Auto Coater Machine

1800000 INR

Product Details:

- Type Film Coating Machines

- Material film, aqueous, sugar

- Capacity lab model to 60 inch Kg/hr

- Computerized Yes

- Control Mode Automatic

- Dimension (L*W*H) 8 x 9 x10 Foot (ft)

- Color STAINLESS STEEL

- Click to View more

X

Auto Coater Machine Price And Quantity

- 1800000 INR

- 1 Unit

Auto Coater Machine Product Specifications

- ONE YEAR WARRANTY

- 8 x 9 x10 Foot (ft)

- Yes

- Automatic

- lab model to 60 inch Kg/hr

- film, aqueous, sugar

- STAINLESS STEEL

- Film Coating Machines

Auto Coater Machine Trade Information

- FOB MUMAI JNPT PORT

- Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Cash in Advance (CID)

- Per Month

- Months

- sea worthy packing

- All India

Product Description

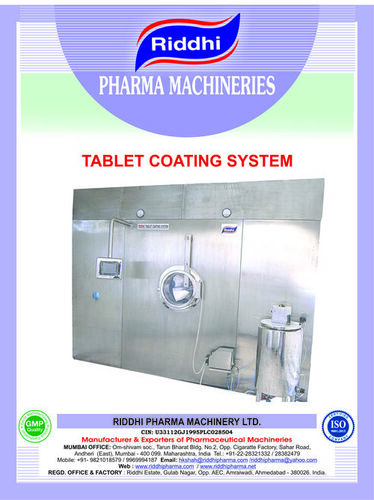

Tablet Coating System

Advanced technology and high efficiency Auto Coater Machine is designed to be used is pharmaceutical as well as food industries. It is available with high-end features with energy saving designs. It comes with safe to use and clean parts to ensure to provide perfect sugar coating of a range of pills, tablets, etc. In addition, it can also be used to coat aqueous, organic film, sugar film etc. It is available with fully automatic coating processes managed by PLC controls having HMI touch screen.

Features of Auto Coater Machine:

- Flexible batch operations with user friendly software

- Operation is done through PLC

- Designed from high quality SS and other material

- Perforated pan comes with half opening for high quality finish

Technical Specifications

| Technical specification | 660mm (24") | 940mm (37") | 1070mm (42") | 1220 mm (40") | 1525mm (60") | 1675mm (66") | |||||

| Working Capacity-KG (Considering bulk density 0.97 gm/cc) | 10-20 | 40-70 | 60-100 | 80-150 | 200-350 | 350-500 | |||||

| Pan Mouth Diameter -MM | 250 | 380 | 380 | 400 | 520 | 520 | |||||

| Pan Speed - RPM | 5-15 | 2-10 | 2-10 | 2-10 | 2-10 | 2-8 | |||||

| Main Drive FLP Motor - HP | 1 | 2 | 2 | 3 | 5 | 10 | |||||

| Hot Air Inlet Blower - HP | 1 | 2 | 3 | 5 | 7.5 | 10 | |||||

| Hot Air Fan Capacity - CFM | 350 | 1300 | 1600 | 2500 | 4000 | 5500 | |||||

| Steam Consumption in (Kg/Hr) At Pressure (Bar) | 15-20 2-4 | 40-60 2-4 | 50-70 2-4 | 80-100 2-4 | 120-140 2-4 | 16-180 2-4 | |||||

| Compressed air (CFM) At pressure 6 (Bar) q | 20 | 30 | 30 | 55 | 95 | 110 | |||||

Enter Buying Requirement Details