled candy, toffee and caramel varieties. Our cooker comprises of two main parts, upper one is the stainless steel pan with steam jacket for cooking and lower one is the tilting pan of copper or stainless steel for moisture removal.

Ingredients are loaded through manhole at upper vessel and cooked by steam which passes through jacket at 8 to 10 bar pressure. The cooked mass will be discharged in lower pan. Vacuumised lower vessel removes the moisture contents.

Tilting Cooling Plate

Cooling Plates are consists of fabricated structure having integrated eight cooling staggered chambers for cooling. As the tapped water passes through chambers the hot mass of Candy or Toffee mixture gets cooled which is spread on cooling Plate. The Cooling effect is controlled by reducing or increasing the flow of water.

The cooked and warm mass of Toffee / Candy is further proceed to form a thin and continuous rope on batch Roller Machine. The Batch Roller Machine is consisting of forward and reverse rotating stainless steel taper rolls. The rotating rolls moves the mass towards small end of rolls gradually and forms thin rope as per requirement. This rope is now ready to further proceed in to Rope Sizer Unit.

Rope Sizer Machine

The Toffee / Candy thin rope from Batch Roller further proceeds into Rope Sizer to form exact size rope as per Toffee / Candy size. Rope size machine consists of semi round grooved and knurled rope wheel sets. One set is provided vertically and other are horizontal. To form exact size of rope for Toffee / Candy size, the thin Toffee / Candy rope passes through decreasing rope wheel set and forms exact size of rope required.

Tablet Forming Machine

We are specialized in manufacturing and exporting our clients a precision engineered array of Tablet Forming Machine. These mainly consist one set of sizing wheels & tablet forming die. The rope from rope sizer machine enters in this sizing wheel and then into the tablet forming die to get the required shape of Candy as per die to get required shape of Candy as per die. It is suitable for forming seamless sweets with high depth and thickness. The new version of Tablet Forming Machine (Plast-o-Plast) is designed with spring type die with bigger & robust punches. Our Tablet Forming Machines offer noiseless and trouble free performance for a longer duration and can be availed at competitive prices.

3 Stage Cooling Conveyor

With years of domain expertise,we are manufacturing and exporting a varied assortment of 3 Stage Cooling Conveyor which is available in different weights, capacities, dimensions and specifications. Warm candies from the P-O-P are cooled in Cooling Conveyor. These consists of a blower fitted over the galvanised wire mesh of 4", 8" and 12" width. These 3 Stage Cooling Conveyors are preferred by customers for their rugged construction, compact design, easy installation and low maintenance.

AUTOMATIC CANDY WRAPPING MACHINE

MACHINE SPEED : UPTO 350 PER MINUTE ( DEPENDING UPON THE SHAPE OF THE SWEET AND PACKING MATERIAL